On-line quality control method of large mechanical product assembly based on machine vision

A quality control method and technology of large-scale machinery, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of large detection area and large amount of calculation in the detection process, and achieve the effect of improving adaptability and reducing the accuracy of cameras

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

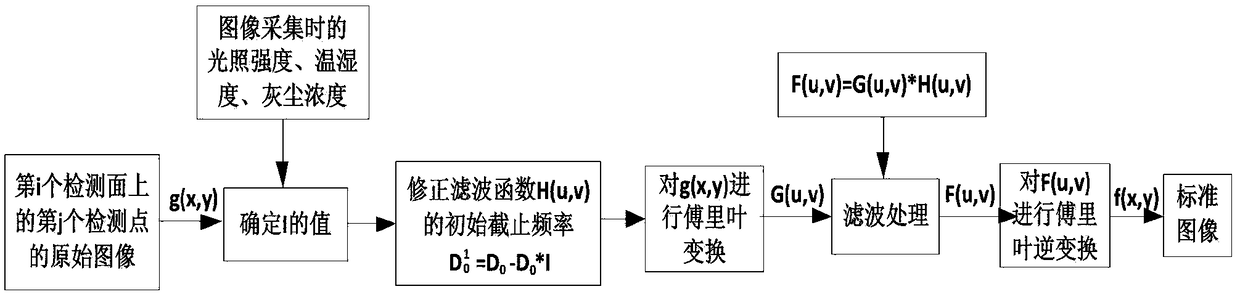

Method used

Image

Examples

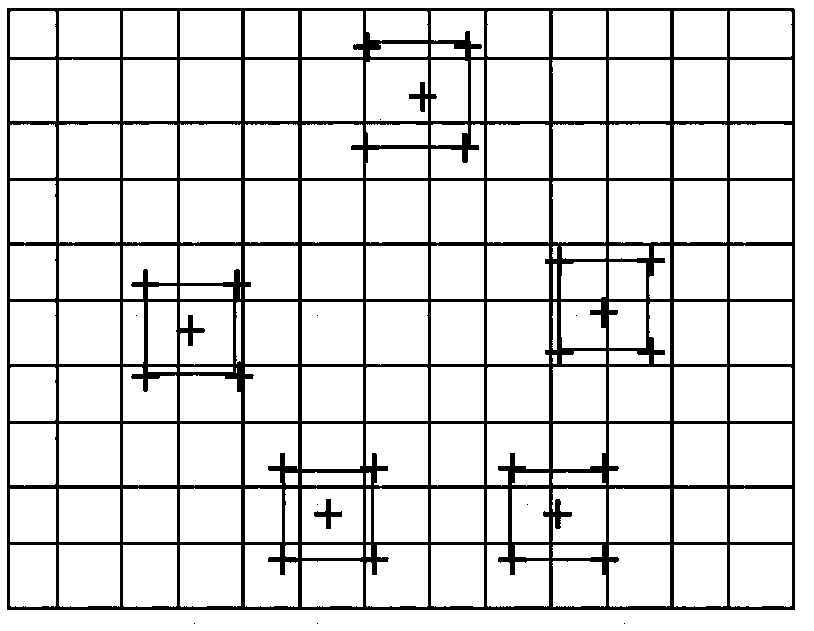

Embodiment Construction

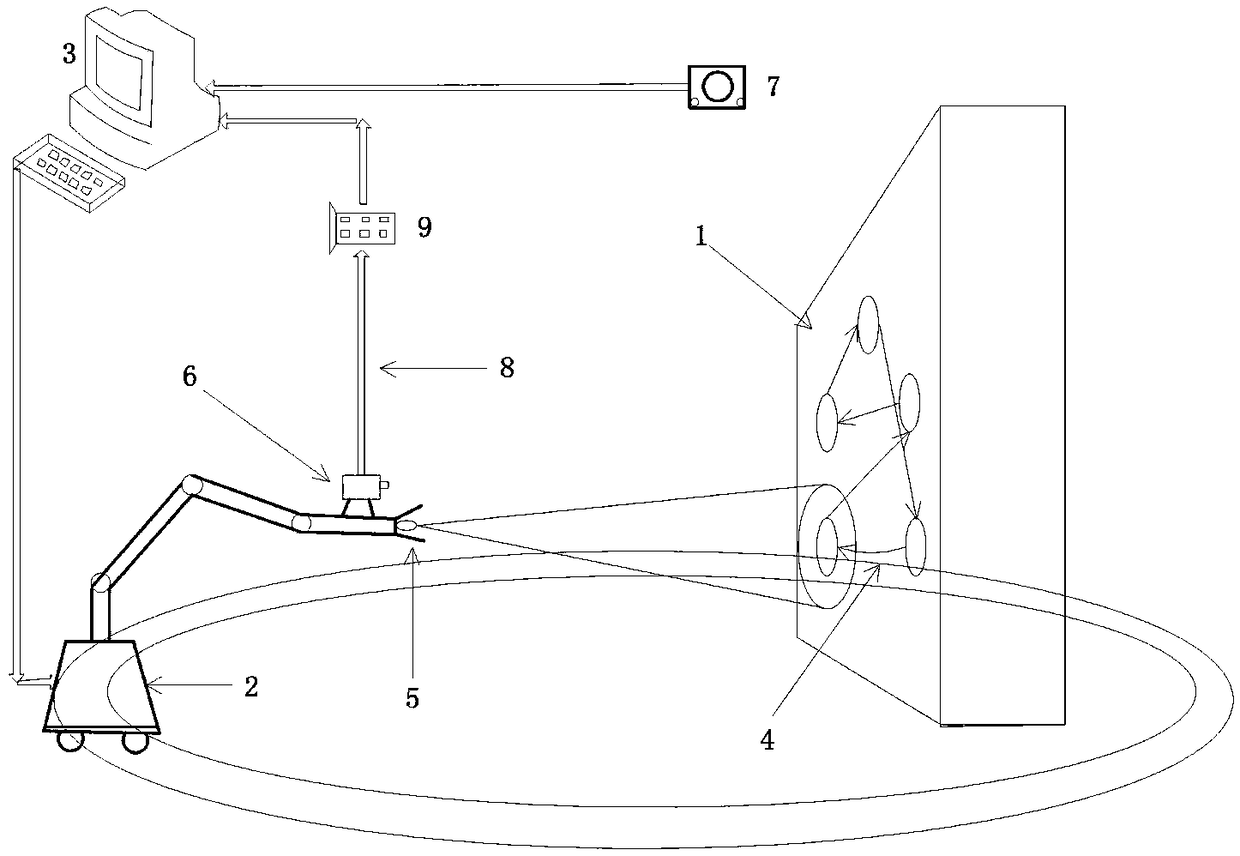

[0032] see image 3, the implementation of machine vision-based online quality control of large-scale machined product assemblies includes a large-scale machined product assembly 1, the large-scale machined product assembly 1 is placed in a fixed position, and the computer system 3 stores large-scale machined products All detection point positions and workpiece size information on all detection surfaces of the product assembly 1, assuming that the large-scale machining product assembly 1 contains n detection surfaces, and the i-th detection surface contains m i detection points, 1≤i≤n, and the size of the image of the jth detection point collected on the i-th detection surface is M×N; the robot 2 can perform orbital movement around the large-scale machining product assembly 1 , respectively reach the n detection surfaces of the large-scale machining product assembly 1, and the manipulator on the robot 2 can move according to the planned detection path 4; the visual sensor 5 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com