Production equipment including machine learning system and assembly and test unit

一种生产设备、试验器的技术,应用在具备机械学习器以及组装试验器的生产设备领域,能够解决多劳力和时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Hereinafter, the production facility of the present invention will be described with reference to the drawings.

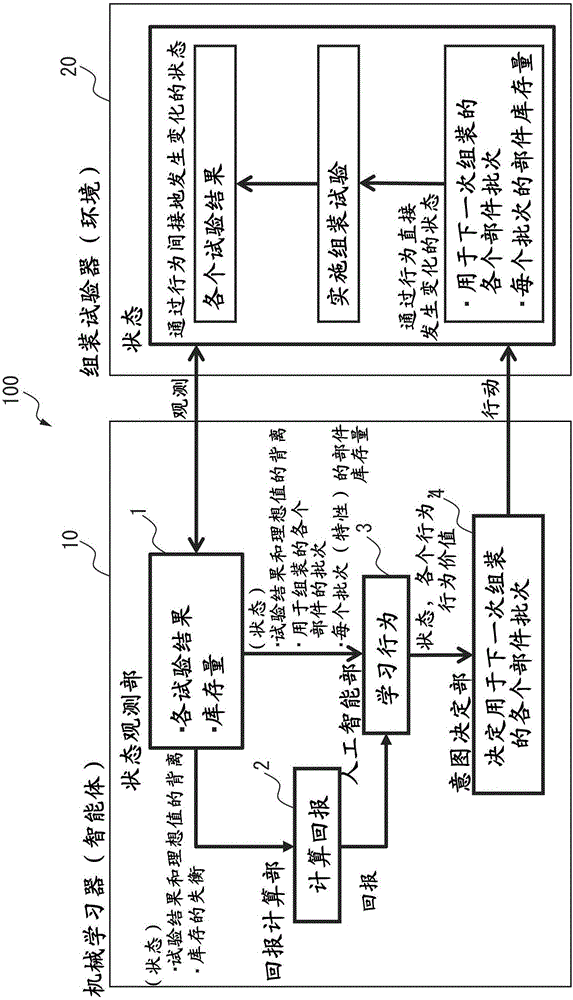

[0013] figure 1 It is a structural diagram of the production equipment of the embodiment of the present invention. The production facility 100 of the embodiment of the present invention includes a machine learner 10 and an assembly tester 20 . The machine learner 10 includes a state observation unit 1 , a reward calculation unit 2 , an artificial intelligence unit (hereinafter also referred to as a “learning unit”) 3 , and an intention determination unit 4 .

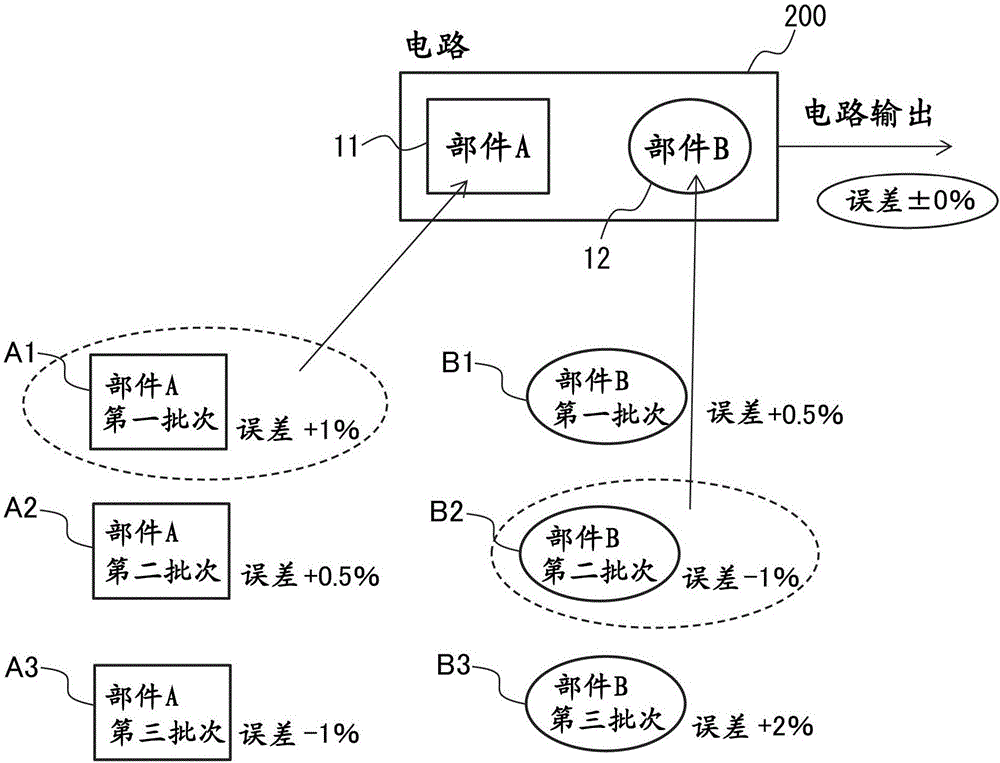

[0014] figure 2 It is a conceptual diagram of a process of producing a circuit by selecting a plurality of components from a plurality of component groups using the production equipment of the embodiment of the present invention. The assembly tester 20 selects a plurality of components (11, 12) from a plurality of component groups (A1, A2, A3, B1, B2, B3) with different characteristics, and uses th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com