Power module and vehicle having same

A technology for power modules and power chips, applied in the field of power modules and vehicles with them, can solve the problems of reducing the service life of power semiconductor modules, limited heat dissipation capacity of the bottom plate, different expansion coefficients, etc., and achieves simple structure, guaranteed electrical characteristics, production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

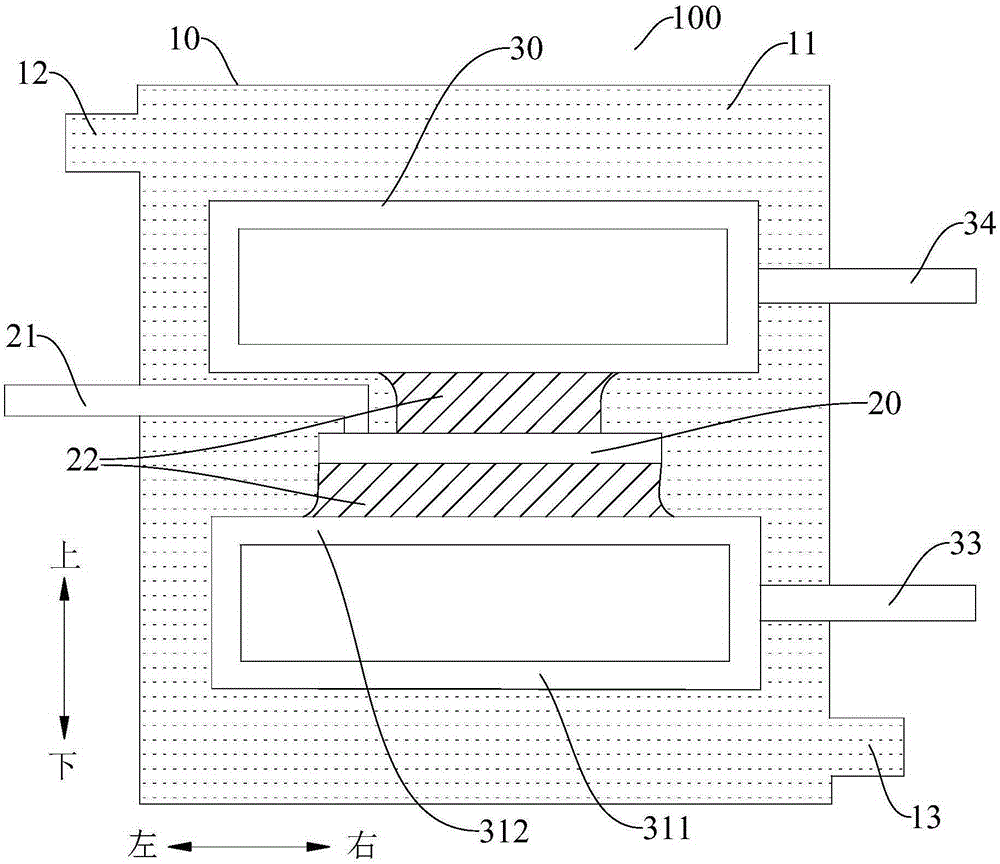

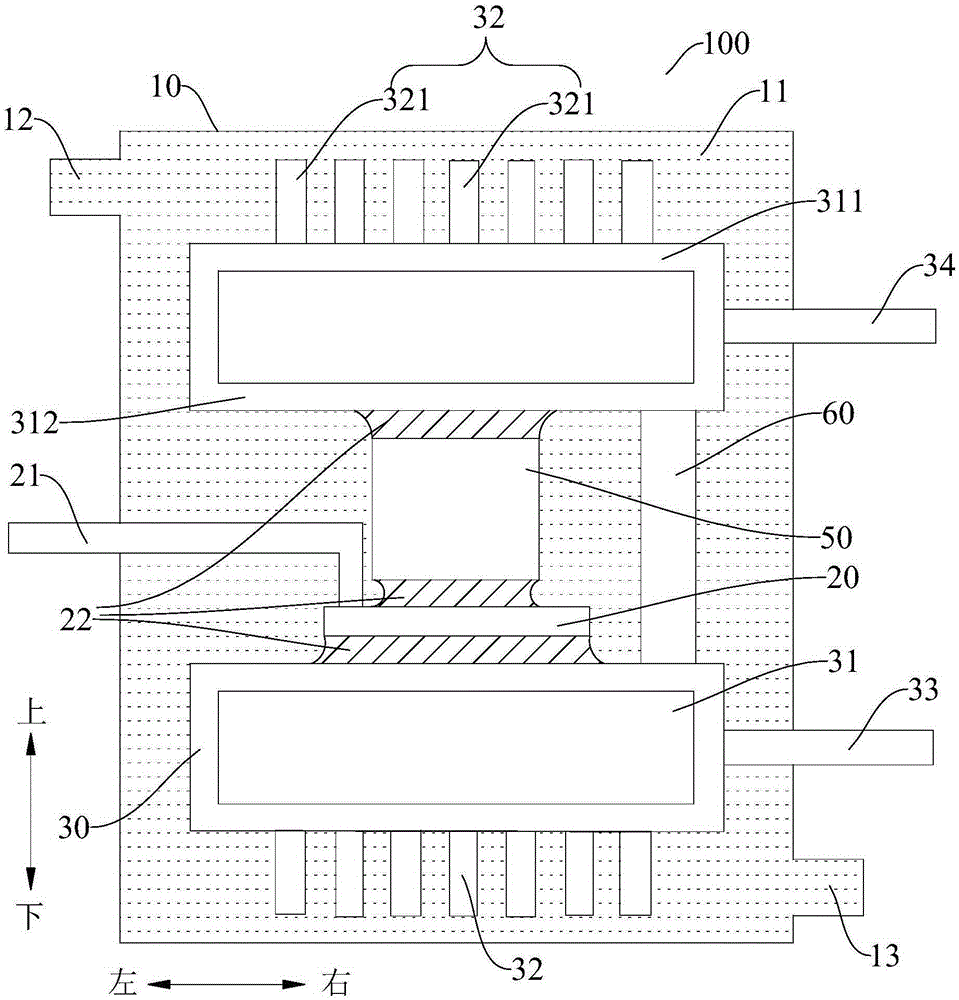

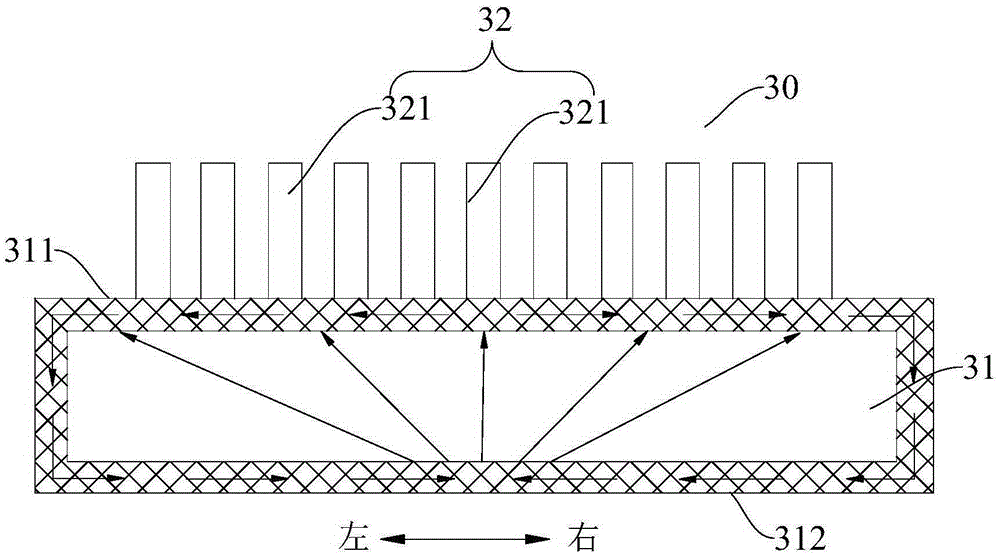

[0021] The following first combines the attached Figure 1 to Figure 3 The power module 100 according to the embodiment of the first aspect of the present invention will be described in detail.

[0022] Such as figure 1 As shown, the power module 100 according to the embodiment of the present invention includes a casing 10 , a power chip 20 and two flat heat pipes 30 . Specifically, the casing 10 defines an accommodation cavity 11, and the accommodation cavity 11 is filled with an insulating material (not shown). Covering, wherein, the insulating material can be a silicone material, or a cooling liquid with insulating and heat-conducting properties, so that it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com