Rigid-flex board and mobile phone camera module

A technology of soft and hard boards and hard boards, which is applied in image communication, television, color TV, etc., can solve the problems of poor imaging quality of image sensors, and achieve the effects of reducing poor imaging quality, reducing overheating, and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

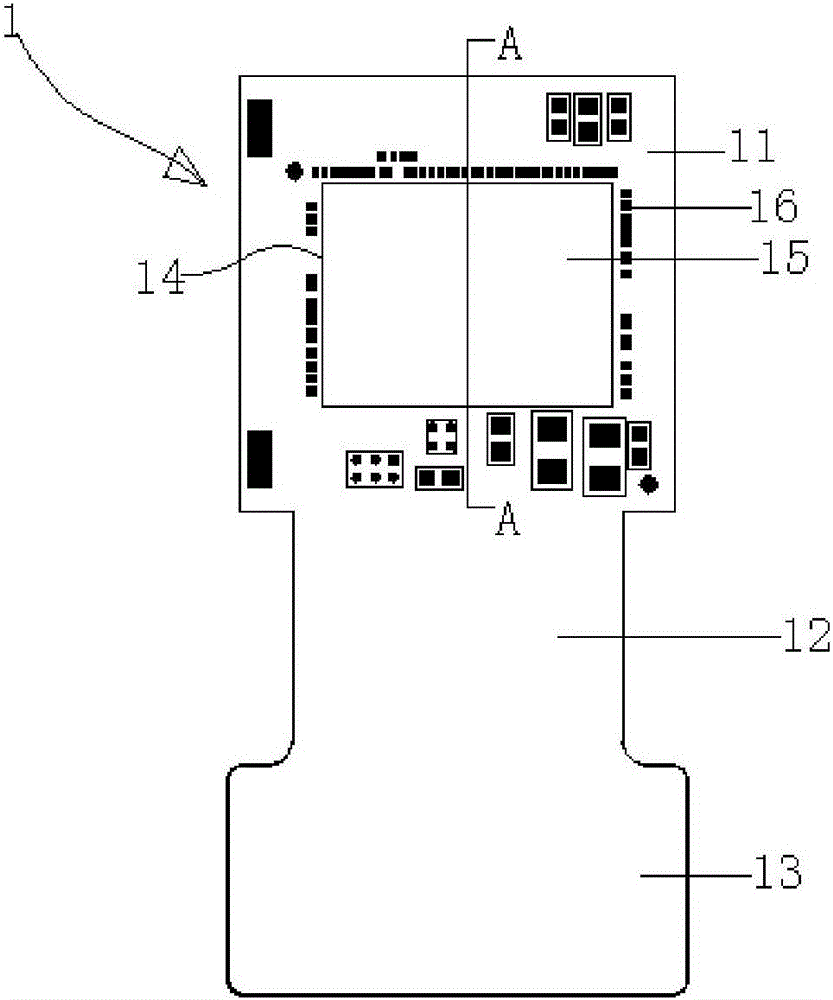

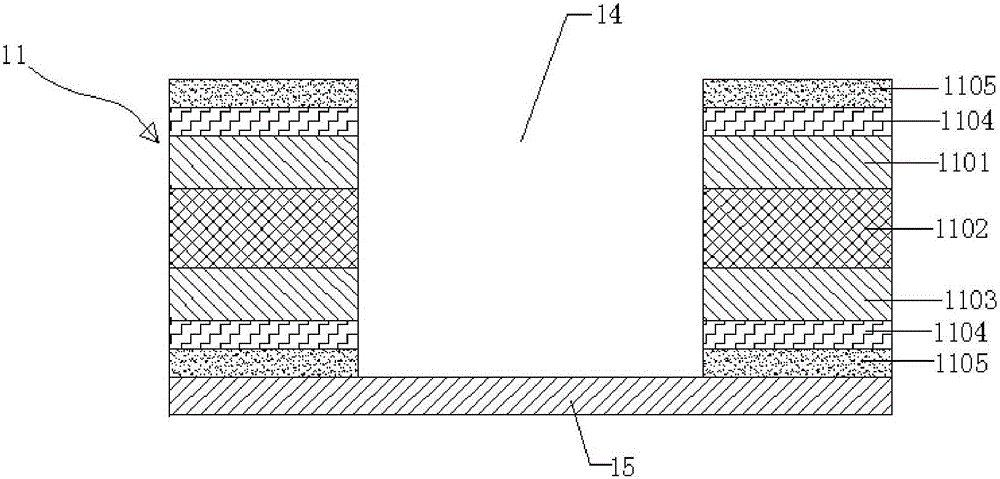

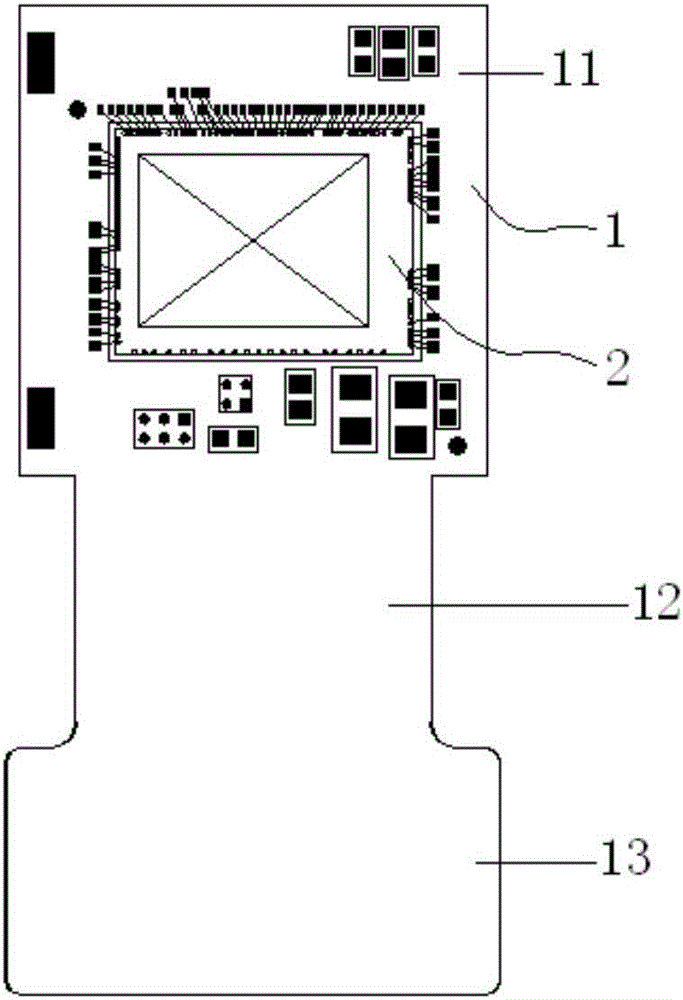

[0024] Such as figure 1 and figure 2 As shown, a rigid-flex board 1 includes a hard board part 11 for the lens, an intermediate soft board part 12 and a hard board part 13 for the connector. A sinking groove 14 is formed at the center of the hard board part of the lens to connect the lens The routing and via holes of the module 2 and the connector 3 are arranged around the sinking tank, and the back of the lens hard board is pasted with a reinforcing metal sheet 15 that closes the bottom opening of the sinking tank. During specific implementation, the position corresponding to the image sensor in the organic soft-hard combination board used on the conventional mobile phone camera module can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com