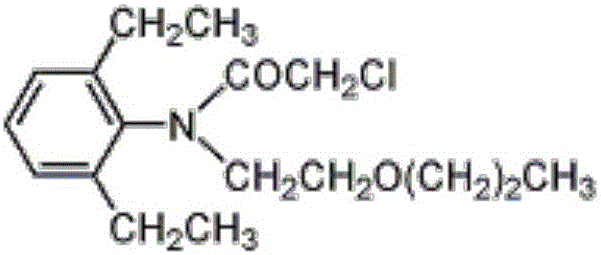

Micro-capsule suspending agent of pretilachlor and preparation method of micro-capsule suspending agent

A technology of microcapsule suspending agent and pretilachlor, applied in the field of pesticides, can solve the problems of poor weed effect, difficult storage, and difficulty in meeting the preparation requirements of weed control pesticides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

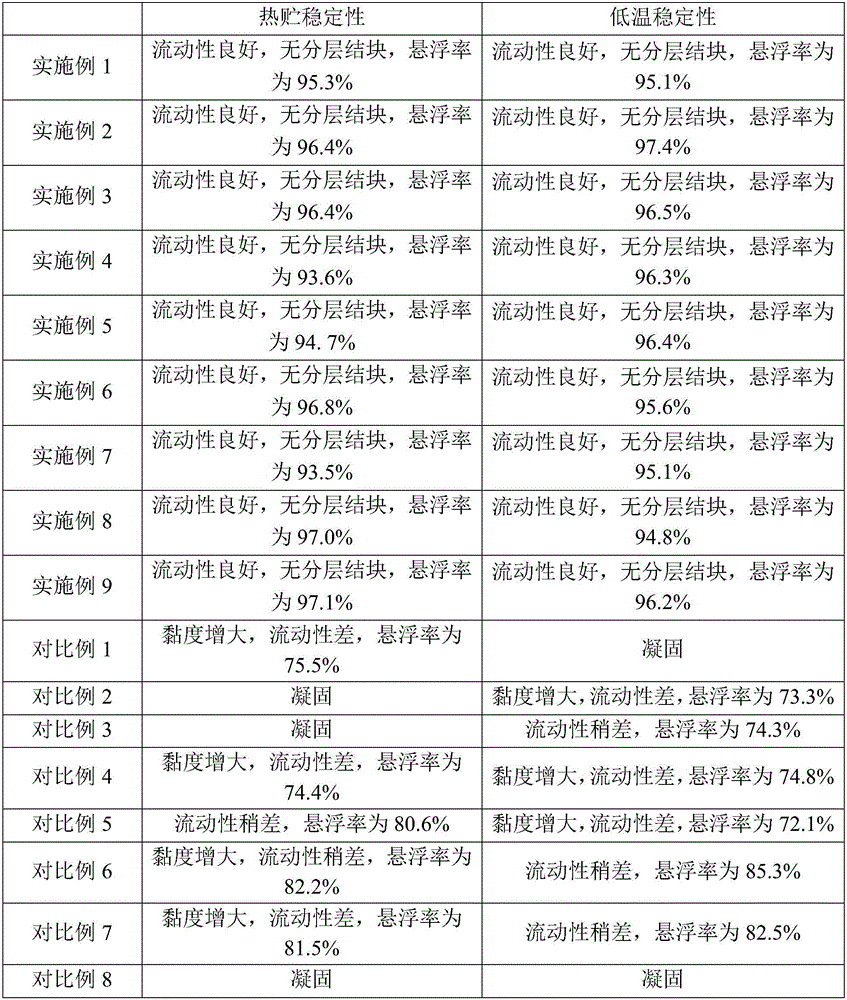

Examples

preparation example Construction

[0009] The present disclosure provides a preparation method of pretilachlor microcapsule suspension, which may include the following steps: (1) uniformly mixing the first solution and the second solution to obtain the first material; wherein, the first solution Contains melamine-formaldehyde resin prepolymer aqueous solution; the second solution contains pretilachlor emulsifiable concentrate; the weight ratio of the first solution to the second solution can be (1-4): 1; (2) the The first material is uniformly mixed with the buffer solution, and the pH value can be adjusted to 4-7 to obtain the second material; (3) the second material is uniformly mixed with the acidic pH value regulator, and the pH value can be adjusted to 3-4 , to obtain the third material; (4) carry out solidification and polycondensation of the third material to obtain a solidification polycondensation product, and the pH value of the solidification polycondensation product can be adjusted to 6.5-7.5; (5) th...

Embodiment 125

[0023] Example 1 25% pretilachlor microcapsule suspension

[0024] Mix melamine with a formaldehyde aqueous solution with a concentration of 37% by weight, and react for 1.5 hours at a pH of 8 and a temperature of 65° C.; add water to dilute to obtain a melamine-formaldehyde resin prepolymer aqueous solution, wherein the formaldehyde and melamine The molar ratio is 1:0.5, and the volume ratio of water and formaldehyde solution is 1:1.5.

[0025] Mix pretilachlor, 200# solvent oil and sorbitan monostearate polyoxyethylene ether to obtain pretilachlor emulsifiable concentrate, wherein, the pretilachlor and 200# solvent oil and sorbitan monostearate The weight ratio of stearate polyoxyethylene ether is 1:2.5:0.05.

[0026]Gained melamine-formaldehyde resin prepolymer aqueous solution and pretilachlor emulsifiable concentrate are mixed uniformly to obtain the first material, wherein the weight ratio of the melamine-formaldehyde resin prepolymer aqueous solution and pretilachlor e...

Embodiment 2

[0027] Example 2 25% pretilachlor microcapsule suspension

[0028] Melamine is uniformly mixed with formaldehyde aqueous solution having a concentration of 37% by weight, and reacted at a pH value of 8 and a temperature of 70°C; distilled water is added to dilute to obtain a melamine-formaldehyde resin prepolymer aqueous solution, wherein the molar amount of formaldehyde and melamine is The ratio is 1:0.5, and the volume ratio of water and formaldehyde solution is 1:2.

[0029] Mix pretilachlor, 200# solvent oil and sorbitan monostearate polyoxyethylene ether to obtain pretilachlor emulsifiable concentrate, wherein, the pretilachlor and 200# solvent oil and sorbitan monostearate The weight ratio of stearate polyoxyethylene ether is 1:2.5:0.05.

[0030] Gained melamine-formaldehyde resin prepolymer aqueous solution and pretilachlor emulsifiable concentrate are mixed uniformly to obtain the first material, wherein the weight ratio of the melamine-formaldehyde resin prepolymer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com