Spicy-flavored wire-drawing protein and producing method thereof

A technology of drawing protein and production method, which is applied in food mechanical processing, food drying, food forming, etc., can solve the problem of single taste, and achieve the effect of solving single taste and good fibrous tissue structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

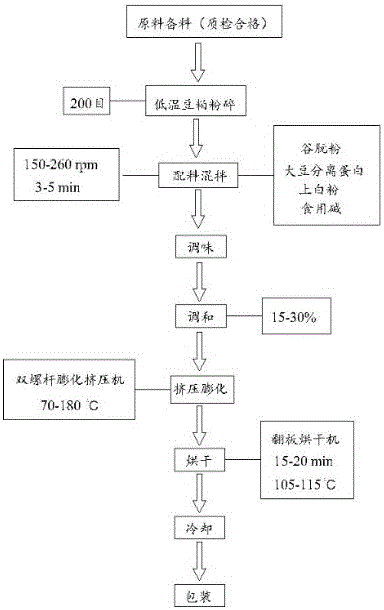

Method used

Image

Examples

Embodiment 1

[0022] A spicy-flavored silken protein, the spicy-flavored silken protein is composed of the following components in parts by weight, including 100 grams of low-temperature defatted soybean meal, 5-10 grams of gluten powder, 4-8 grams of soybean protein isolate, and 5-8 grams of white powder gram, 0.1 to 0.3 grams of edible alkali, 0.8 to 1.5 grams of compound seasoning, the compound seasoning is composed of the following components by weight, including 15 to 25 grams of chili powder, 1.5 to 3 grams of pepper powder, and 3 to 3 grams of onion powder 5 grams, 1.4-4.2 grams of white pepper powder, 4-8 grams of flaxseed powder, 0.8-1.5 grams of sea buckthorn powder, 2-3 grams of licorice powder, 0.5-1.5 grams of white sugar, the production method is as follows, the first step, raw materials Pulverize, put 100 grams of low-temperature defatted soybean meal through the pulverizer to 200 mesh, and input it into the hopper of the mixer; the second step, mix the ingredients, mix 5 to 1...

Embodiment 2

[0024] A spicy-flavored silken protein, said spicy-flavored silken protein is composed of the following components by weight, including 100 grams of low-temperature defatted soybean meal, 8 grams of gluten powder, 6 grams of soybean protein isolate, 6 grams of white powder, and 0.2 grams of edible alkali , 1.2 grams of compound seasoning, said compound seasoning is composed of the following components by weight, including 20 grams of chili powder, 2.4 grams of pepper powder, 4 grams of onion powder, 2.8 grams of white pepper powder, 6 grams of flaxseed powder, seabuckthorn Powder 1.1 grams, licorice powder 2.5 grams, white granulated sugar 1 gram, its production method is as follows, the first step, raw material is pulverized, and the low-temperature defatted soybean meal of 100 grams is pulverized to 200 orders, input mixer hopper; Second step, Mix the ingredients, put 8 grams of gluten powder, 6 grams of soybean protein isolate, 6 grams of white powder, and 0.2 grams of edibl...

Embodiment 3

[0026]A spicy-flavored silken protein, said spicy-flavored silken protein is composed of the following components in parts by weight, including 100 grams of low-temperature defatted soybean meal, 10 grams of gluten powder, 8 grams of soybean protein isolate, 8 grams of whitening powder, and 0.3 grams of edible alkali , 1.5 grams of compound seasoning, the compound seasoning is composed of the following components by weight, including 25 grams of chili powder, 3 grams of pepper powder, 5 grams of onion powder, 4.2 grams of white pepper powder, 8 grams of flaxseed powder, seabuckthorn Powder 1.5 grams, licorice powder 3 grams, white granulated sugar 1.5 grams, its production method is as follows, the first step, raw material is pulverized, and the low-temperature defatted soybean meal of 100 grams is through pulverizer to 200 orders, input mixer hopper; Second step, Mix the ingredients, put 10 grams of gluten powder, 8 grams of soybean protein isolate, 8 grams of whitening powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com