Mesophase pitch and method for preparing mesophase pitch by using coal liquefaction refined pitch

A technology for mesophase pitch and refined pitch, which is applied in the field of deep coal processing, can solve the problems of poor optical properties of mesophase pitch, influence the fusion of mesophase pitch, and maintain a short time in the liquid phase, so as to prolong the carbonization temperature range and reduce the System viscosity, the effect of improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The coal liquefaction refined pitch used in the following examples and comparative examples has the following characteristics: particle size≤5mm, quinoline insoluble content≤0.5wt%, softening point≥130°C.

[0041] Example 1

[0042] Fully mix 100g coal liquefaction refined pitch (provided by Shanghai Research Institute of China Shenhua Coal-to-oil Chemical Co., Ltd.) with 100g coking heavy oil (provided by Shanghai Baosteel Chemical Co., Ltd.), then place the mixture in a 500ml autoclave, seal it Purging with nitrogen to make the nitrogen pressure reach 0.5MPa, the mixture is heated up to 200°C at 20°C / min, and then gradually raised to 440°C at a rate of 1°C / min, and kept at constant temperature and pressure for 8 hours to obtain mesophase pitch .

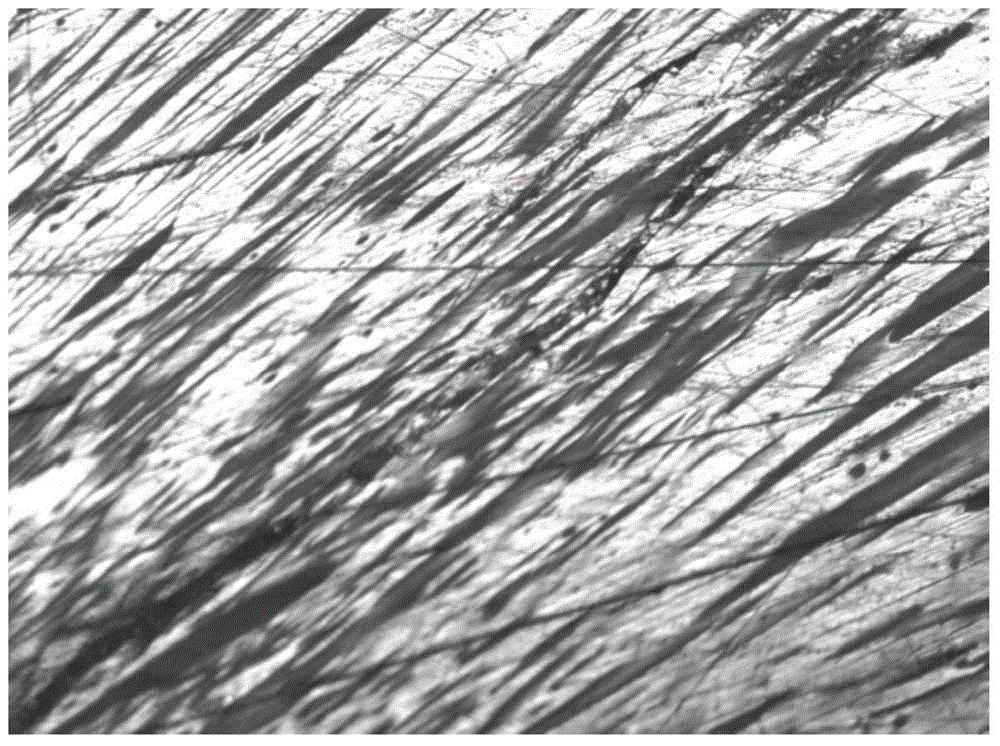

[0043] The mesophase pitch prepared in Example 1 is observed under a polarizing microscope, and the polarizing microscope photo is shown in figure 1 . From figure 1 It can be seen that the mesophase pitch has a fibrous s...

Embodiment 2

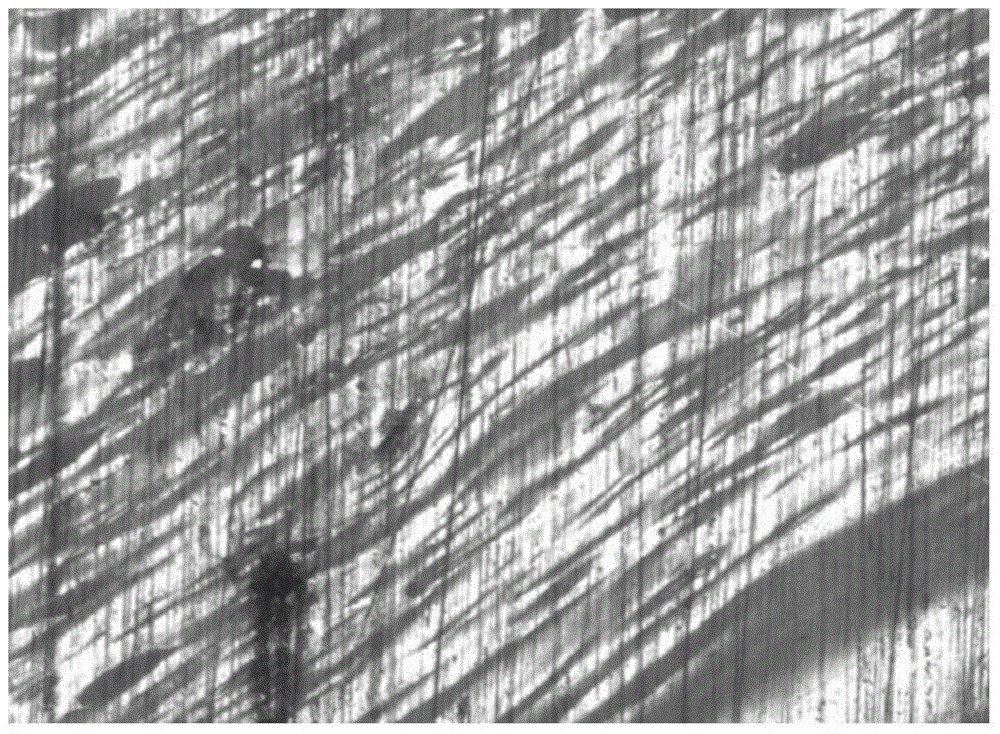

[0049] 150g coal liquefaction refined pitch (provided by Shanghai Research Institute of China Shenhua Coal Oil Chemical Co., Ltd.) and 50g anthracene oil (provided by Maanshan Steel Co., Ltd.) are fully mixed, then the mixture is placed in a 500ml autoclave, and after sealing Purging with nitrogen to make the nitrogen pressure reach 5MPa, the temperature of the mixture was raised to 200°C at 16°C / min, and then gradually raised to 400°C at a rate of 2.0°C / min, and kept at constant temperature and pressure for 16 hours to obtain fibrous structure. Mesophase pitch, its polarized light microscope photo is shown in image 3 .

Embodiment 3

[0051] Fully mix 125g coal liquefaction refined pitch (provided by Shanghai Research Institute of China Shenhua Coal-to-oil Chemical Co., Ltd.) with 75g coking heavy oil (provided by Shanghai Baosteel Chemical Co., Ltd.), then place the mixture in a 500ml autoclave, seal it Purging with nitrogen to make the nitrogen pressure reach 2.0MPa, the mixture is heated up to 200°C at a rate of 10°C / min, then gradually raised to 420°C at a rate of 3.0°C / min, and kept for 10 hours to obtain a fibrous structure mesophase Asphalt, the polarizing microscope photo of the mesophase pitch is shown in Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com