Multi-degree of freedom forklift for metal surface treatment

A technology for metal surface treatment and degree of freedom, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as non-stop, consuming a lot of manpower and material resources, affecting welding quality, etc., to improve automation. horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

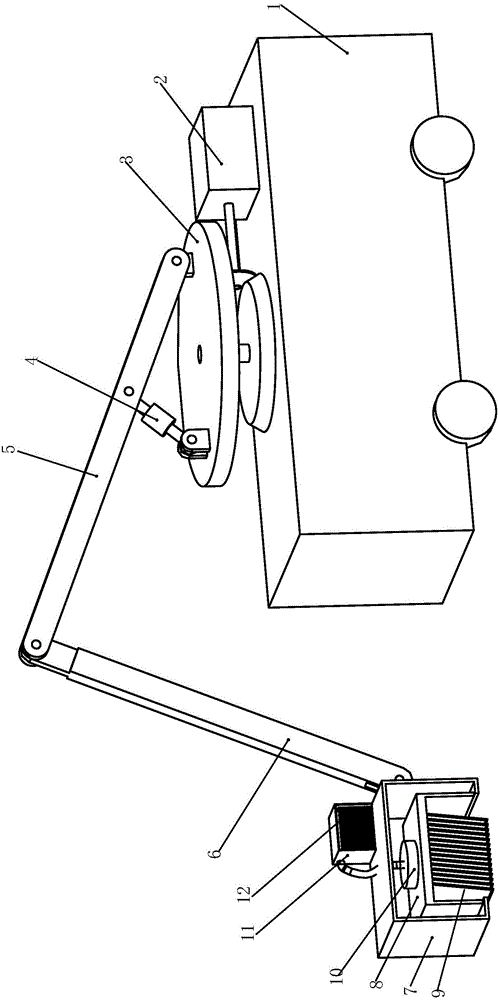

[0015] Such as figure 1 Shown, a kind of multi-degree-of-freedom forklift for metal surface treatment includes a mobile vehicle 1, a motor 2 is installed on the top of the mobile vehicle 1, and a driving wheel is installed on the shaft of the motor 2, and the driving wheel is installed with the The driven wheel on the mobile vehicle 1 is meshed, and the upper part of the driven wheel is fixedly connected with a turntable 3. The left side of the turntable 3 is connected with a hydraulic cylinder 4 through a hinged manner, and the right side of the turntable 3 is connected with a lifting arm 5 through a hinged manner. , the other end of the hydraulic cylinder 4 is hingedly connected to the middle of the lifting arm 5, the other end of the lifting arm 5 is hingedly connected to a push rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com