High-position push-type self-unloading device for rubber-tyred vehicles

A self-unloading device and rubber-tyred vehicle technology, which is applied in the direction of lifting devices, fluid pressure actuating devices, servo motors, etc., can solve the problems of inability to realize the backward translation of the cargo compartment and limited distance, and achieve simple structure, convenient operation, strong support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] With reference to the drawings, the specific implementation of the present invention will be further explained:

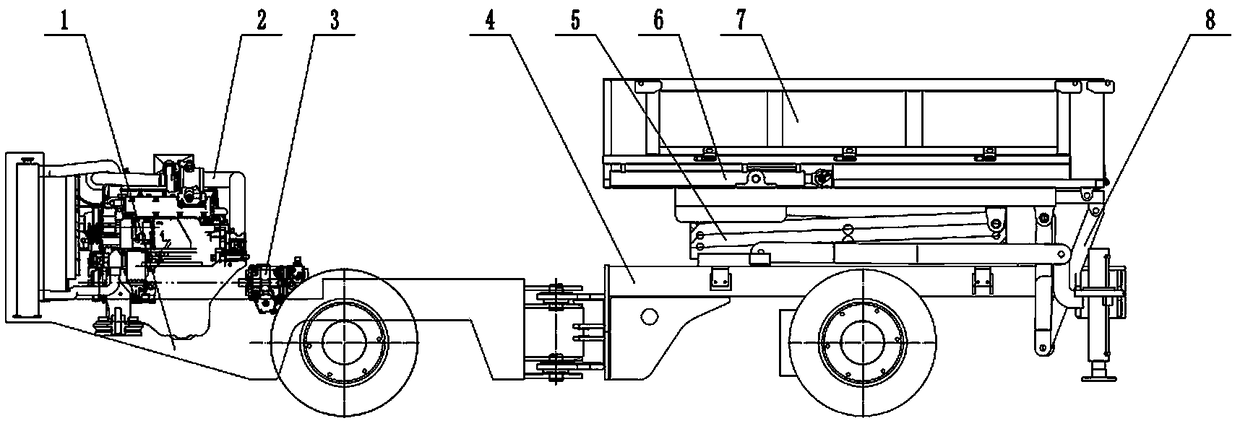

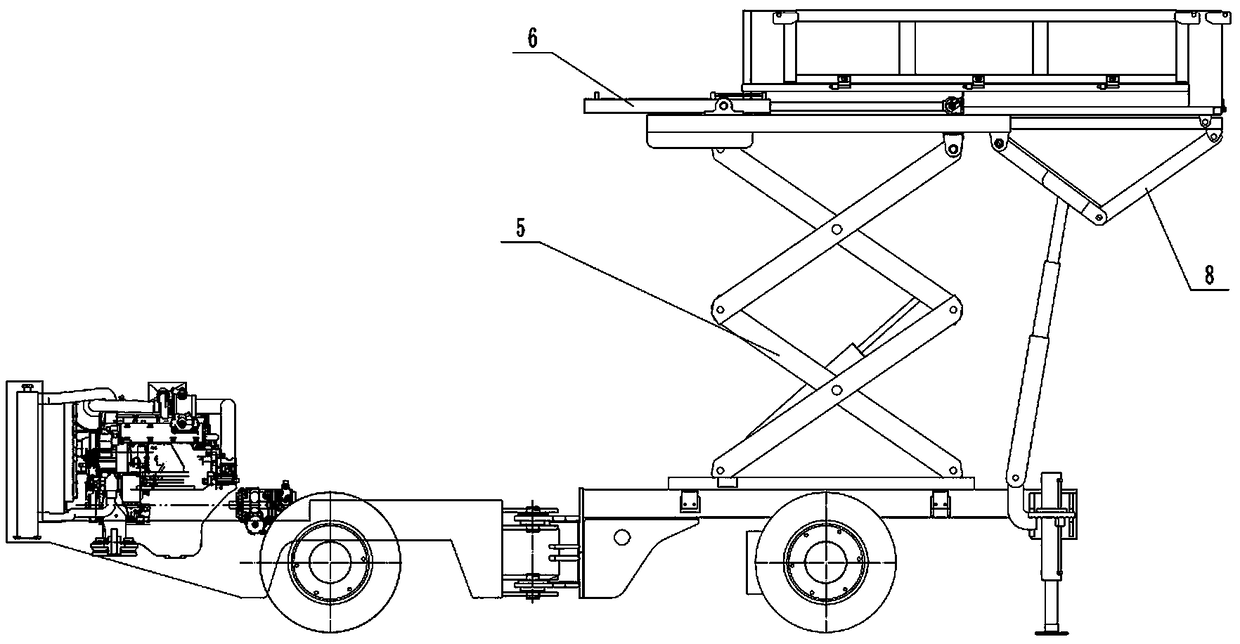

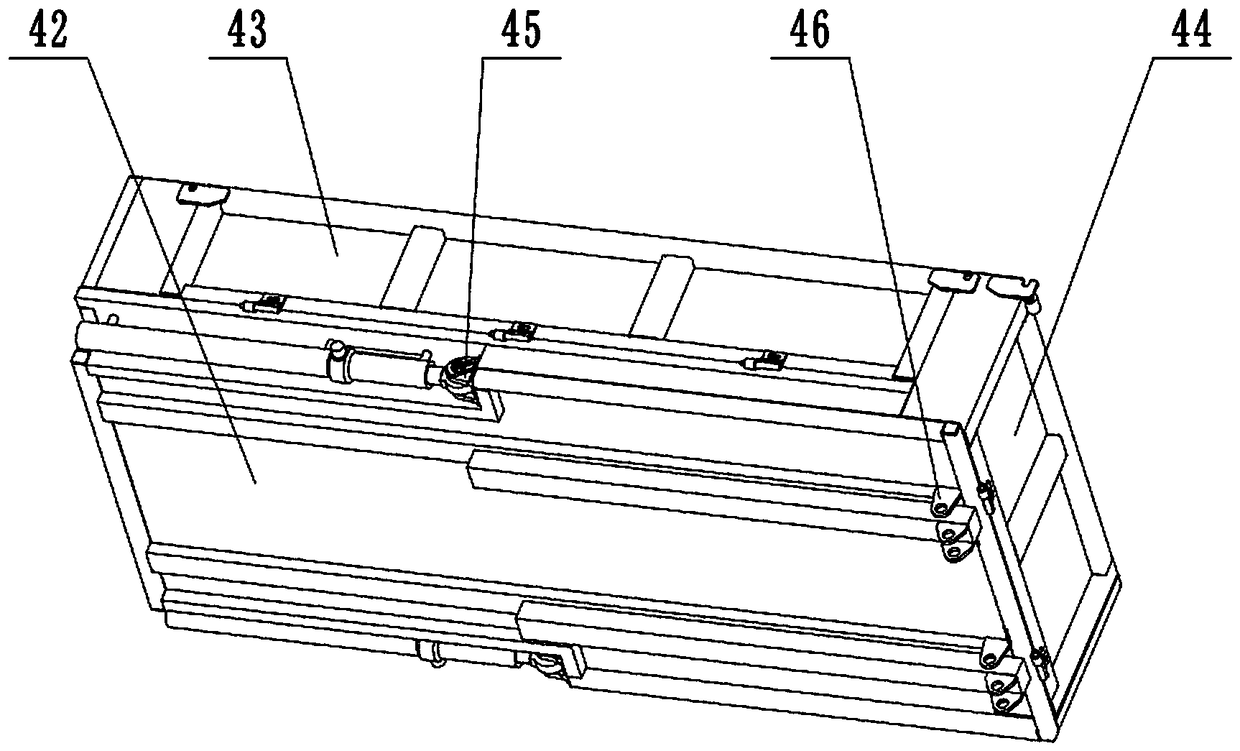

[0036] Such as figure 1 , figure 2 Shown is a high-position sliding dump device for a rubber-tyred vehicle, including a front frame 1, a diesel engine 2, a hydraulic oil pump 3, a rear frame 4, a lifting mechanism 5, a telescopic cylinder 6, a sliding cargo compartment 7 and a support Rod assembly 8; the upper part of the front frame 1 is connected to the diesel engine 2, and the rear part of the diesel engine 2 is connected to the hydraulic oil pump 3. The diesel engine 2 and the hydraulic oil pump 3 form a power unit. The front frame 1 and the rear frame 4 are hinged, and the rear car The upper part of the frame 4 is connected to the lifting mechanism 5, the upper part of the lifting mechanism 5 is connected to the sliding cargo box 7 through the telescopic cylinder 6, and the sliding cargo box 7 is connected to the lifting mechanism 5 and the rear frame 4 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com