Method for selecting particle size distribution ranges and filling amount ratio of heat-conducting silica gel thermal interface material powder filler

A technology of thermal interface material and powder filler, applied in the field of thermally conductive silica gel thermal interface material, can solve the problems of low thermal conductivity and non-dense powder particles, and achieve an increase in bulk density, a reduction in porosity, and a strong theoretical guidance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

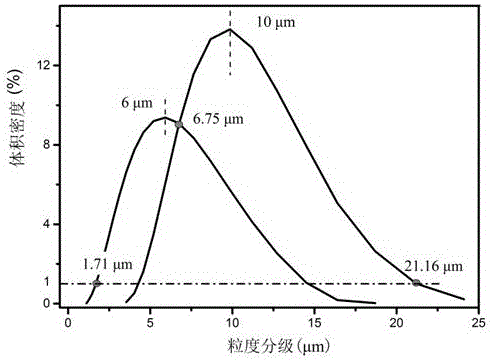

[0034] Embodiment 1: Select two kinds of thermally conductive powder fillers with different particle size distribution ranges, and use two different particle size distribution ranges of 10 μm and 6 μm (such as figure 1 ) aluminum powder filler for multi-scale compounding, using the Dinger-Funk closest packing equation to calculate the volume percentage of aluminum powders with two different particle sizes when compounding, the process is as follows:

[0035] First, determine the distribution range of the particle size of the thermally conductive powder filler: the distribution range of the 6 μm particle size is [1.71, 6.75], and the distribution range of the 10 μm particle size is [6.75, 21.16].

[0036] Then, the Dinger-Funk closest packing equation: Among them, in the composite heat-conducting powder filler system D max =21.16,D min =1.71, n=0.37, U(D p ) value by D p Get the value, as shown in the following table:

[0037]

[0038]

[0039] Therefore, it is conclu...

Embodiment 2

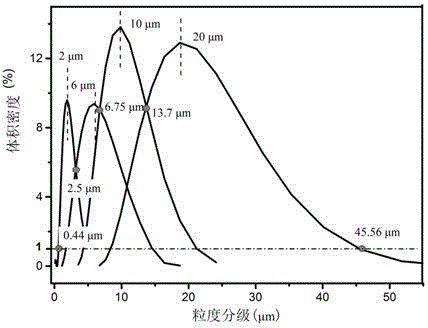

[0049] Embodiment 2: Select four kinds of thermally conductive powder fillers with different particle size distribution ranges, and four different particle size distribution ranges of 20 μm, 10 μm, 6 μm and 2 μm (such as figure 2 ) for multi-scale compounding of aluminum powder fillers, using the Dinger-Funk closest packing equation to calculate the volume percentage of aluminum powder fillers with four different particle sizes when compounding, the process is as follows:

[0050] First, determine the distribution range of the particle size of the thermally conductive powder filler: the distribution range of the 2μm particle size is [0.44,2.5], the distribution range of the 6μm particle size is [2.5,6.75], and the distribution range of the 10μm particle size is [6.75,13.7], the distribution range of 20μm particle size is [13.7,45.56].

[0051] Then, the Dinger-Funk closest packing equation: Among them, in the composite heat-conducting powder filler system D max =45.56,D m...

Embodiment 3

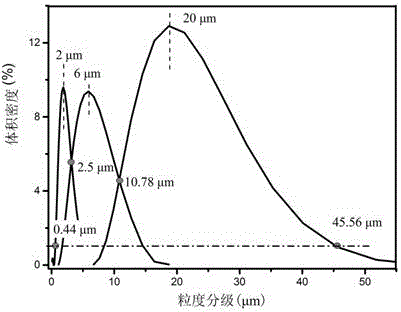

[0062] Three thermally conductive powder fillers with different particle size distribution ranges are selected, and three different particle size distribution ranges of 20 μm, 6 μm and 2 μm (such as image 3 ) aluminum powder fillers for multi-scale compounding, using the Dinger-Funk closest packing equation to calculate the volume percentage of aluminum powder fillers with three different particle sizes when compounding, the process is as follows:

[0063] First, determine the distribution range of the particle size of the thermally conductive powder filler: the distribution range of the 2μm particle size is [0.44,2.5], the distribution range of the 6μm particle size is [2.5,10.78], and the distribution range of the 20μm particle size is [10.78, 45.56].

[0064] Then, the Dinger-Funk closest packing equation: Among them, in the composite heat-conducting powder filler system D max =45.56,D min =0.44, n=0.37, U(D p ) value by D p The value is obtained, as shown in the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com