A foil machine power supply integration structure and copper foil production equipment

A technology of production equipment and raw foil machine, applied in electroforming, electrolysis process and other directions, can solve the problems of loose equipment structure, large space occupation, heavy power supply weight, etc., to achieve compact structure, small space occupation, saving conductive busbars. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

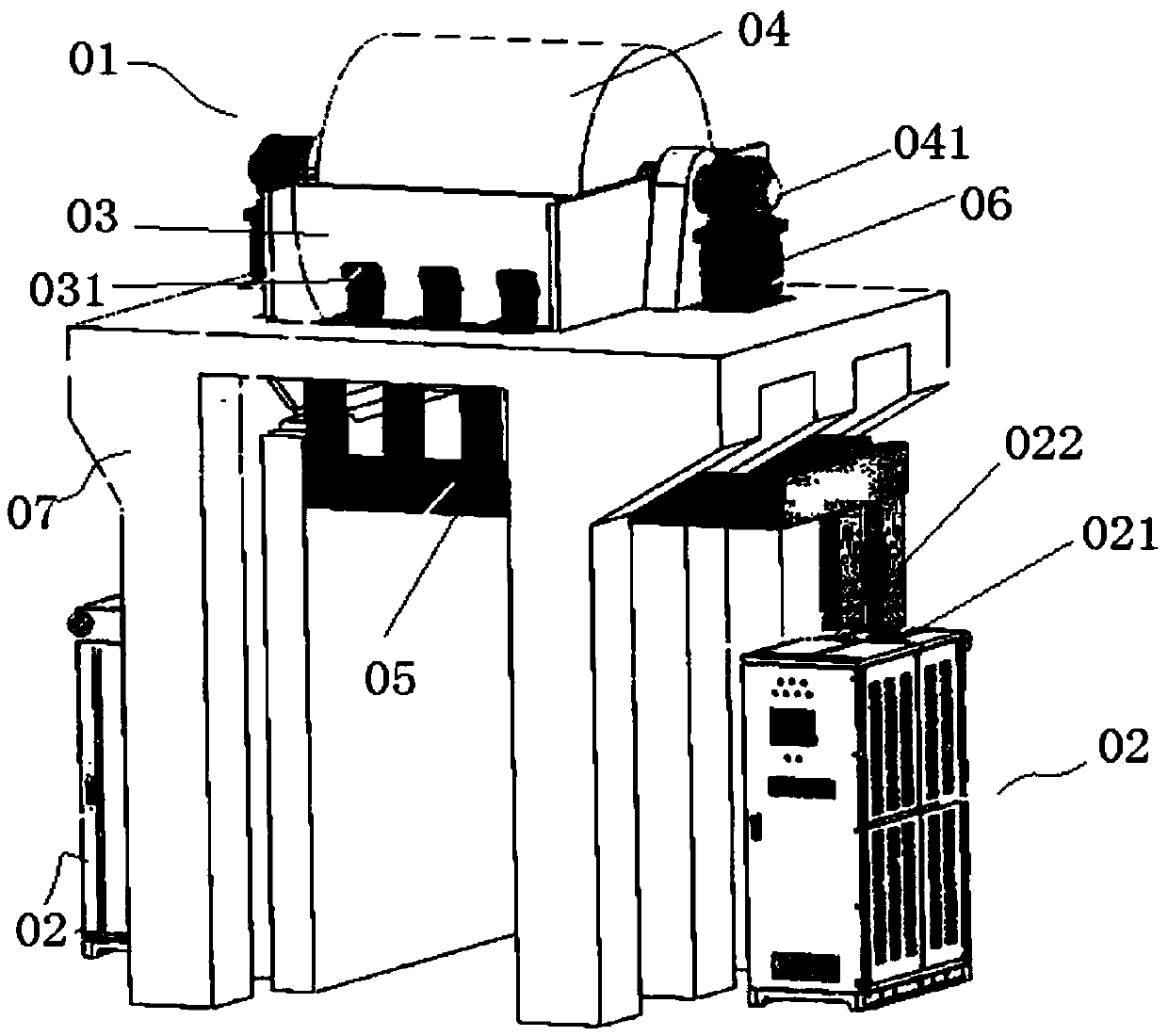

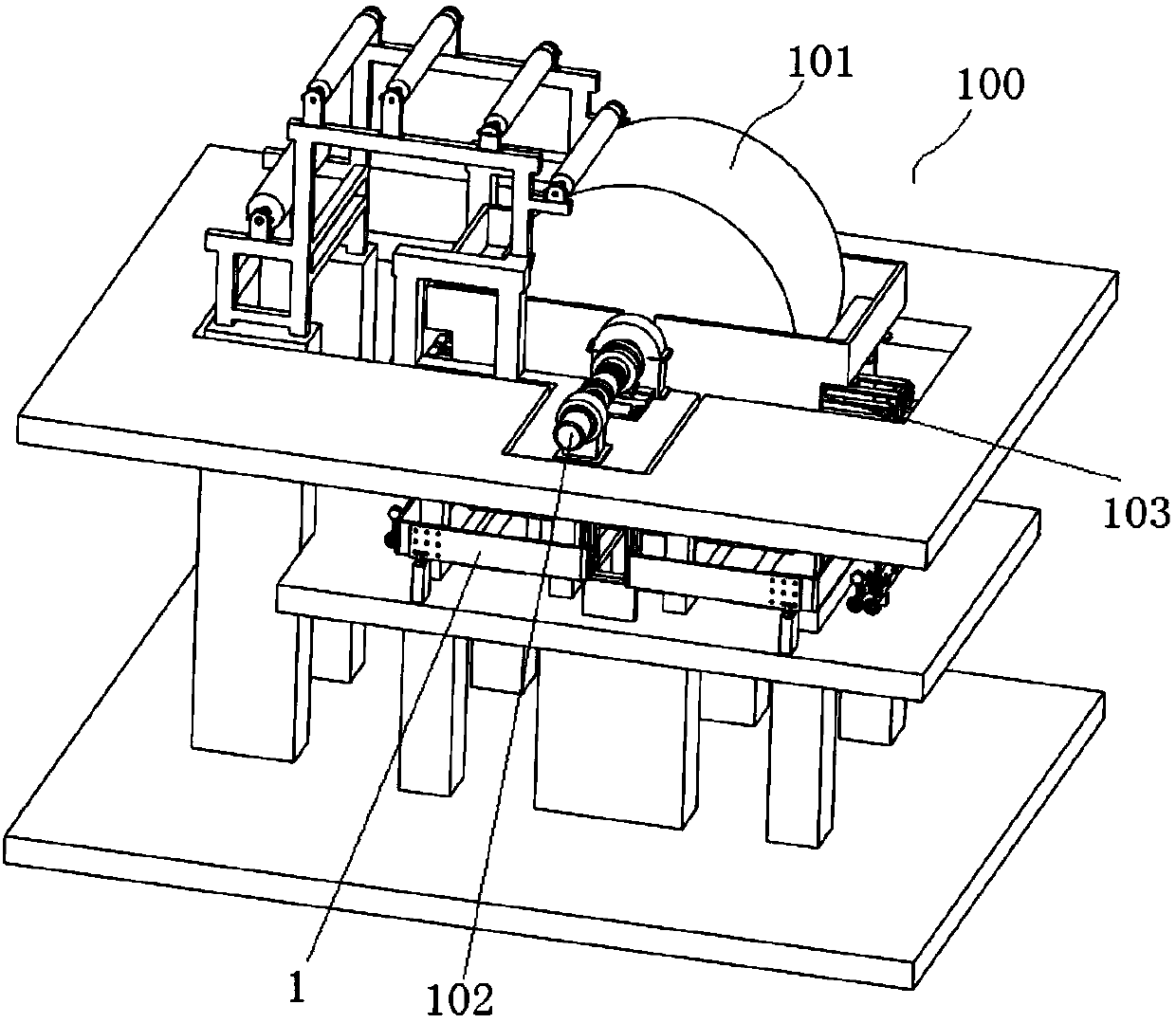

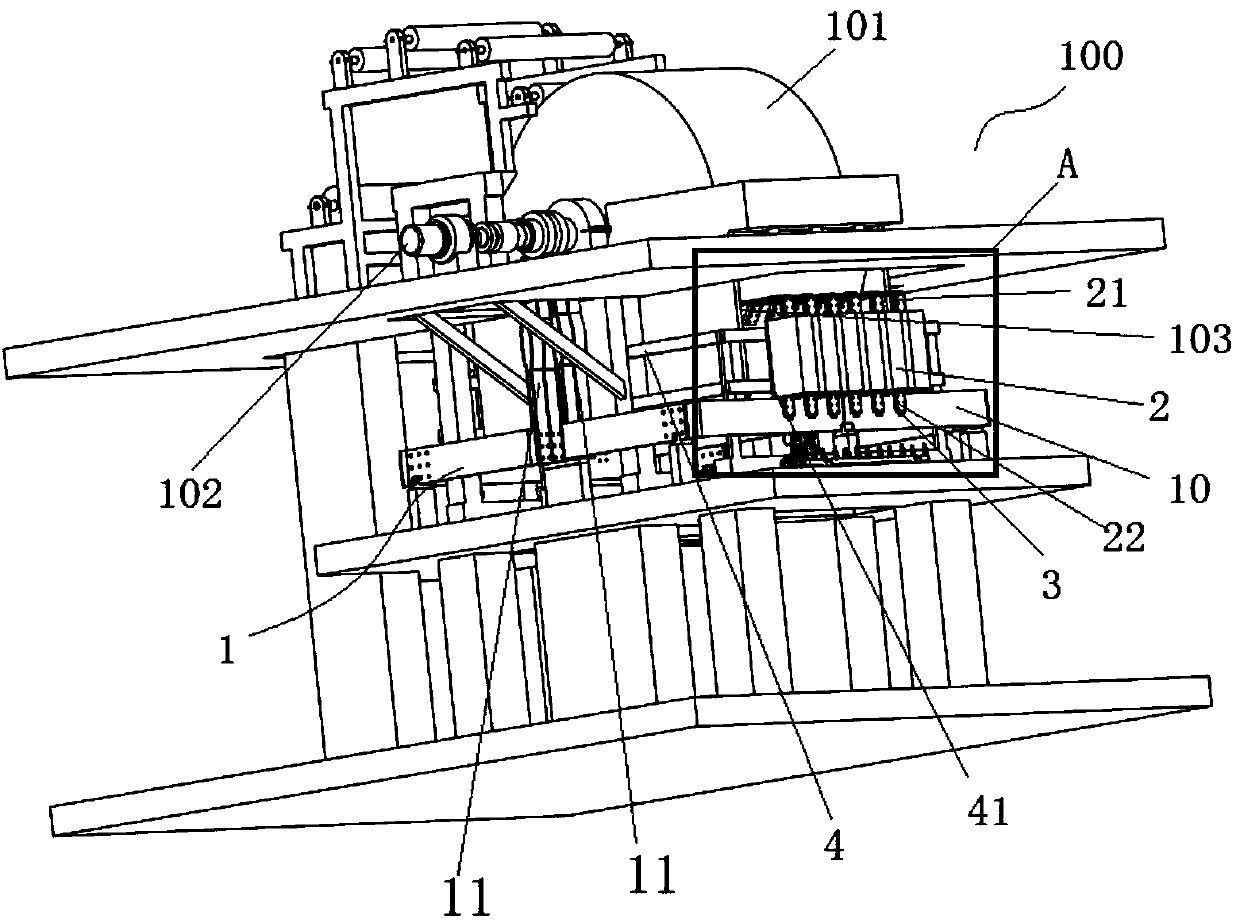

[0060] This embodiment provides an integrated structure of the power supply of the foil machine, such as Figure 2-4 As shown, there are two conductive bus bars 1, each conductive bus bar 1 is electrically connected to the two conductive columns 102 of the cathode roller 101 on the foil machine 100, and has a power connection section 10 , the power connection section 10 extends to a position corresponding to one of the anode plates 103, thereby forming an installation space between the power connection section 10 and the anode plate 103, and the installation space is suitable for installing at least one (there are 6 in this embodiment) power supply module 2 .

[0061] In the integrated structure of this embodiment, the conductive bus bar 1 has a power supply connection section 10, and the power supply connection section 10 is opposite to the anode plate 103 to form an installation space for installing the power supply module 2. Since the power supply module 2 is small in size,...

Embodiment 2

[0071] This implementation provides an integrated structure of the power supply of the foil machine, which is a deformation on the basis of Example 1. The difference is that in this embodiment, there is one conductive busbar, which is suitable for connecting with the two conductive busbars of the cathode roller on the foil machine. The column is electrically connected, and has two power supply connection sections, and the two power supply connection sections are respectively adapted to correspond to the two anode plates of the foil producing machine, thereby forming two installation spaces suitable for installing at least one power supply module.

Embodiment 3

[0073] This embodiment provides a copper foil production equipment, such as Figure 2-4 As shown, it is installed on a concrete structure, including: a foil machine 100, which has a cathode roller 101 and an anode plate 103, and the outer peripheral surface of the cathode roller 101 is opposite to the anode plate 103 to form a solution space; a conductive busbar 1, Each conductive bus bar 1 is electrically connected to two conductive columns 102 of the cathode roller 101, and has a power connection section 10, which extends to a position corresponding to one of the anode plates 103, so that An installation space is formed between the power connection section 10 and the anode plate 103; at least one power supply module 2 (six in this embodiment) is installed in the installation space, and the anode end 21 is connected to the anode plate 103 is electrically connected, and the cathode terminal 22 is electrically connected to the power connection section 10 .

[0074] In the copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com