Method for fixing blades of wind blade spoke-type wind wheel electricity generation device, device and electricity generation device

A technology of a power generation device and a fixing method is applied in the field of a wind impeller-spoke type wind turbine power generation device and a planetary gear eccentric lever-driven energy-saving gearbox, which can solve the problems of difficult market-oriented operation of wind power energy, low wind energy efficiency, and poor power generation efficiency. Achieve the effect of stable and reliable power generation quality, large installed capacity and large torsional force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

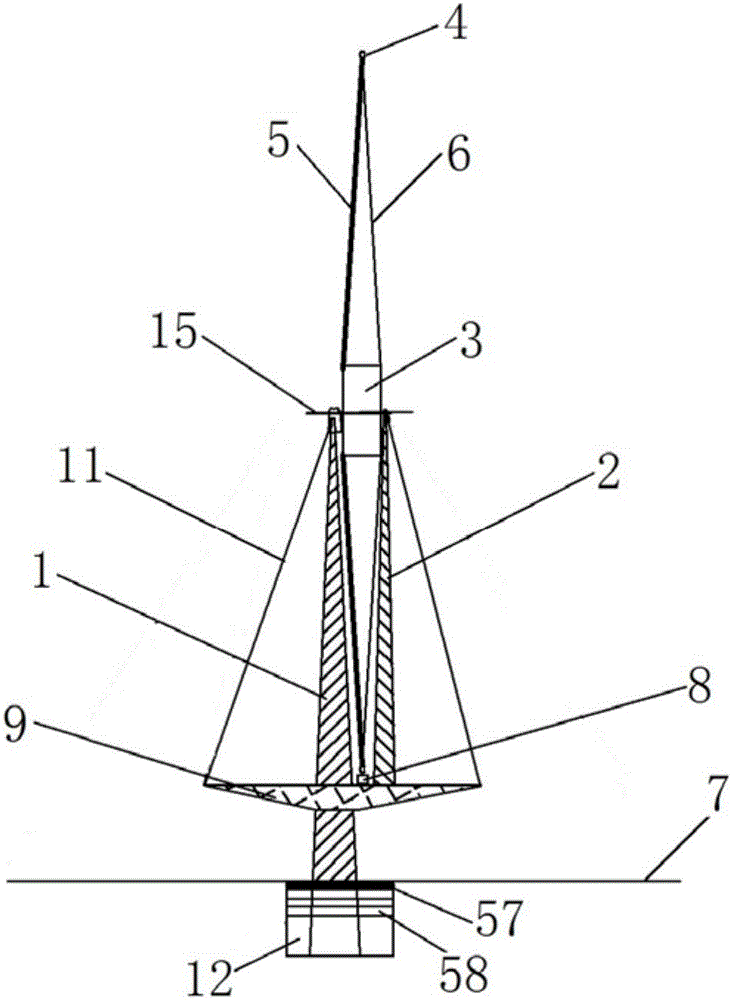

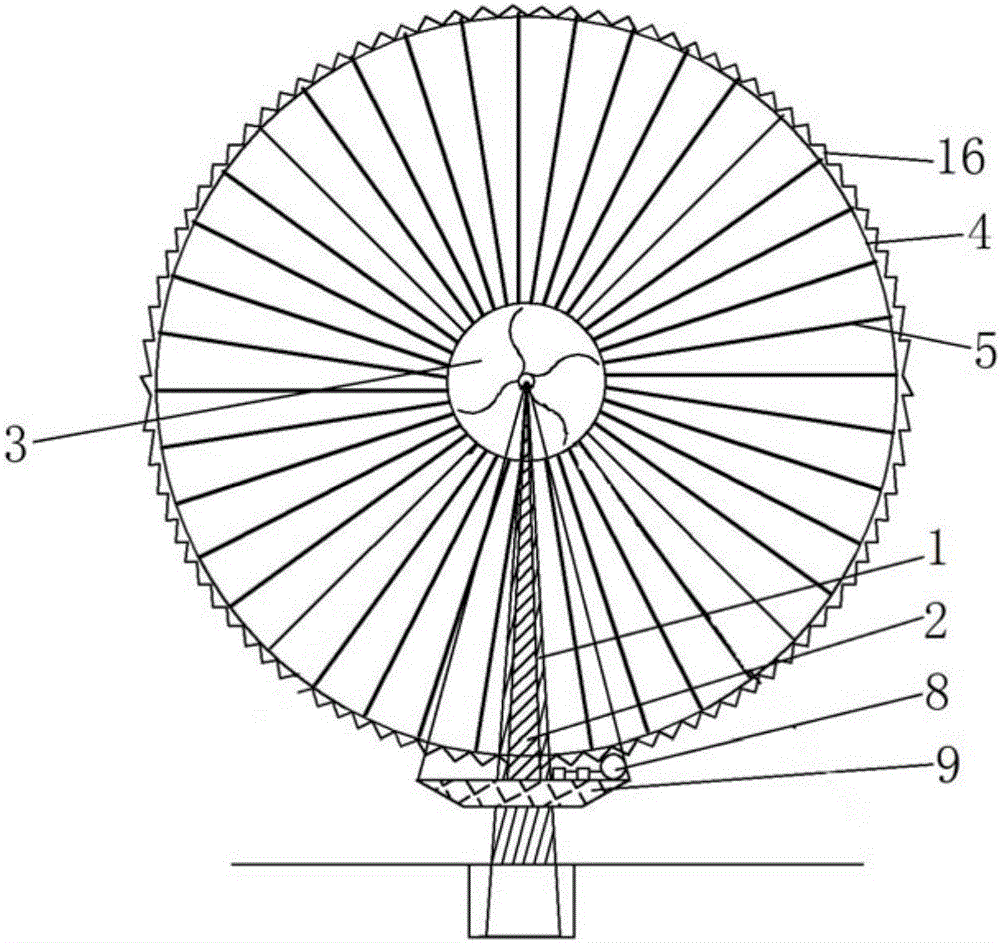

[0049] like figure 1 and 2 Shown is a schematic structural view of the wind turbine power generation device of Embodiment 1. The wind turbine generating device includes: a tower column, a wind rotor, a driven wheel, a planetary gear eccentric drive gearbox, multiple generators and a steering system.

[0050] The wind wheel includes a central hub 3 , an outer rim 4 , several blades 5 and several first stay cables 6 .

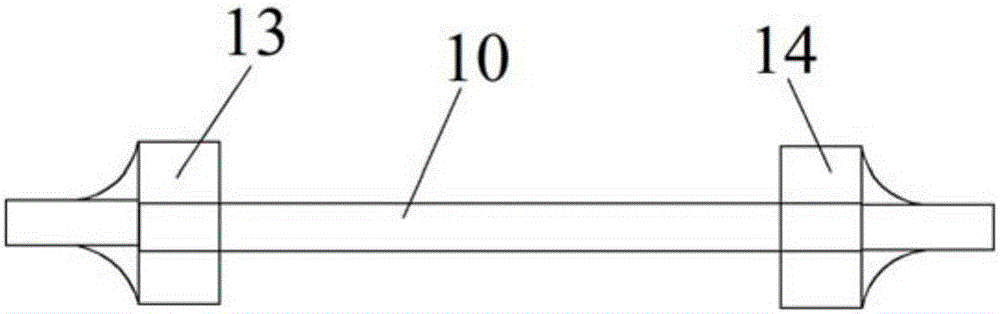

[0051] like image 3 As shown, the central hub 3 includes a shaft cylinder 10 and two ends of the hubs. The two ends of the hubs are a first hub 13 and a second hub 14 . One end of each blade 5 is fixed on the first hub 13 , and the other end is fixed on the outer rim 4 ; one end of each first stay cable 6 is fixed on the second hub 14 , and the other end is fixed on the outer rim 4 .

[0052] The tower system includes a main tower 1 , an auxiliary tower 2 and a first steering platform support frame 9 . The main tower column 1 is fixed on the ground using a ...

Embodiment 2

[0072] like Image 6 Shown is a schematic structural view of the wind turbine power generation device of Embodiment 2. It is different from the structure of Example 1. The central hub includes a shaft cylinder, two ends of the hub and a middle hub 60. The two ends of the hub are the first hub and the second hub. the central segment. One end of each blade 5 is fixed on the middle hub 60, and the other end is fixed on the outer rim 4, and the blade 5 is in a vertical state. One end of each first stay cable 6 is fixed on the first hub or the second hub, and the other end is fixed on the outer rim 4 .

[0073] In Embodiment 2, the tower system includes a fixed tower shaft 22 , a second steering platform support frame 20 , a front tower column 21 and a rear tower column 62 . The fixed tower shaft 22 is arranged on the ground 7 . The second steering platform support frame 20 is rotatably arranged on the fixed tower shaft 22 . The front tower column 21 and the rear tower column...

Embodiment 3

[0076] like Figure 7 and 8 As shown, it is a structural schematic diagram of different fixing methods of the blade of the present invention.

[0077] Figure 7 Among them, one end of the blade 5 is fixed on the hub of the middle section, and the other end is fixed on the outer rim 4 via the fourth stay cable 24 . In the middle of the blade 5 , it is fixed at the first fixed point 27 of the blade through the fifth stay cable 26 , and is fixed at the second fix point 29 of the blade through the sixth stay cable 28 . The other ends of the fourth stay cable 24 , the fifth stay cable 26 and the sixth stay cable 28 are respectively fixed on the hubs at both ends. In addition, there are front and rear support rods 23 between the fourth stay cables 24 , and the two ends of the front and rear stay stay rods 23 are cross-fixed on the hubs at both ends via the seventh stay cables 30 and the eighth stay cables 31 .

[0078] Figure 8 Among them, one end of the blade 5 is fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com