Switch withstand voltage detection system and detection method

A technology for withstand voltage detection and switches, which is applied in the direction of testing dielectric strength, etc., can solve the problem that the withstand voltage detection method cannot comprehensively detect the withstand voltage performance of the whole switch system, cannot better explore system compatibility problems, and affect products Develop quality and quality requirements and other issues to achieve the effect of convenient and fast detection, strong applicability and practicability, and convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

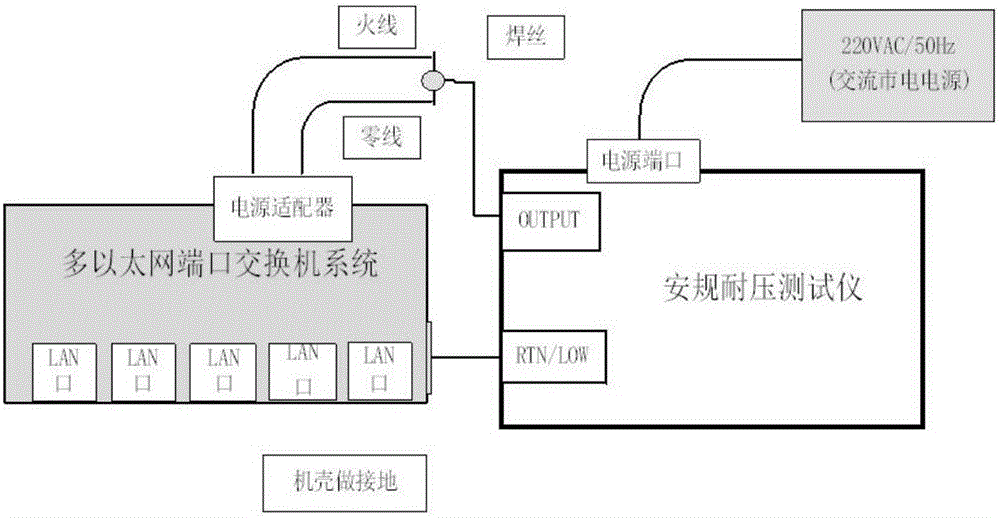

Embodiment 1

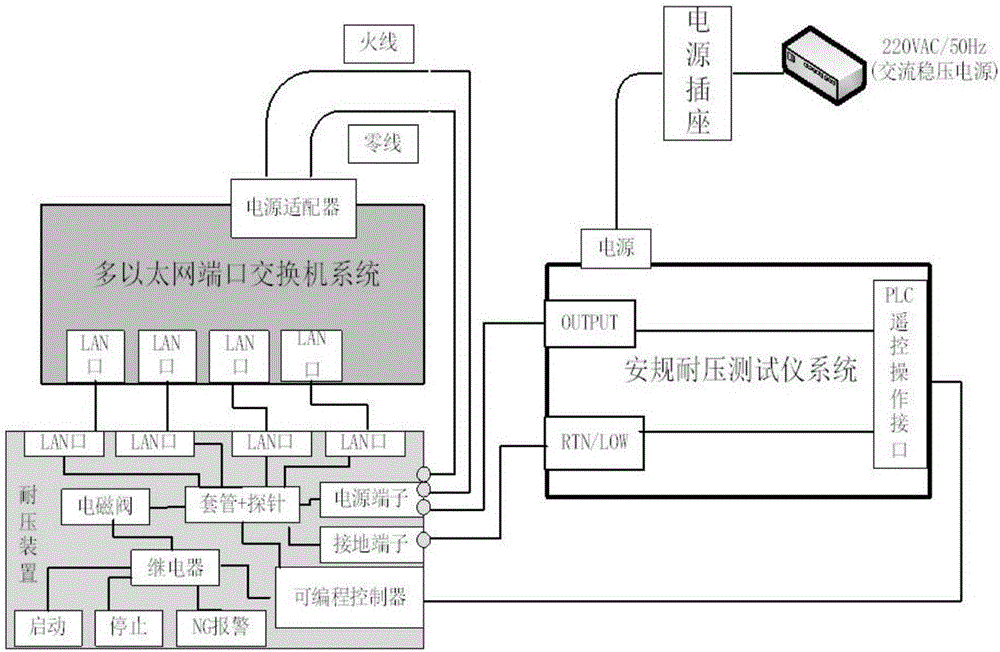

[0040] Such as figure 2 As shown, the withstand voltage detection system of the switch in this embodiment includes a withstand voltage tester and a withstand voltage detection part. The withstand voltage tester is mainly composed of a power port, a voltage regulator, a logic control module, an indication module, an output terminal, and a feedback It consists of terminals and PLC remote operation interface. The power port is externally connected to a power socket equipped with an AC regulated power supply, and the voltage regulator is adjusted so that the withstand voltage tester can adjust to the required test voltage through the high-voltage circuit and the boost circuit and output it through the output terminal. The display indicator module is used to display the change of the voltage, intuitively display the current voltage value through the electronic display screen, and is used to judge whether the test voltage meets the requirements, the withstand voltage capability of ...

Embodiment 2

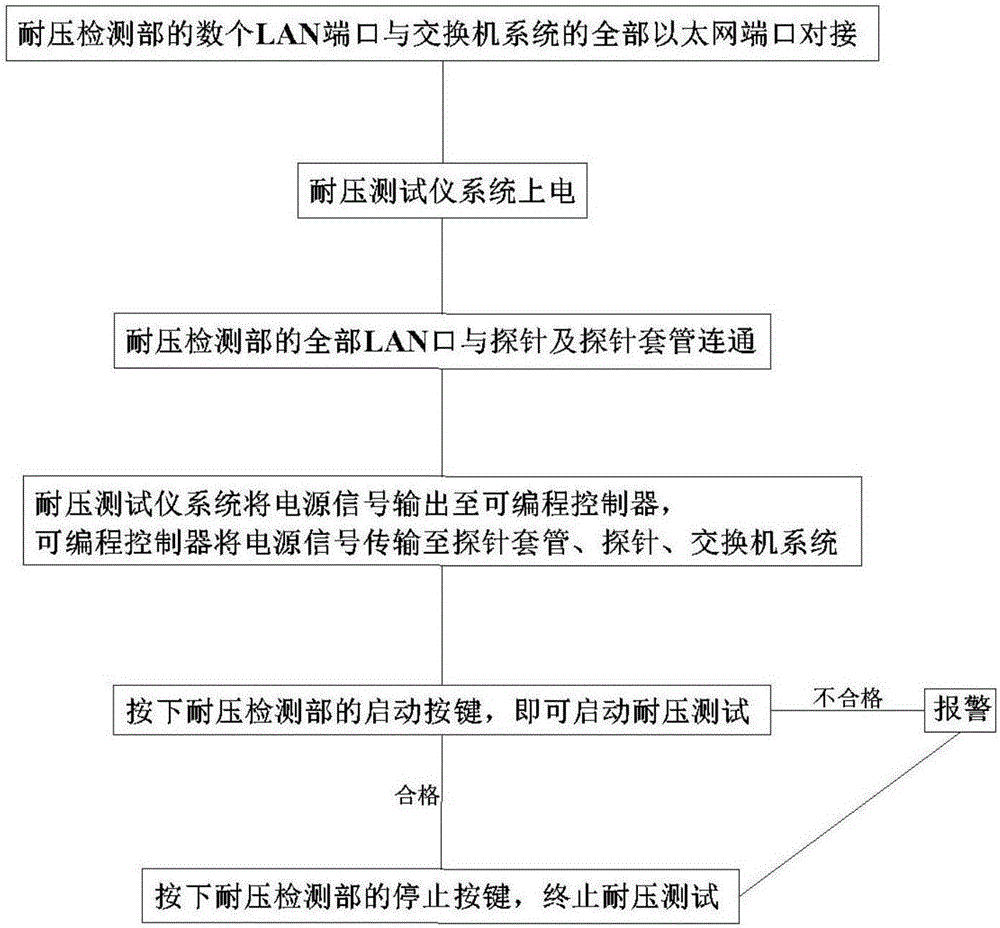

[0054] Such as image 3 As shown, this embodiment discloses a detection method based on the switch withstand voltage detection system of Embodiment 1, including the following steps:

[0055] S1. The 24 Ethernet ports of the switch use RJ45 cables to connect with the 24 LAN ports of the pressure testing department, which is convenient for testing the electrical performance of the whole machine covering the multi-Ethernet port switch, and testing whether the switch has a design The phenomenon of abnormal structure enables timely feedback and monitoring of product safety issues, so as to ensure that the development and design of the system have no exposed defects and provide users with innovative, stable and high-quality products;

[0056]S2. The power supply of the withstand voltage tester is connected to the power socket equipped with an AC regulated power supply, and the power signal is transmitted to the withstand voltage tester through the AC regulated power supply, so that ...

Embodiment 3

[0065] Apply the voltage withstand detection system of the switch in embodiment 1 and the withstand voltage detection method of the switch in embodiment 2 to the actual case, take the FS3526X 10 Gigabit aggregation switch of Phicomm model, and the FS3526X switch adopts Broadcom chip, which is a standard The non-blocking backbone 10 Gigabit aggregation switch has a switching capacity of 256Gbps and a packet forwarding rate of 156Mpps. It provides full wire-speed forwarding and has flexible networking capabilities to ensure stable operation of the network and load balancing of links. The fixed ports of the FS3526X switch include 24 10 / 100 / 10001Base-T Ethernet ports, 2 10GBase-X SFPs and 1 Console port.

[0066] The withstand voltage detection steps of the FS3526X 10 Gigabit aggregation switch are as follows:

[0067] S1. Connect the 24 Ethernet ports of the FS3526X switch to the 24 LAN ports of the withstand voltage detection department using RJ45 cables;

[0068] S2. Connect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com