AOI component detection frame automatic generation method based on PCB coordinate transformation

A technology of coordinate transformation and automatic generation, which is applied in the field of image processing, can solve problems such as difficult development and impact on program running time, and achieve the effects of perfect functions, rich algorithms, and improved detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

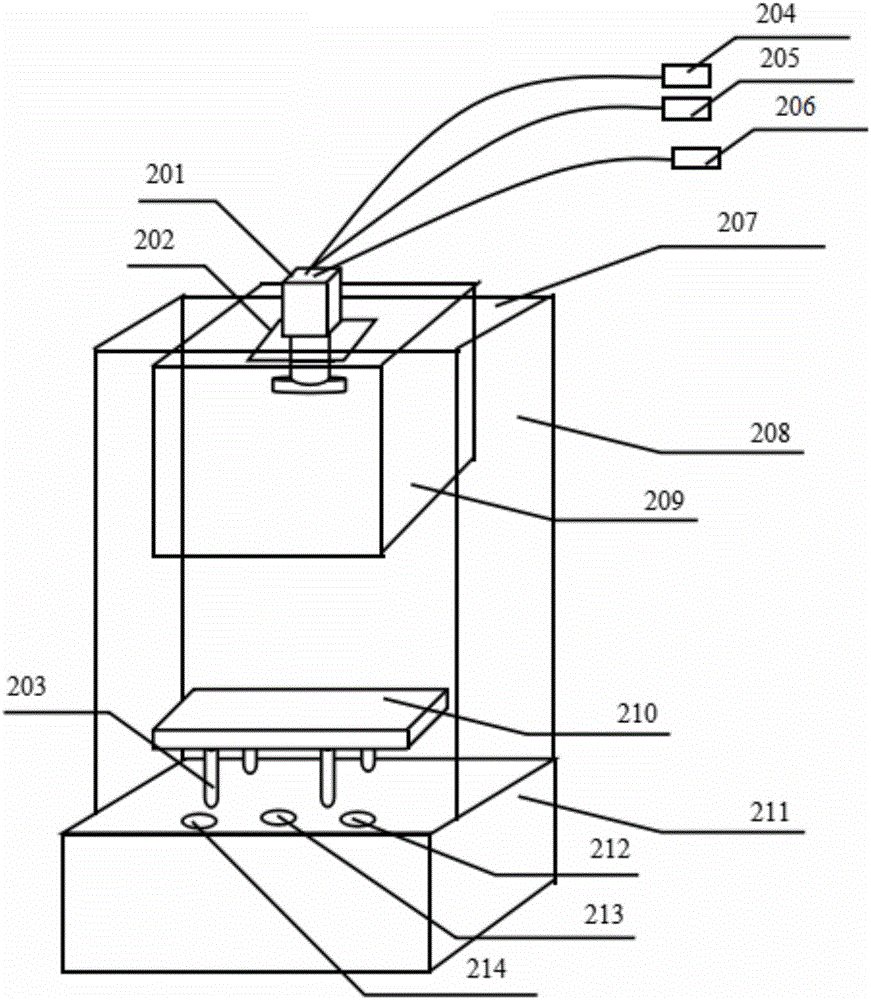

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

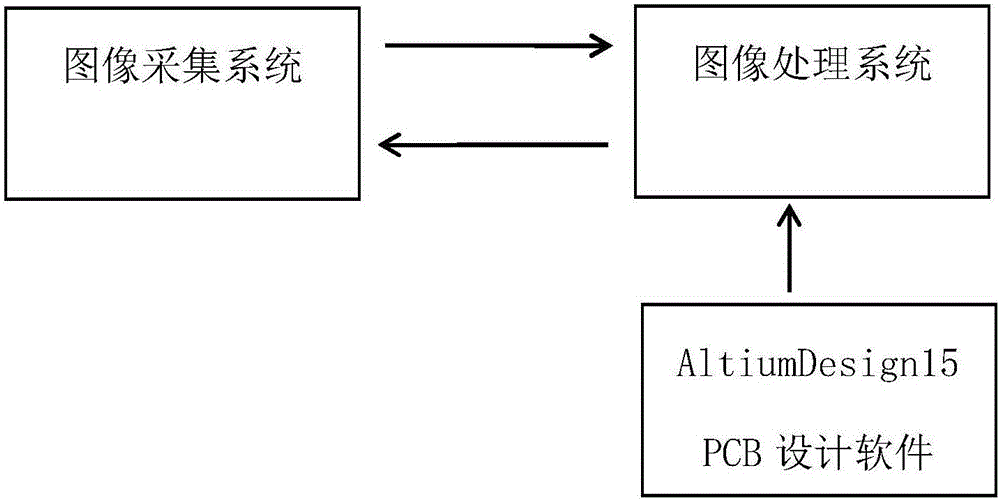

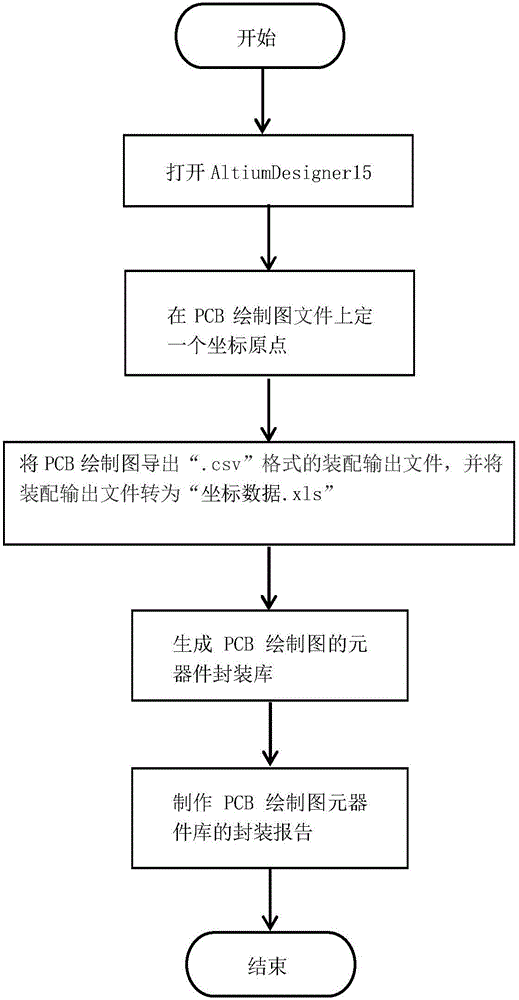

[0036] Such as Figure 4 As shown, the method of automatically generating AOI component detection frame based on PCB coordinate transformation is as follows:

[0037] Step 1, such as image 3 As shown, use Altium Desiger 15 drawing software to export the assembly output file and component packaging report of the PCB drawing, as follows:

[0038] 1.1 Import the project of the PCB drawing in the Altium Desiger 15 drawing software, and determine a coordinate point on the PCB drawing as the origin of the relative position of the components.

[0039] 1.2 In the Altium Designer 15 software, export the PCB drawing as an assembly output file in ".csv" format, and convert the assembly output file into a file "coordinate data.xls", and save it in the "PCB project name + PCB data" folder middle.

[0040] 1.3 Generate the component package library of the PCB dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com