Self-steering water and fertilizer integrated mulch film recovery machine

A technology of self-steering and recycling machines, which is applied in collectors, fertilization devices, watering devices, etc., can solve the problems of not being suitable for the film harvesting function between ridges, and achieve the advantages of resource recycling, simplified structure, and high degree of reuse. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

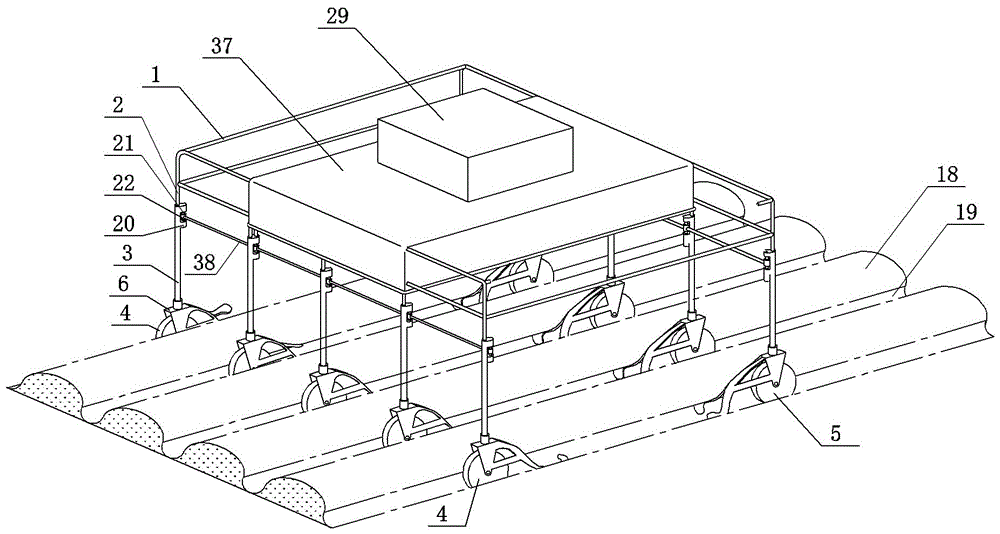

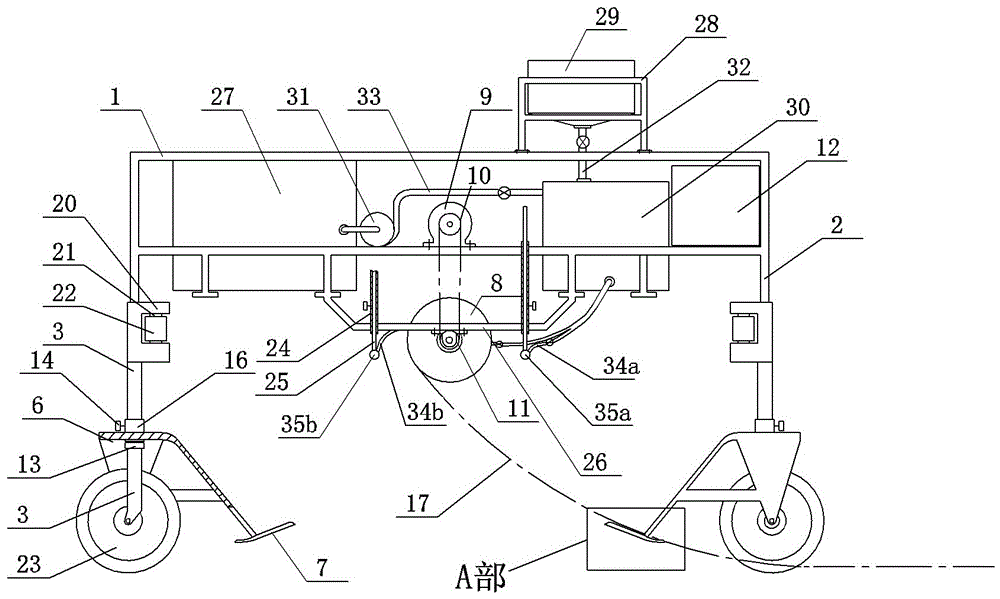

[0032] Example 1: A self-turning water and fertilizer integrated plastic film recovery machine, see figure 1 , The frame 1 is a frame type, and the outer side can be wrapped with a casing.

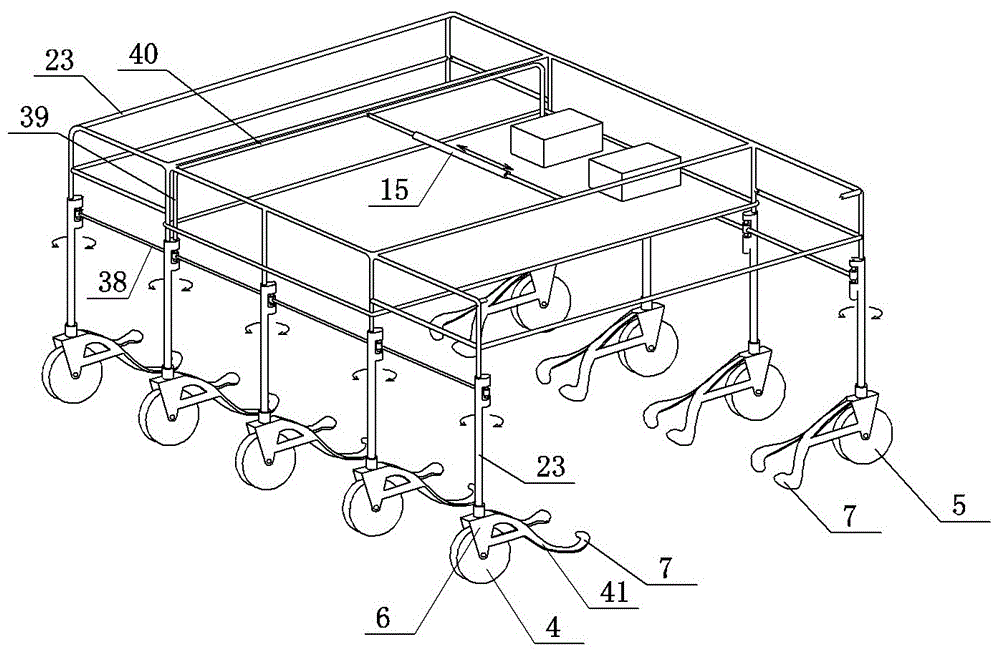

[0033] See figure 2 with Figure 4 , The front and rear ends of the frame 1 are provided with legs 2 at positions corresponding to the ditch. Under each leg 2 are sleeves 3, motor wheels 4 or follower wheels 5 (some of them are motor wheels 4, others are follower wheels). 5) Installed at the lower end of bushing 3, equipped with storage battery and controller. The follower wheel 5 adopts a universal wheel structure. The self-propelled design of motor wheel 4 is adopted, which does not require the participation of large-scale traction machinery, so it is suitable for the recycling of ridges and ditch-type crop mulch films. It can go deep into multiple ridges and walk along the ditch to collect the film. The entire film can be recycled, and there is no decay film. Residual problems.

[0034] I...

Embodiment 2

[0040] Example 2: Another self-turning water and fertilizer integrated mulch film recovery machine. Based on Example 1, the part of the integrated water and fertilizer spraying system is changed: a rotating shaft is installed in the middle of the lower part of the frame 1, and the rotating shaft is installed The front and rear ends of the symmetric yaw rod 39 are respectively connected with a front drain pipe and a rear drain pipe. The front drain pipe and the rear drain pipe are respectively connected to the mixing tank through the front discharge pipe and the rear discharge pipe. The front liquid outlet pipe and the rear liquid outlet pipe are respectively provided with front and rear valves. A linkage rod is provided between the front and rear valves and the frame 1 respectively. When any valve swings upward, the linkage rod pulls to close the valve, and when any valve swings downward, the linkage rod pushes to open the valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com