Floating kelp harvesting machine

A harvester and kelp technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of inability to meet the high efficiency requirements of modern machinery, difficult to meet the requirements of offshore operations, and high labor intensity of workers, and achieve the labor intensity of workers. Low, reasonable and reliable structure innovation, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

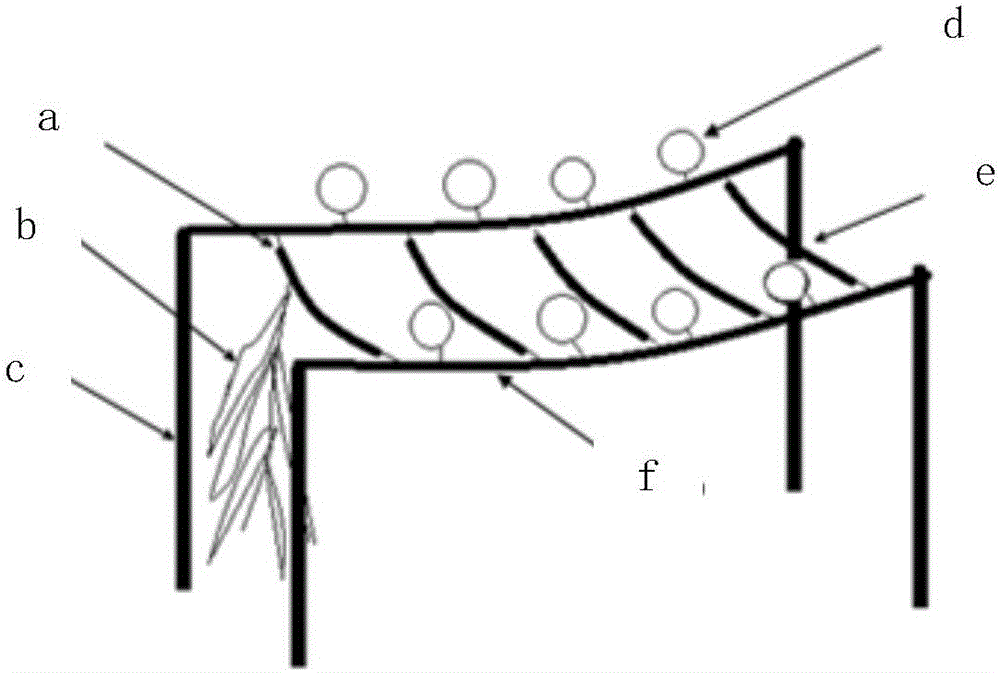

[0020] as attached figure 1 As shown, the kelp culture raft mainly includes pile c, pile rope f, seedling rope e, hanging rope a and floating ball d. The piles are generally made of bamboo or wood to support the kelp and the pile rope; the pile rope is used to The rope connecting the kelp and the pile is generally made of polyethylene; the role of the seedling rope is to clamp the kelp; the role of the sling is to adjust the depth of the kelp in the sea; the floating ball mainly plays the role of marking.

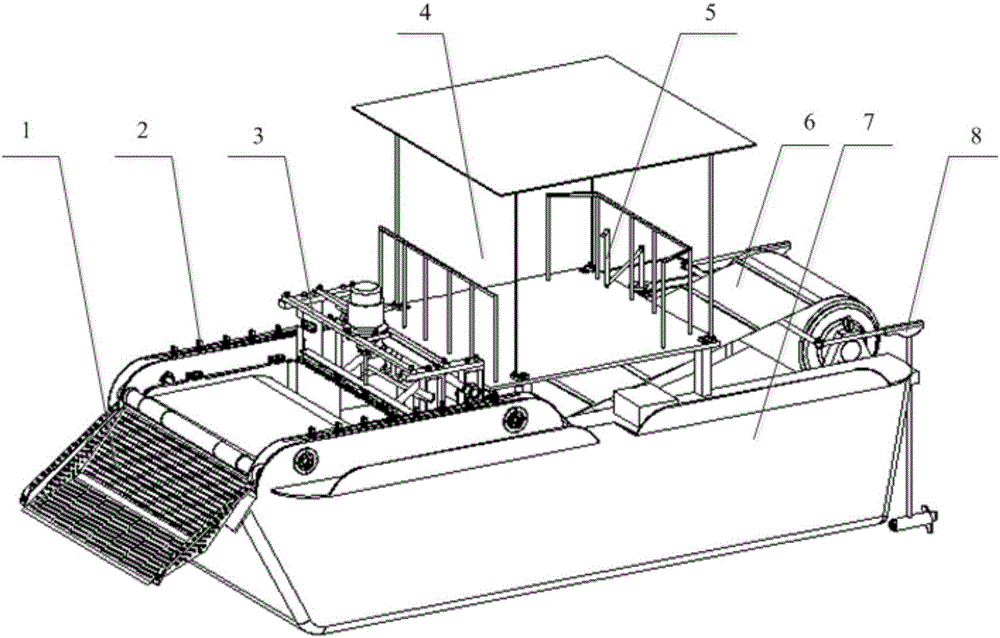

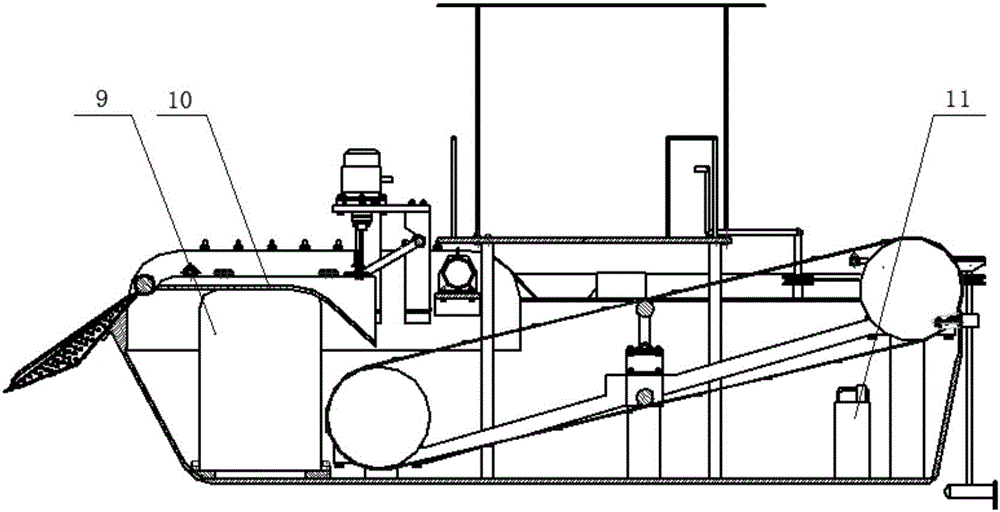

[0021] as attached Figure 2a As shown in -b, the floating kelp harvester mainly includes a guiding device 1, a traction device 2, a cutting device 3, an operating room 4, a steering mechanism 5, a conveying device 6, a hull 7, a marine propeller 8, a diesel generator set 9, Partition plate 10, stainless steel submersible pump 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com