Sweet potato starch food quick-freezing and refrigeration method

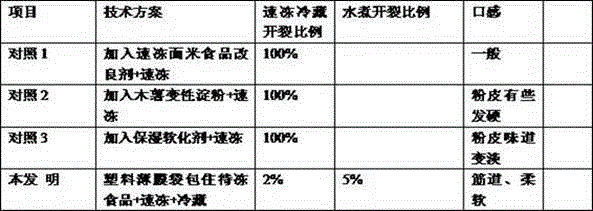

A potato starch and food technology, which is applied in the field of quick-frozen red (white) potato starch food antifreeze cracking and water retention, and can solve problems that affect eating and appearance, easy to lose water, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Implementation 1: According to the standard requirements for the manufacture of quick-frozen food, before the red (white) potato starch food is quickly put into the quick-freezing device after being formed, the food to be frozen is directly wrapped in a food-grade plastic film bag. The size and specification of the film bag can be convenient Fully trap the food to be frozen without leaving too much space, the bag mouth can be twisted and sealed tightly, so that the food in the bag can retain moisture to the maximum extent during quick freezing and prevent cracking. After the quick freezing is completed, the food is packed with film and sent to the cold storage for storage. After the food is formed, it is put into a device at -25°C for quick freezing. After the quick freezing is completed, the central temperature of the food reaches below -10°C. The cold storage of the quick-frozen food also requires the temperature of the cold storage to be kept at -10°C;

[0030] The i...

Embodiment 2

[0031] Implementation 2: After the food is formed, quickly put it into a -30°C device for quick freezing. After the quick freezing is completed, the central temperature of the food reaches below -15°C. The cold storage of the quick frozen food also requires the temperature of the cold storage to be kept at -15°C;

[0032] Other technical solutions are the same as Implementation 1;

[0033] The integrity rate of the quick-frozen buns is over 98%. During the cooking process, 3% of the red (white) potato starch food is cracked or the stuffing is opened.

Embodiment 3

[0034] Implementation 3: After the food is formed, put it into a device at -35°C for quick freezing. After the quick freezing, the central temperature of the food must be below -18°C. After quick freezing, the temperature of the cold storage is also required to be kept at -18°C.

[0035] Other technical schemes are identical with implementation 1.

[0036] The integrity rate of the quick-frozen buns is over 99%. During the cooking process, the red (white) potato starch food is cracked or the filling is missing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com