Five cereals and five beans compound coarse cereal porridge and making method thereof

A production method and a technology for miscellaneous grain porridge, which are applied in the field of food processing, can solve the problems of inability to meet meal requirements, taking a certain amount of time, and separating the taste of rice grains and rice milk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] A kind of multigrain porridge with five grains and five beans, which is characterized in that its components and weight percentages are 25% of yam grains, 16% of red bean grains, 12% of mung bean grains, 9% of purple kidney bean grains, 9% of corn grains, and 6% of black rice grains. %, tomato 5%, white kidney bean 3%, barley 3%, carrot 3%, cooked oatmeal 1%, millet 2%, sorghum 2%, rhubarb 2%, and pea 2%.

[0102] The eating method of the five-grain and five-bean compound grain porridge is as follows: put the porridge grains into a container and soak them in hot water at 95°C. The mass ratio of hot water to porridge grains is 7.5:1. Cover the container during soaking and use it before covering. Spoon to stir well, brewing time is 15 minutes.

[0103]The preparation method of the multigrain porridge with five grains and five beans comprises the following steps:

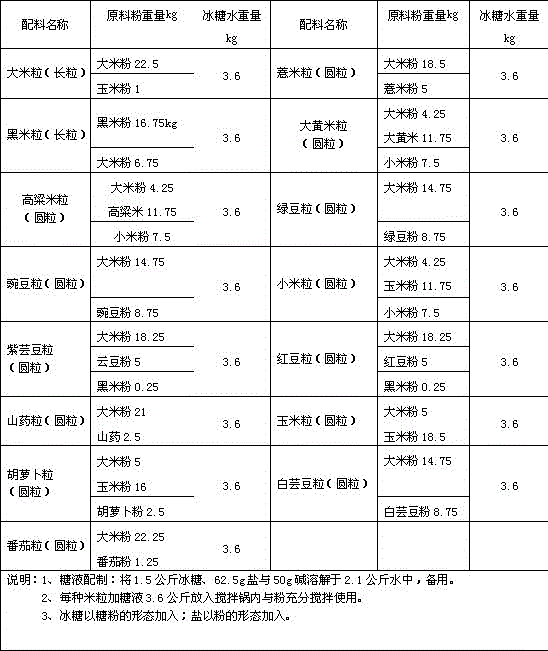

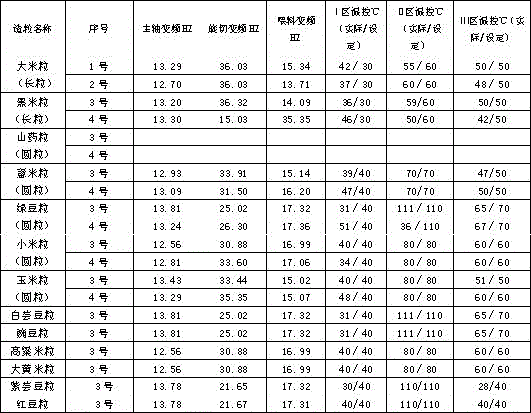

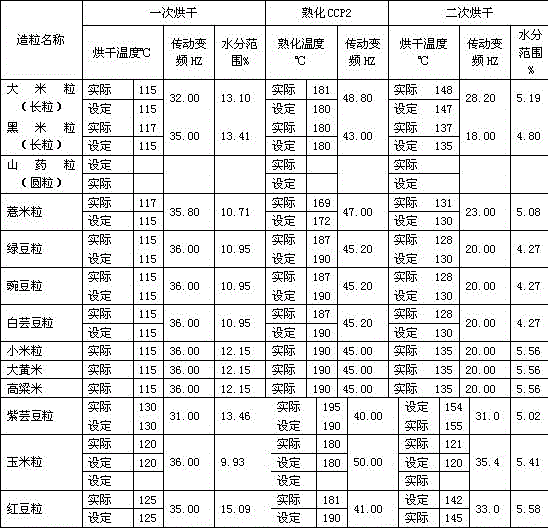

[0104] Step a, the preparation process of rice grains: wherein rice grains and black rice grains are long gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com