A dental implant with periodontal ligament-like structure design

A dental implant and membrane structure technology, applied in dentistry, dental implants, medical science, etc., can solve the problems of large investment and long time, and achieve the effects of reducing production costs, dispersing occlusal load, and reducing exploration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

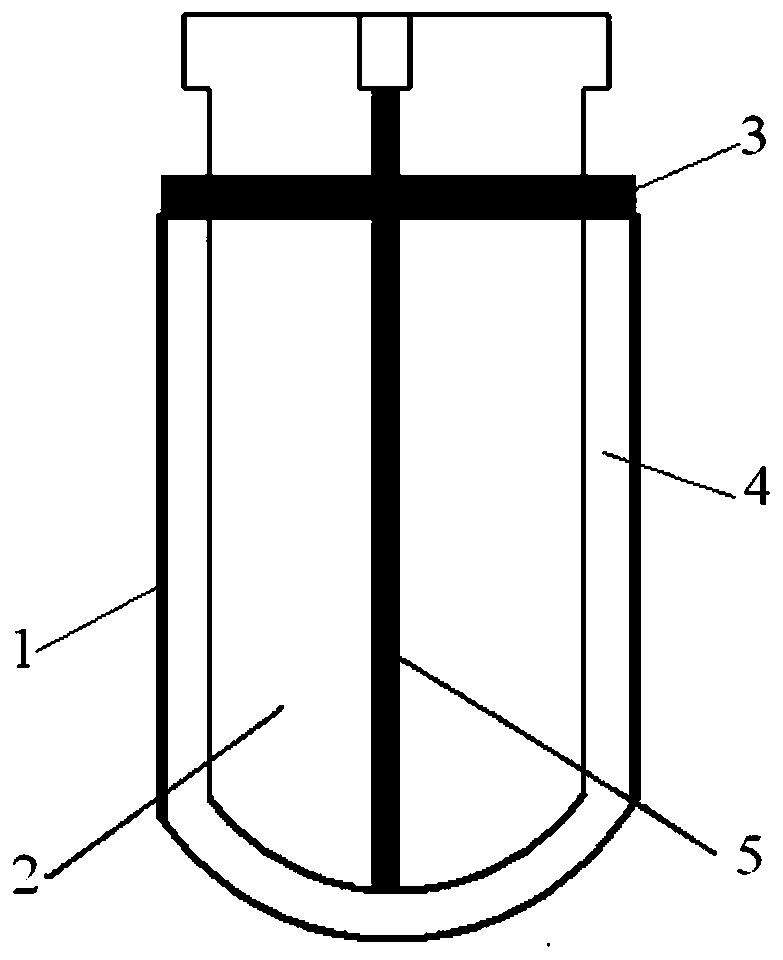

[0027] The implant shell 1 is made of titanium metal, and the surface is treated with sand blasting, acid etching, and surface calcium phosphating to improve the bonding ability of the implant material and bone. The inner surface of the implant shell 1 can be roughened by sandblasting, and the roughness Ra is 3um, which can suspend and lift the elastic buffer layer material.

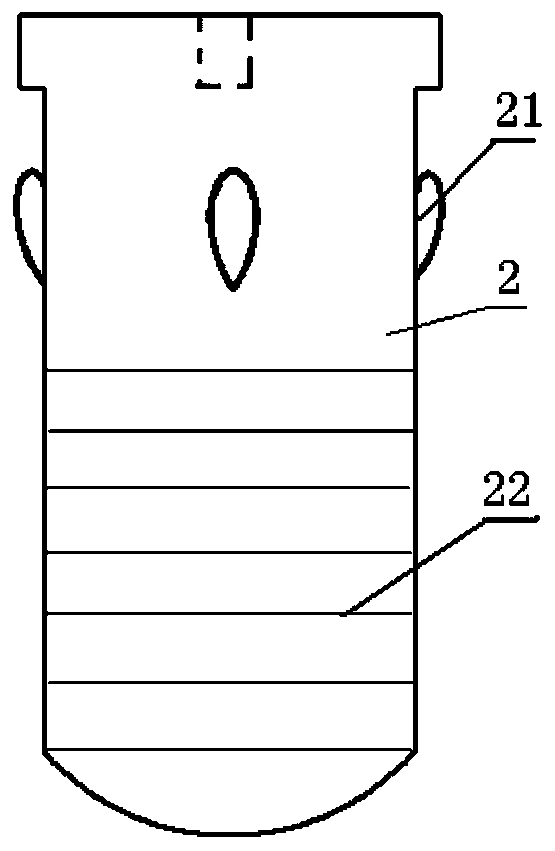

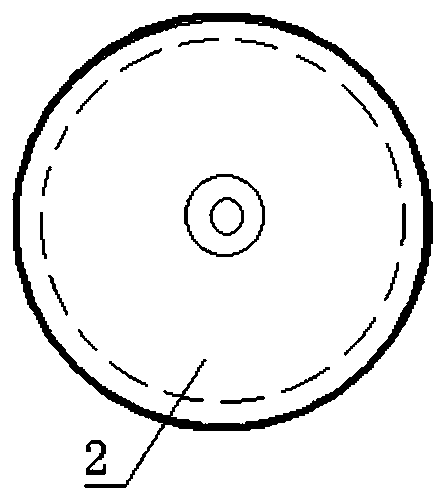

[0028] The implant inner core 2 is installed in the implant shell 1 , and its shape is consistent with the hollow cylinder of the implant shell 1 . The surface of the inner core of the implant is subjected to laser surface patterning to form rough grooves with a width of 6 μm and a depth of 6 μm, further increasing the suspension and pulling effect on the elastic buffer layer.

[0029] The material selected for the elastic buffer layer 4 and the locking and sealing member 3 is silicone rubber with an elastic modulus of 40Mpa and a Poisson's ratio of 0.45.

Embodiment 2

[0031] The implant casing 1 is made of Ti6Al4V metal, and the surface is sandblasted, acid-etched, and surface calcium phosphated to improve the bonding ability of the implant material and bone. The inner surface of the implant shell can be roughened by sandblasting, and the roughness Ra is 7um, which can suspend and lift the material of the elastic buffer layer 4 .

[0032] The implant inner core 2 is installed in the implant shell 1 , and its shape is consistent with the hollow cylinder of the implant shell 1 . The surface of the inner core 2 of the implant is subjected to laser surface patterning treatment to form stripes perpendicular to the cross section with a width of 10 μm and a depth of 4 μm, further increasing the suspension and pulling effect on the elastic buffer layer.

[0033] The material selected for the elastic buffer layer 4 and the locking and sealing member 3 is silicone rubber with an elastic modulus of 65Mpa and a Poisson's ratio of 0.49.

Embodiment 3

[0035] The implant casing 1 is made of TiZrNbSn metal, and the surface is treated with sandblasting, acid etching, and surface calcium phosphating to improve the bonding ability of the implant material and bone. The inner surface of the implant shell 1 can be roughened by sandblasting, and the roughness Ra is 5um, which can suspend and lift the elastic buffer layer material.

[0036] The implant inner core 2 is installed in the implant shell 1, and its shape is consistent with the hollow cylinder of the implant shell. The surface of the inner core 2 of the implant is subjected to laser surface patterning treatment to form a rough surface with a roughness of Ra 5um, which further increases the suspension and lifting effect on the elastic buffer layer.

[0037] The material selected for the elastic buffer layer 4 and the locking and sealing member 3 is silicone rubber with an elastic modulus of 35Mpa and a Poisson's ratio of 0.35.

[0038] When implanting a tooth, first, the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com