Compound air purifier, preparation method of compound air purifier, and air purifying device

A technology of air purifier and accelerator, which is applied in the direction of chemical instruments and methods, separation methods, physical/chemical process catalysts, etc., to achieve the effects of simple use, good adsorption conversion effect, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

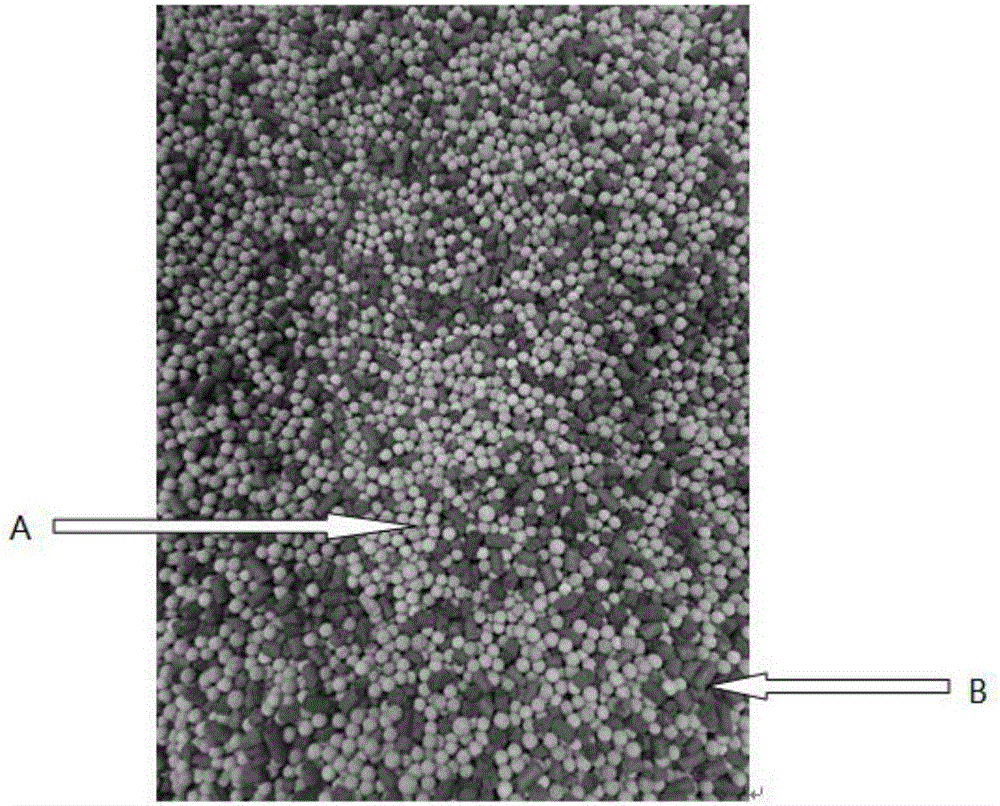

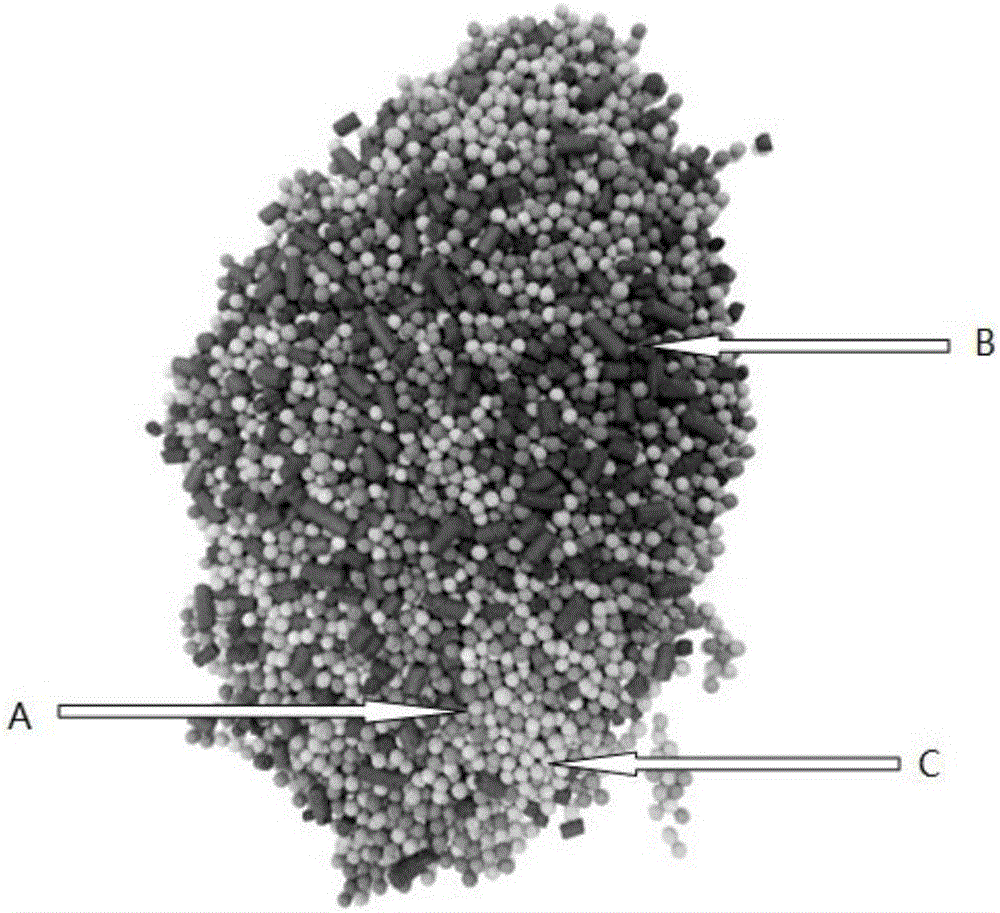

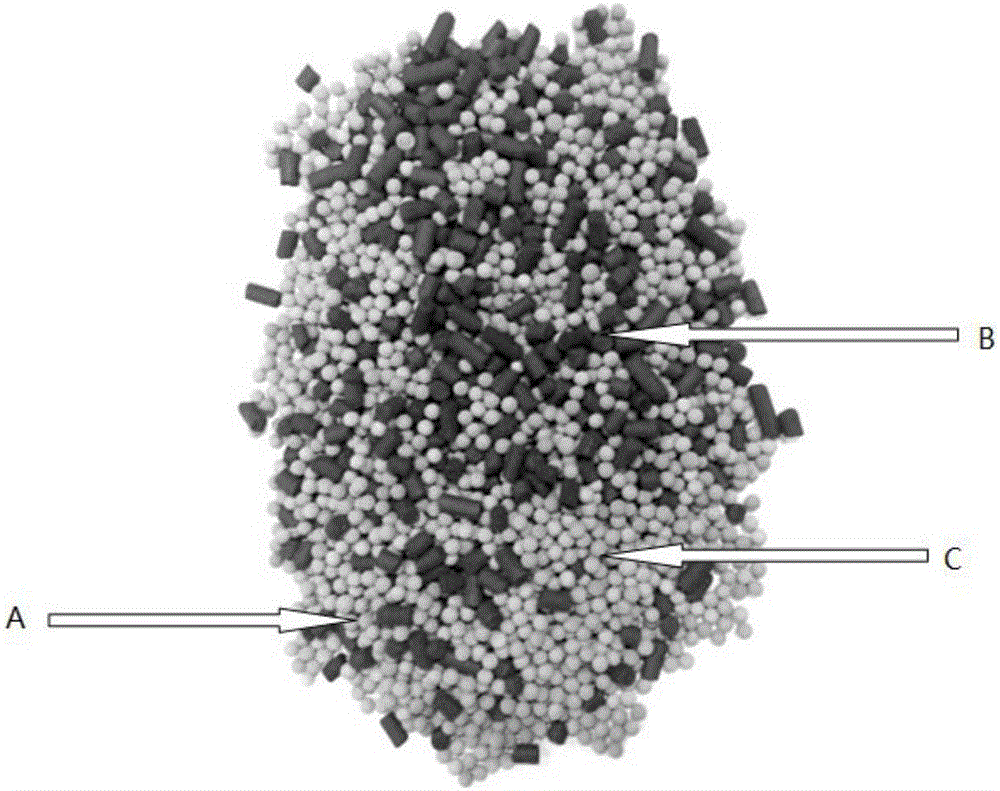

Image

Examples

preparation example Construction

[0040] A preparation method of composite air purifier, comprising the following steps:

[0041] 1) Preparation of component I: take a non-polar carrier, add it to the active component A solution, soak and filter to obtain a carrier loaded with active component A; let the carrier loaded with active component A stand until there is no liquid drop out, then dry and cool naturally to obtain component I;

[0042] 2) Preparation of component II: take the polar carrier, add it to the solution D containing the active component B and the accelerator C, and after impregnating and filtering, obtain the carrier loaded with the active component B and the accelerator C; The carrier of Component B and Accelerator C is allowed to stand until no liquid drips out, and after drying and natural cooling, Component II is obtained;

[0043] 3) Compounding: According to the proportioning ratio of the formula, component I and component II are evenly mixed in a certain proportion to obtain the composi...

Embodiment 1

[0045] The specific surface area is 420m 2 / g, the pore volume is 0.22cm 3 Put 100g of activated carbon per gram into 330g of KOH solution with a mass fraction of 3.5%, soak for 4.5 hours, filter, stand until no liquid drips out, then dry at 105°C and cool naturally to obtain component I;

[0046] The specific surface area is 220m 2 / g, the pore volume is 0.32cm 3 / g of alumina 100g, put in 220g containing 3.5wt% KMnO 4 and 0.005wt% silver nitrate solution, immerse for 4.5 hours, filter, stand until no liquid drips out, then dry at 55°C and cool naturally to obtain component II;

[0047] The composite air purifier of the present invention is obtained by mixing component I and component II according to the weight ratio of component I: component II of 1:1.

Embodiment 2

[0049] The specific surface area is 650m 2 / g, the pore volume is 0.38cm 3 100g of active carbon / g, put into 380g mass fraction and be 3.5% K 2 FeO 4 Immerse in the solution for 5.5 hours, filter and stand until no liquid drips out, then dry at 115°C and cool naturally to obtain component I;

[0050] The specific surface area is 350m 2 / g, the pore volume is 0.35cm 3 / g of alumina 100g, put in 250g containing 3.5wt% KMnO 4 and 0.005wt% silver nitrate solution, immerse for 5.5 hours, filter, stand until no liquid drips out, then dry at 200°C and cool naturally to obtain component II;

[0051] The composite air purifier of the present invention is obtained by mixing component I and component II according to the weight ratio of component I: component II of 1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com