Polyformaldehyde dimethyl ether production catalyst

A polyoxymethylene dimethyl ether and catalyst technology, which is applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, organic chemistry and other directions, can solve the problem of high cost of trioxymethylene, low catalyst reaction efficiency, etc. problem, to achieve good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

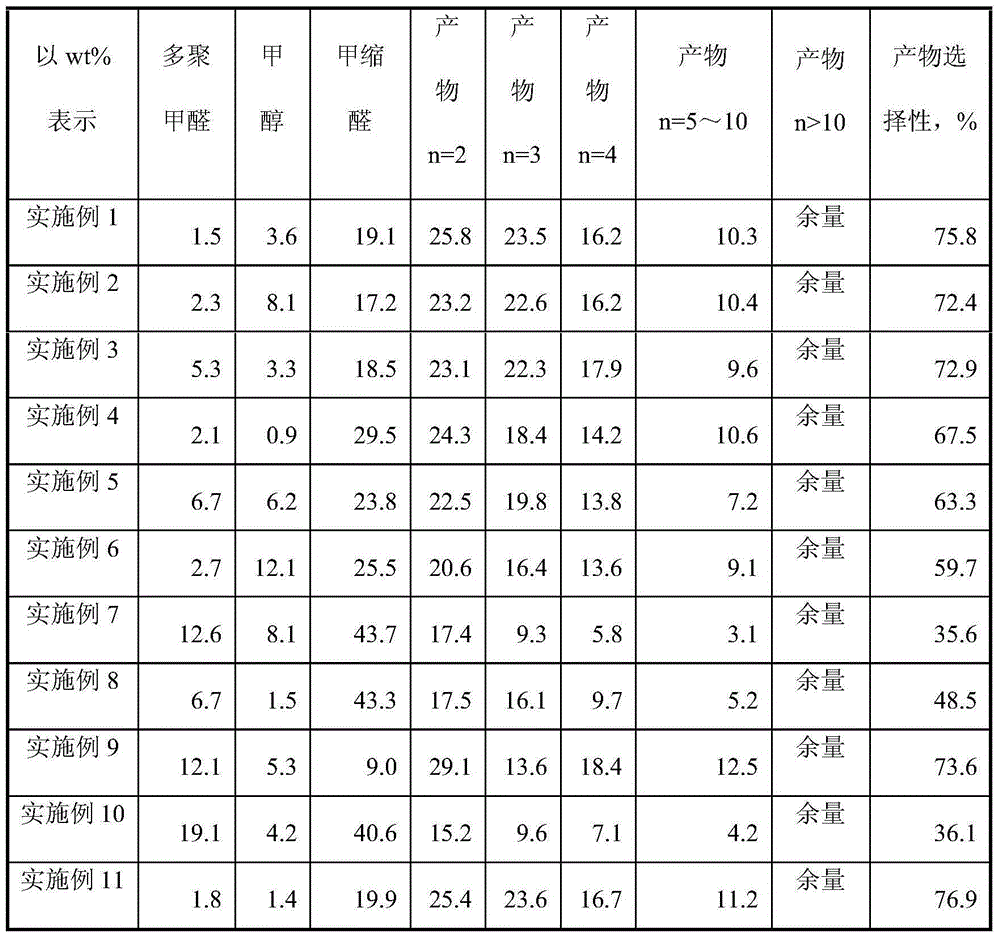

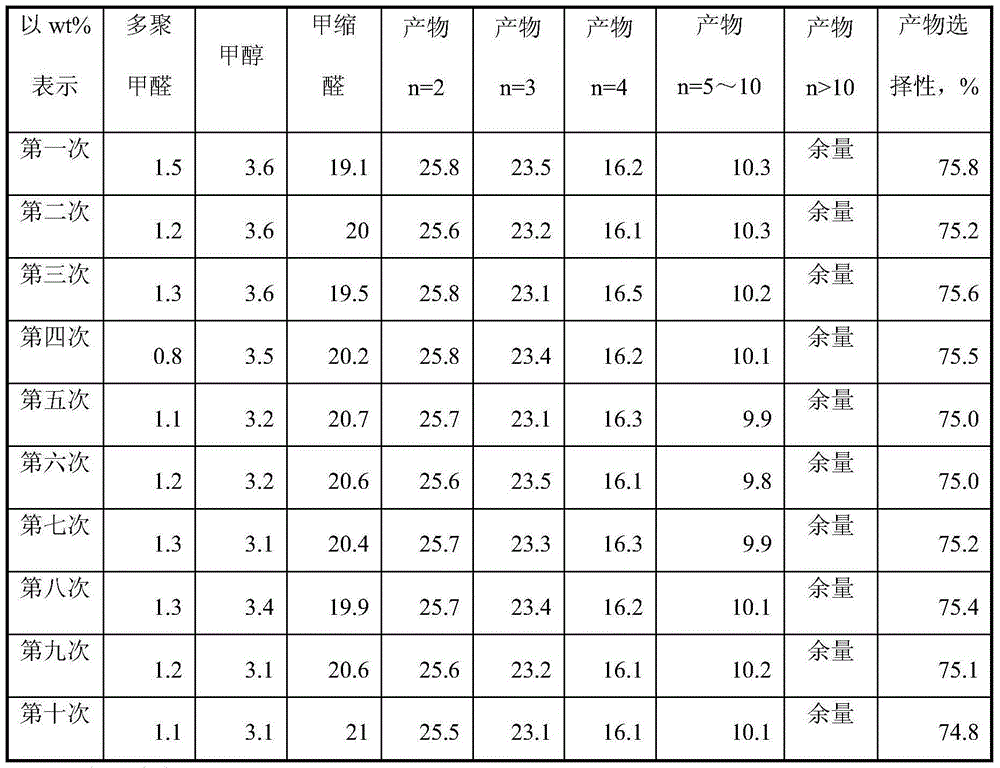

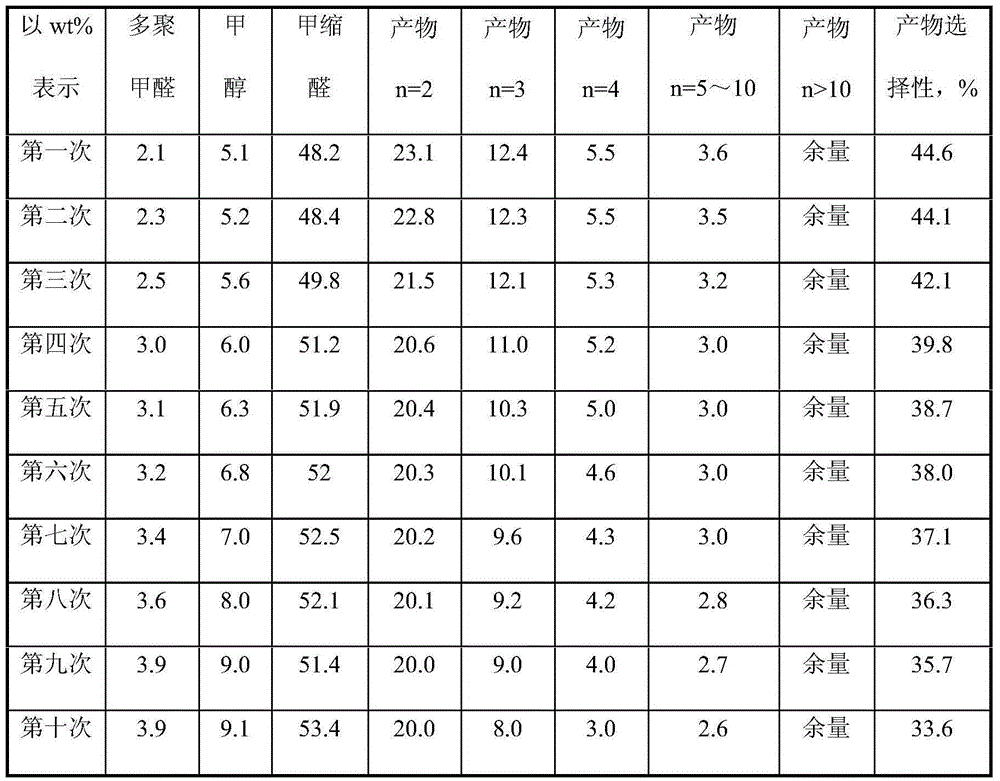

Examples

Embodiment 1

[0020] 1. Preparation of catalyst

[0021] (1) Polymerization and hybridization: at room temperature, add 144 grams of styrene, 16 grams of divinylbenzene, 1 gram of BPO and 40 grams of toluene into a 1000 ml three-necked flask and stir evenly, then add 500 mesh Dy 3 Fe 5 o 12 40g, stir evenly, add 300g of 1.0w% PVA aqueous solution, then react at 70°C for 3h, 80°C for 1h, and 95°C for 45min under stirring, to obtain a pellet-shaped product, stop stirring, and keep 95°C to cook Ball 30min. All the products in the three-necked flask were poured into water for cleaning. The product was washed with ethanol and then washed with H 2 O was washed, placed in an oven and dried at 80° C. for 4 h to obtain 200 g of catalyst precursor I.

[0022] (2) Sulfonation: Add 200 grams of catalyst precursor I to 400 grams of 1,2-dichloroethane to swell at room temperature for 4 hours, then add 100 grams of H with a purity of 98w%. 2 SO 4 , stirring and downloading at 85°C for 3h, and then ...

Embodiment 2

[0029] 1. Preparation of catalyst

[0030] (1) Polymerization and hybridization: at room temperature, add 144 grams of styrene, 16 grams of divinylbenzene, 1 gram of BPO and 40 grams of toluene into a 1000 ml three-necked flask and stir evenly, then add 500 mesh Ho 3 Fe 5 o 12 40g, stir evenly, add 300g of 1.0w% PVA aqueous solution, then react at 70°C for 3h under stirring, 1h at 80°C, and 45min at 95°C to obtain a pellet-shaped product, stop stirring, and boil at 95°C Ball 30min. All the products in the three-necked flask were poured into water for cleaning. The product was washed with ethanol and then washed with H 2 O was washed, placed in an oven and dried at 80° C. for 4 h to obtain 200 g of catalyst precursor I.

[0031] (2) Sulfonation: Add 200 grams of catalyst precursor I to 400 grams of 1,2-dichloroethane to swell at room temperature for 4 hours, then add 100 grams of H with a purity of 98w%. 2 SO 4 , stirring and downloading at 85°C for 3h, and then at 110°C...

Embodiment 3

[0036] 1. Preparation of catalyst

[0037] (1) Polymerization and hybridization: at room temperature, add 144 grams of styrene, 16 grams of divinylbenzene, 1 gram of BPO and 40 grams of toluene to a 1000 ml three-necked flask and stir evenly, then add 500 mesh Er 3 Fe 5 o 12 40g, stir evenly, add 300g of 1.0w% PVA aqueous solution, then react at 70°C for 3h under stirring, 1h at 80°C, and 45min at 95°C to obtain a pellet-shaped product, stop stirring, and boil at 95°C Ball 30min. All the products in the three-necked flask were poured into water for cleaning. The product was washed with ethanol and then washed with H 2 O was washed, placed in an oven and dried at 80° C. for 4 h to obtain 200 g of catalyst precursor I.

[0038] (2) Sulfonation: Add 200 grams of catalyst precursor I to 400 grams of 1,2-dichloroethane to swell at room temperature for 4 hours, then add 100 grams of H with a purity of 98w%. 2 SO 4 , stirring and downloading at 85°C for 3h, and then at 110°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com