The preparation method of polyoxymethylene dimethyl ether

A technology of dimethyl ether and polyoxymethylene, which is used in the preparation of organic compounds, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of low catalyst reaction efficiency and high cost of trioxymethylene problem, to achieve the effect of low production cost, high product yield and high reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

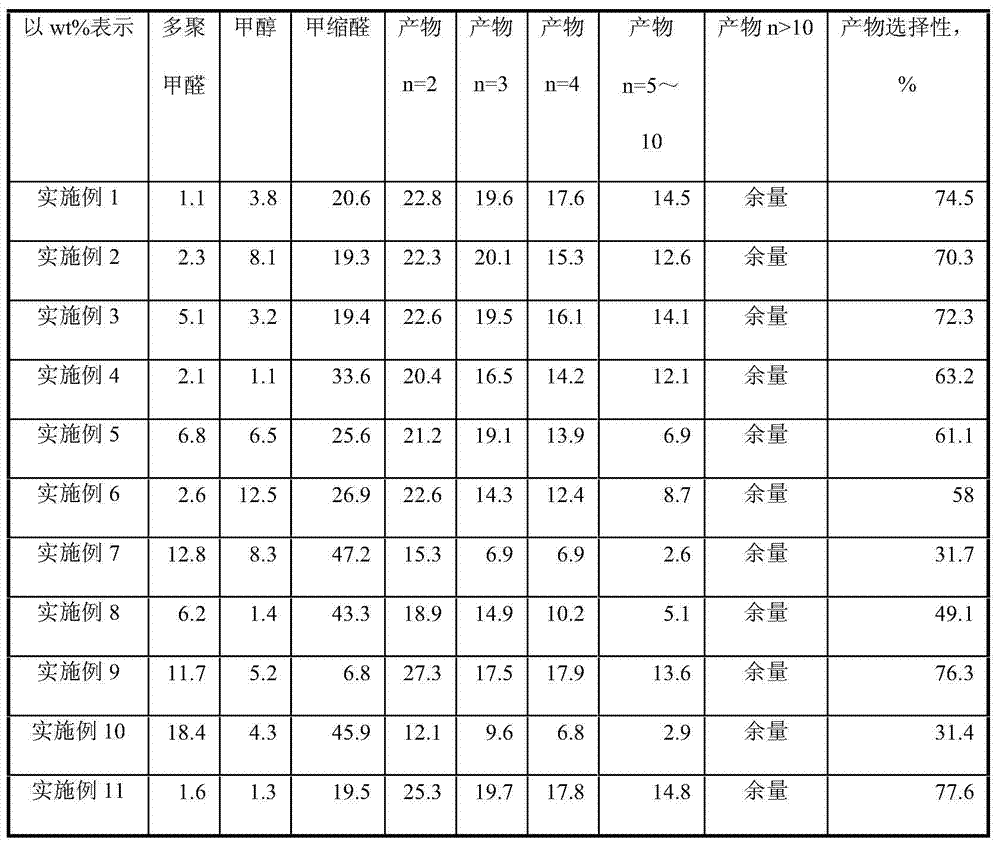

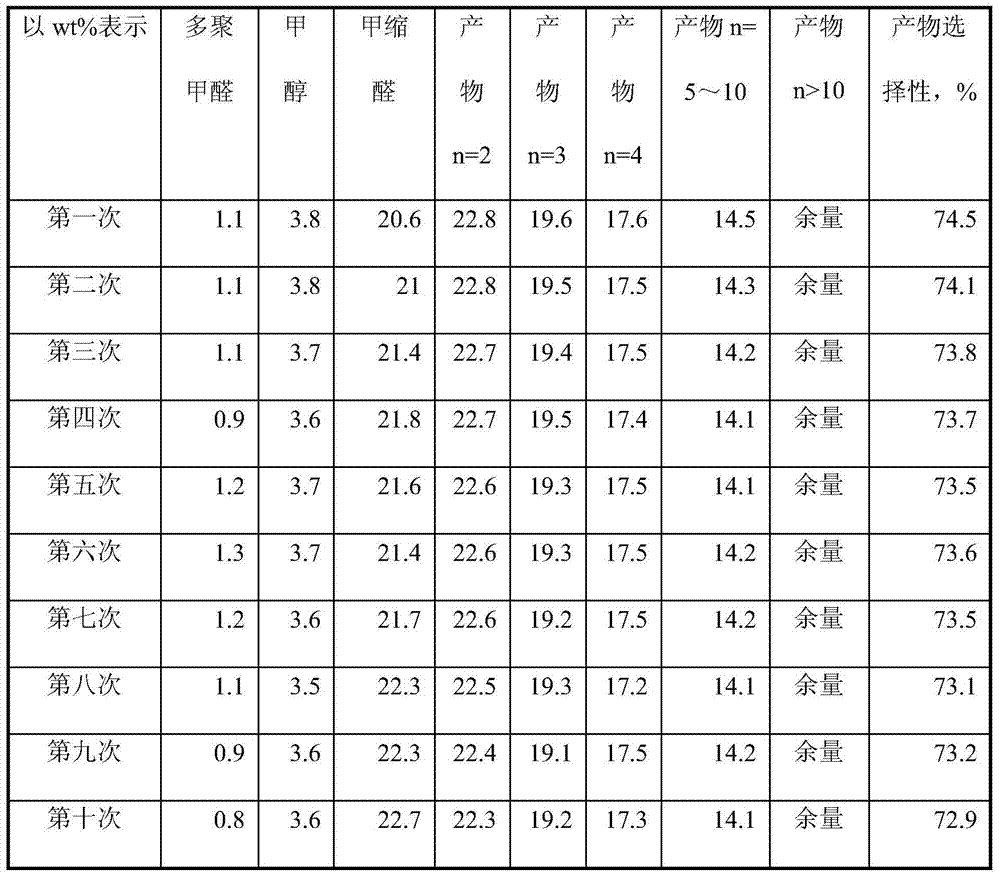

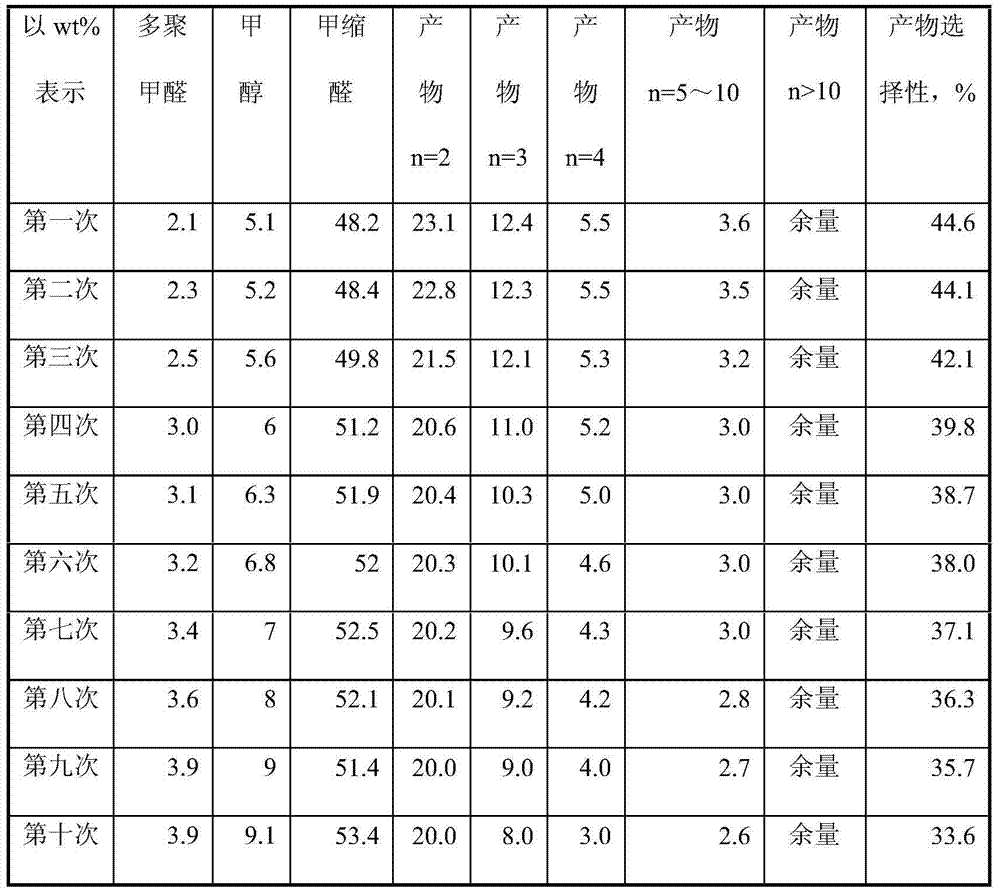

Examples

Embodiment 1

[0027] 1. Preparation of catalyst

[0028] (1) Polymerization and hybridization: at room temperature, add 144 grams of styrene, 16 grams of divinylbenzene, 1 gram of BPO and 40 grams of toluene to a 1000 ml three-necked flask and stir evenly, then add 40 grams of 500-mesh copper oxide, and stir Evenly, add 300 grams of 1.0w% PVA aqueous solution, then react at 70°C for 3 hours, 80°C for 1 hour, and 95°C for 45 minutes under stirring to obtain a pellet-shaped product. Stop stirring and keep boiling the pellets at 95°C for 30 minutes. All the products in the three-necked flask were poured into water for cleaning. The product was washed with ethanol and then washed with H 2 O was washed, placed in an oven and dried at 80° C. for 4 h to obtain 200 g of catalyst precursor I.

[0029] (2) Sulfonation: Add 200 grams of catalyst precursor I to 400 grams of 1,2-dichloroethane to swell at room temperature for 4 hours, then add 100 grams of H with a purity of 98w%. 2 SO 4 , stirring ...

Embodiment 2

[0036] 1. Preparation of catalyst

[0037] (1) Polymerization and hybridization: at room temperature, add 144 grams of styrene, 16 grams of divinylbenzene, 1 gram of BPO and 40 grams of toluene to a 1000 ml three-necked flask and stir evenly, then add 40 grams of 500-mesh silicon oxide, and stir Evenly, add 300 grams of 1.0w% PVA aqueous solution, then react at 70°C for 3 hours, 80°C for 1 hour, and 95°C for 45 minutes under stirring to obtain a pellet-shaped product. Stop stirring and keep boiling the pellets at 95°C for 30 minutes. All the products in the three-necked flask were poured into water for cleaning. The product was washed with ethanol and then washed with H 2 O was washed, placed in an oven and dried at 80° C. for 4 h to obtain 200 g of catalyst precursor I.

[0038] (2) Sulfonation: Add 200 grams of catalyst precursor I to 400 grams of 1,2-dichloroethane to swell at room temperature for 4 hours, then add 100 grams of H with a purity of 98w%. 2 SO 4 , stirring...

Embodiment 3

[0042] 1. Preparation of catalyst

[0043] (1) Polymerization and hybridization: at room temperature, add 144 grams of styrene, 16 grams of divinylbenzene, 1 gram of BPO and 40 grams of toluene to a 1000 ml three-necked flask and stir evenly, then add 40 grams of 500-mesh phosphorus oxide, and stir Evenly, add 300 grams of 1.0w% PVA aqueous solution, then react at 70°C for 3 hours, 80°C for 1 hour, and 95°C for 45 minutes under stirring to obtain a pellet-shaped product. Stop stirring and keep boiling the pellets at 95°C for 30 minutes. All the products in the three-necked flask were poured into water for cleaning. The product was washed with ethanol and then washed with H 2 O was washed, placed in an oven and dried at 80° C. for 4 h to obtain 200 g of catalyst precursor I.

[0044] (2) Sulfonation: Add 200 grams of catalyst precursor I to 400 grams of 1,2-dichloroethane to swell at room temperature for 4 hours, then add 100 grams of H with a purity of 98w%. 2 SO 4 , stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com