Material crushing device with cutter position adjustable type serrated cutter

A cutting tool and knife position technology, which is applied in the field of sawing equipment for metal block raw materials, can solve the problems of low efficiency in dissolving block materials, achieve the effects of reducing lifting time, reducing manufacturing and use costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

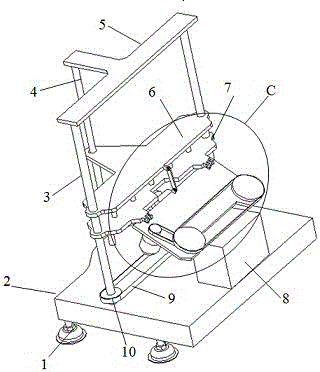

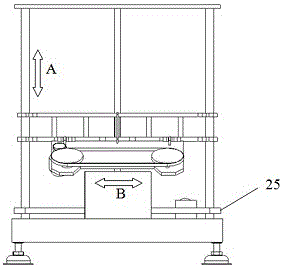

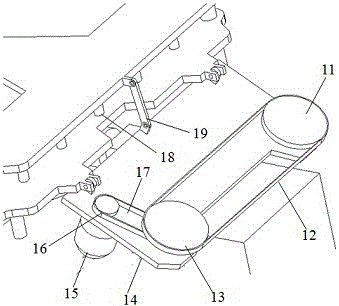

[0019] control Figure 1 to Figure 4 As shown in the illustration, the operator needs to adjust the positions of the upper sliding plate 6 and the lower sliding plate 7 according to the height of the block material 8 before starting the machine, and after starting the main servo motor 20, the reducer 21 passes through the main drive wheel 22 and The timing belt 23 of the main engine and the driven pulley 24 of the main engine make the side screw 3 rotate, and the side screw 3 drives the upper sliding plate 6 and the lower sliding plate 7 to move upward to a suitable position, and then the adjustable connecting rod 19 is used to adjust The included angle between the rotating plate 14 and the ground is to adjust the cutting angle of the saw blade 12. Finally, the block material 8 to be cut is placed under the saw blade 12. At this time, the device completes the preparatory work before the work.

[0020] When it is necessary to cut off the block material 8, start the device. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com