Rotating disk platform type steel structure assembly device

An assembly equipment, platform-type technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as difficulty in ensuring accuracy and product quality, and achieve improved flexibility, reduced risk of electric shock, and good versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

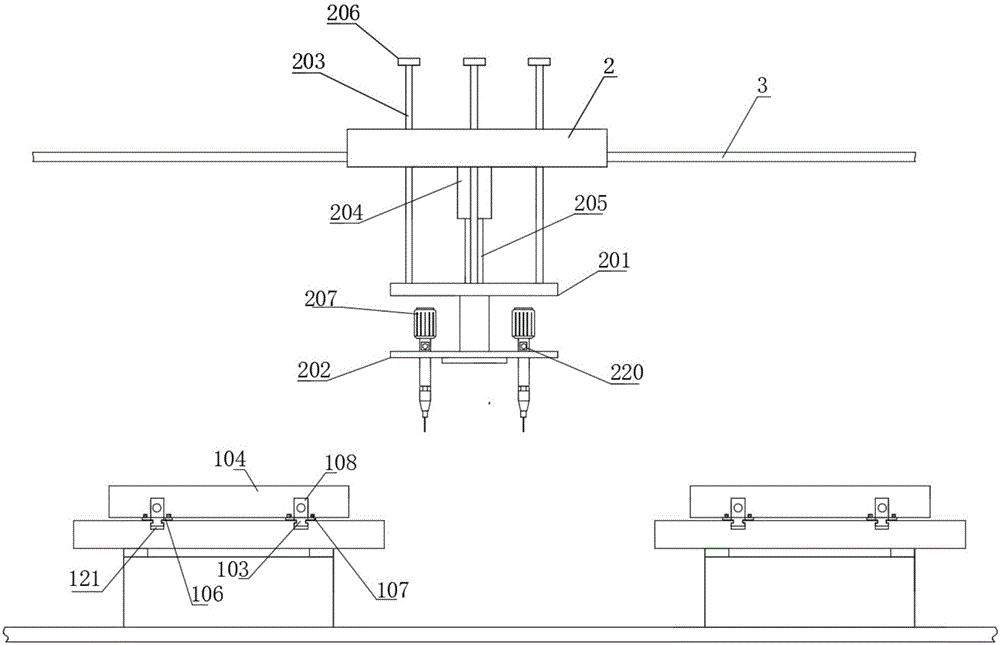

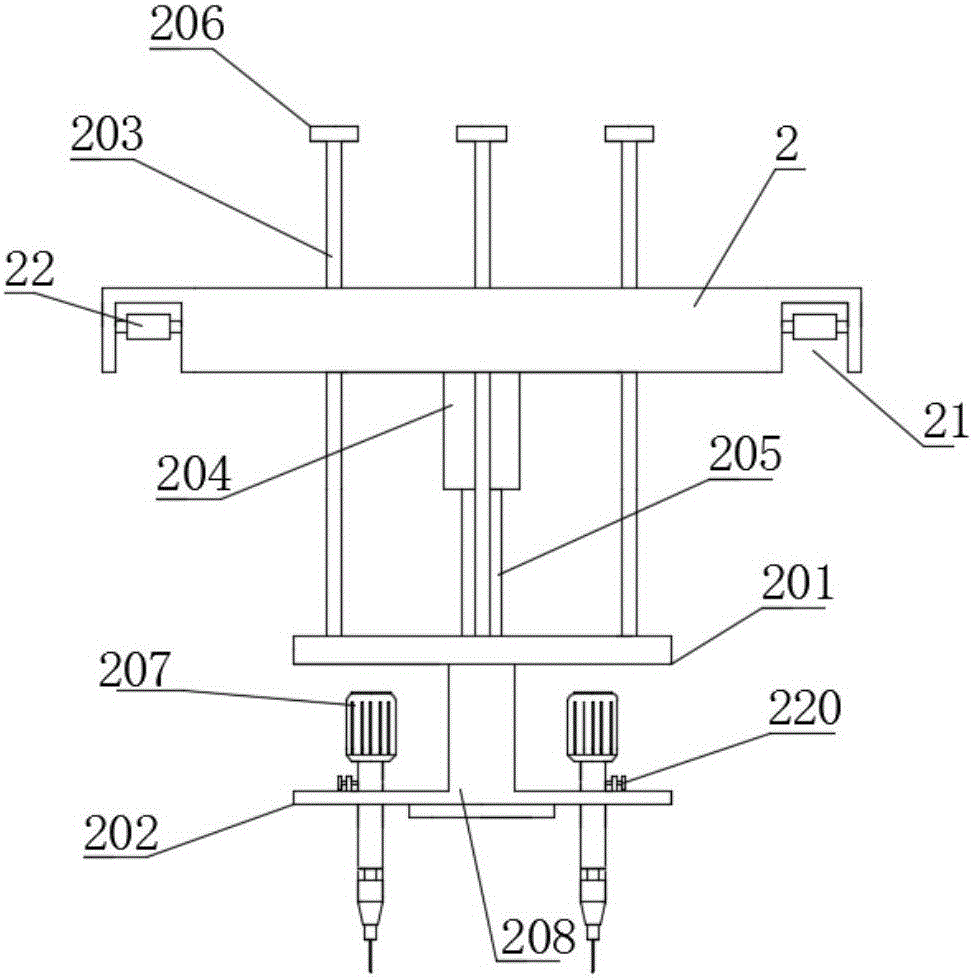

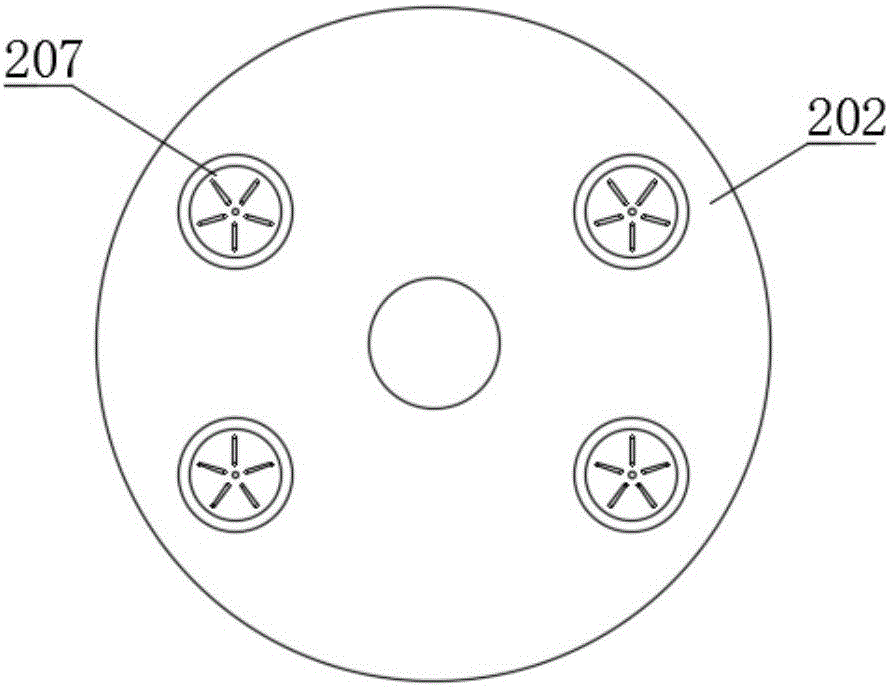

[0017] like Figure 1-6 As shown, this embodiment provides a turntable platform-type steel structure assembly equipment, including an operating platform, an assembly device, and a suspension rail; the suspension rail includes two parallel steel rails 3; the steel rails 3 are installed on a bracket or a wall Above; the assembly device includes a mounting plate 2, an upper mounting plate 201, a rotating plate 202, a sliding rod 203, a lifting column 204 and an electric screwdriver 207; the two ends of the bottom of the mounting plate 2 are respectively provided with upper concave chute 21 The chute 21 is provided with a plurality of rollers 22; the rollers 22 are movable and fixed on the side wall of the chute 21 through the wheel shaft; the assembly device is installed on the rail 3 through the rollers 22 on the mounting plate 2; The lifting column 204 is fixed on the bottom of the mounting plate 2, and its piston rod 205 is connected to the upper mounting plate 201; The lower...

Embodiment 2

[0019] like Figure 1-6 As shown, this embodiment provides a kind of steel structure assembly equipment. What is different from Embodiment 1 is that the operating platform includes slide rails and two clamping platforms movably installed on the slide rails; the clamping platform includes Base 101, table top 102 and two clamping mechanisms; the bottom of the base 101 is provided with a chute 111; it is installed on the slide rail through the chute 111; the table top 102 is arranged on the top of the base 101, the upper surface of the table top 102 There are two slideways 121 arranged in parallel, the cross-section of the slideway 121 is a convex structure, perpendicular to the direction of the slideway; two clamping mechanisms are arranged oppositely, and the clamping mechanism includes two sliders 103 , a bar splint 104 and a positioning bolt 107; the two sliders 103 are slidably installed in two slideways 121 respectively, and the cross section of the slider 103 is an I-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com