Silver steel composite plate sealing head manufacturing system and process

A technology of composite board and silver steel, which is applied in the head production system and its process field, can solve the problems that silver steel equipment cannot be reached, improve the production quality and electric energy conversion rate, reduce the influence of materials, and ensure accuracy and consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

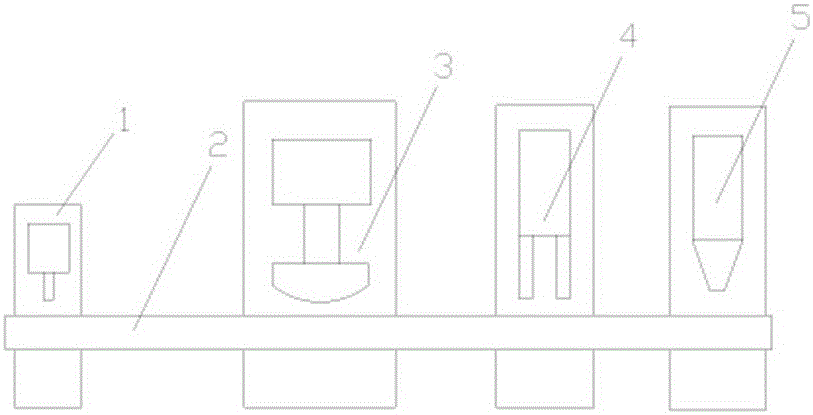

[0022] Such as figure 1 As shown, a silver-steel composite plate head production system includes a water jet cutting device, a transport mechanism, a stamping device, a transfer device and a cleaning device. The water jet cutting device is installed at one end of the transport mechanism, and the stamping device is installed at the transport The middle part of the mechanism, the transfer device is installed at the other end of the transport mechanism, and the cleaning equipment is installed on the upper part of the transfer device.

[0023] A kind of silver-steel composite board head manufacturing process, comprises the steps:

[0024] Step 1. Material cutting adopts a plane water jet without thermal influence to cut the silver-steel composite board;

[0025] Step 2. After the silver-steel composite board is cut, check the hardness, ferrite, bonding rate, and silver surface condition of the silver-steel composite board, and attach a protective film to the qualified silver-stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com