Horizontal drum for automatic turnip cutter

A radish machine, horizontal technology, applied in metal processing, etc., can solve the problems of manual feeding, inconvenient use, etc., and achieve the effect of continuous and stable output and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

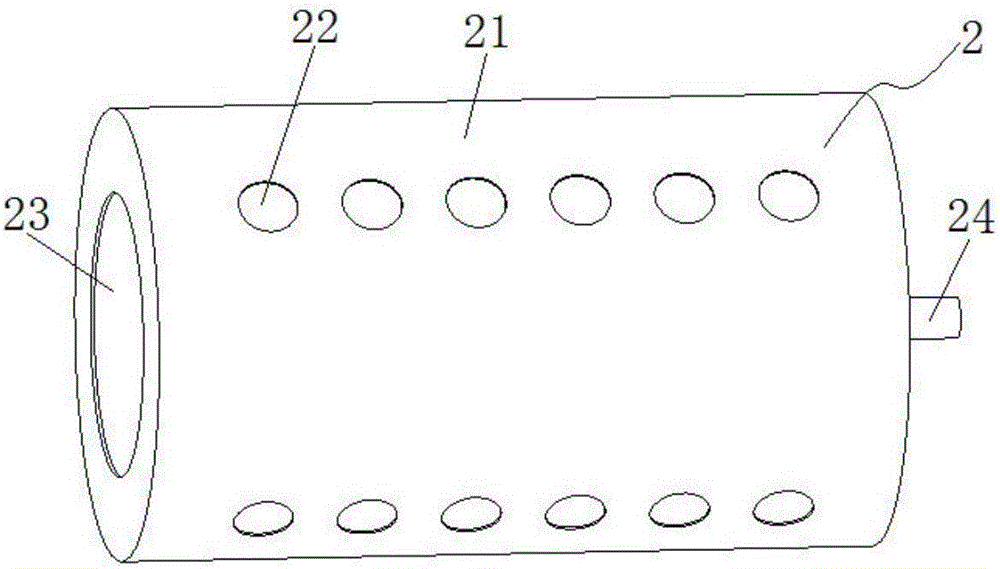

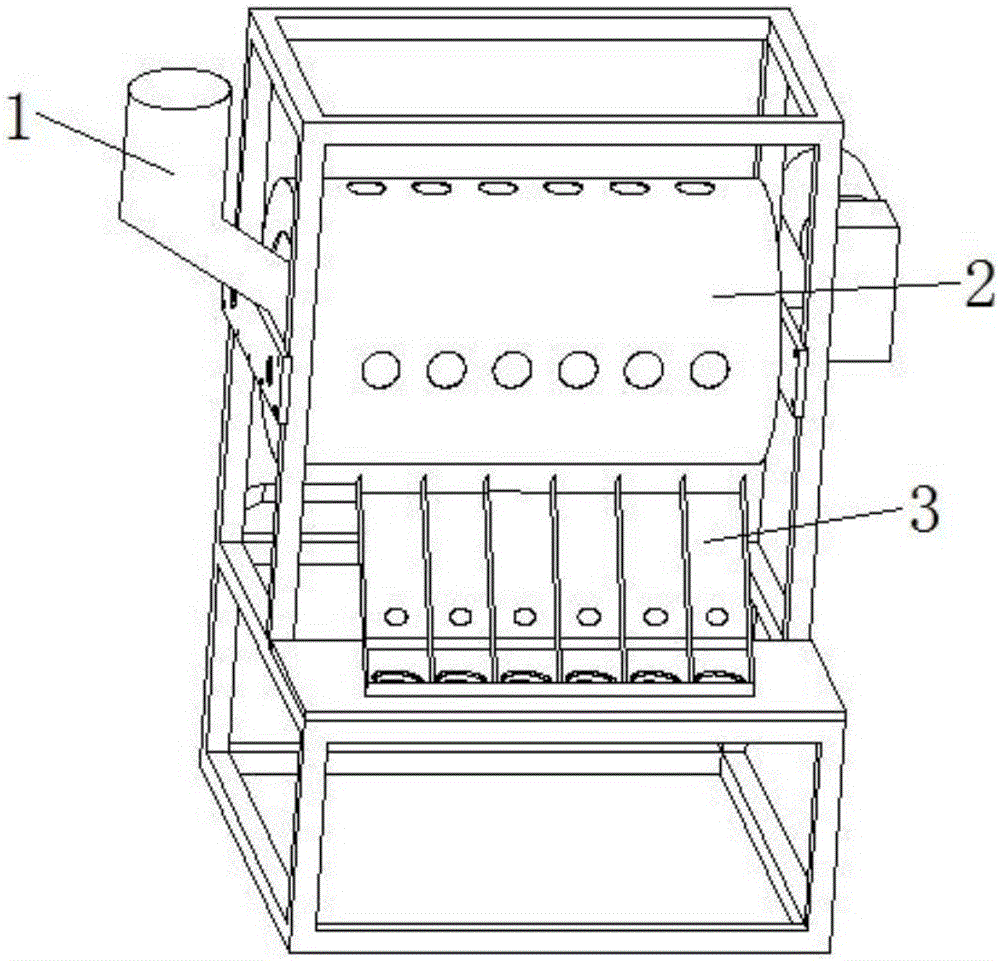

[0023] combine figure 1 , a kind of horizontal drum that is used for the automatic radish cutting machine of present embodiment, comprises horizontal barrel body 21, and one end surface of barrel body 21 is provided with feed port 23 for feeding radish, and the cylindrical surface of barrel body 21 More than one set of discharge ports 22 are provided in the circumferential direction for the discharge of radish, and each group of discharge ports 22 is arranged in multiple axial directions. Specifically, four groups of discharge ports 22 are arranged on the cylindrical surface of the barrel body 21 in the circumferential direction. The output is more continuous and stable. The barrel body 21 is also provided with a transmission part 24 for the driving mechanism to drive it to rotate. Preferably, the transmission part 24 is arranged on the other end surface of the barrel body 21 . It should be noted that, in this embodiment, if some outlets 22 need to be closed according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com