Manufacturing method of heat-insulation light-reflection shed cloth

A manufacturing method and shed cloth technology, applied in the field of shed cloth manufacturing, can solve difficult problems such as temperature stability in the shed, poor heat insulation and light insulation effect, and achieve good heat insulation and reflective effect, low production cost, The effect of high tent cloth strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

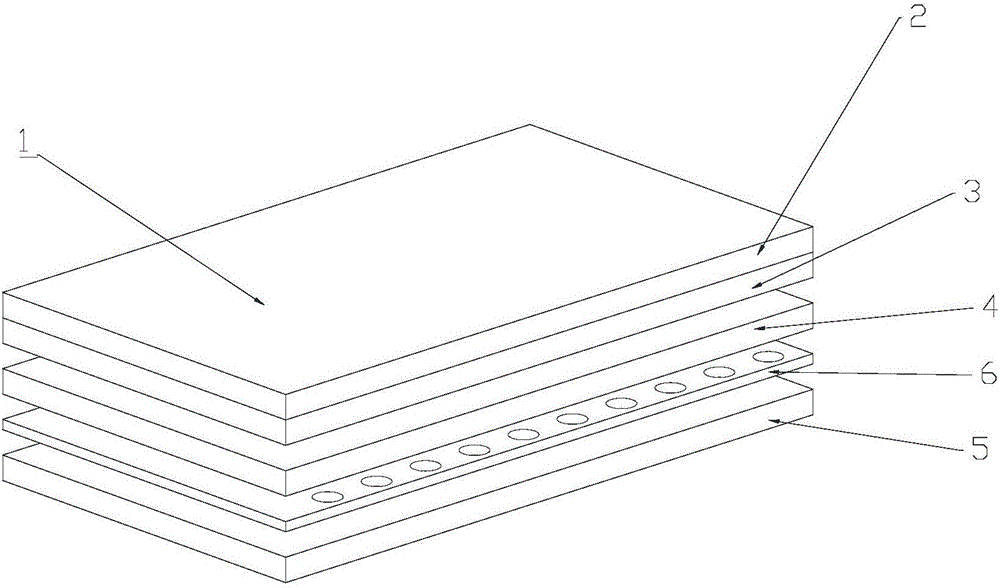

[0016] A method for manufacturing a heat-insulating and reflective tent cloth, comprising the following steps: placing an upper layer of PPC cloth 4 on a cloth laminating machine and heating it to 95°C, and uniformly coating a layer of melted hot melt Glue, the polyester layer 3 of the polyester aluminized film 1 and the upper PPC cloth 4 coated with hot melt adhesive are hot-pressed and bonded by a cloth laminating machine to form a double-layer composite cloth. After the lamination is completed, the double-layer composite cloth Take it out from the cloth laminating machine and cut it cold at room temperature to 60°C; put the lower layer of PPC cloth 5 on the cloth laminating machine and heat it to 95°C, and evenly coat a layer of melted PPC cloth on the upper surface of the lower layer of PPC cloth 5 Hot-melt glue, the grid-shaped polyester cloth 6 and the double-layer composite cloth are laid on the upper surface of the lower PPC cloth successively, wherein the lower surface...

Embodiment 2

[0020] A method for manufacturing a heat-insulating and reflective tent cloth, comprising the following steps: placing an upper layer of PPC cloth 4 on a cloth laminating machine and heating it to 100°C, and uniformly coating a layer of melted hot melt glue, the polyester layer of the polyester aluminized film 1 and the upper PPC cloth 4 coated with hot melt adhesive are hot-pressed and bonded by a cloth laminating machine to form a double-layer composite cloth. After the lamination is completed, the double-layer composite cloth is Take it out from the cloth laminating machine and cut it cold at room temperature to 70°C; place the lower layer of PPC cloth 5 on the cloth laminating machine and heat it to 100°C, and evenly coat a layer of melted heat on the upper surface of the lower layer of PPC cloth 5 Melt glue, lay grid-shaped polyester cloth 6 and double-layer composite cloth on the upper surface of lower PPC cloth 5 successively, wherein the lower surface of upper layer PPC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com