Light-reflecting heat-insulating coating for concrete tank truck, and preparation method and use method thereof

A technology for thermal insulation coatings and concrete, applied in reflective/signal coatings, radiation absorbing coatings, coatings, etc., can solve the problems of insufficient steel adhesion, no reflective thermal insulation effect, and paint peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A reflective and heat-insulating paint for concrete tank trucks is prepared by mixing the following components according to the proportions in the table:

[0056] project number of copies project number of copies space polymer emulsion 55 Nanoglass hollow microbeads 4 Boron Nitride 3 Hardener 1 Titanium dioxide 6 Anti-mildew and anti-algae agent 1 Super fine aluminum foil 1 water 45

[0057] Wherein, the space polymer emulsion is obtained by mixing silicone acrylic resin and pure acrylic resin according to a mass ratio of 3:1.

[0058] The titanium dioxide is selected from rutile titanium dioxide, and the particle size is 20 nm. The ultra-fine aluminum foil is obtained by pulverizing the aluminum foil with an ultra-fine pulverizer, and the pulverization fineness is 200 mesh. The particle size of the nanoglass hollow microbeads is 40 μm, and the bulk density of the nanoglass hollow microbeads is 120kg / m 3 . The cur...

Embodiment 2

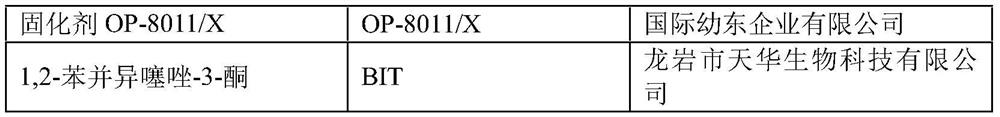

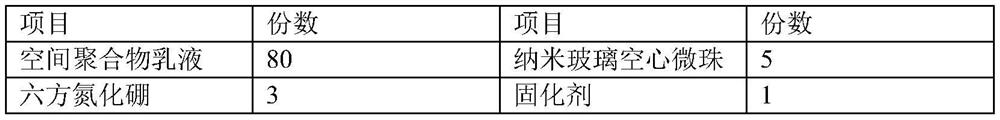

[0068] Compared with Example 1, this example is different in the formula ratio, preparation method and coating method of each component. A kind of reflective heat-insulating paint for concrete tank trucks of the present embodiment is prepared by mixing the following components according to the proportions in the table:

[0069]

[0070]

[0071] The titanium dioxide is selected from rutile titanium dioxide, and the particle size is 50 nm. The ultra-fine aluminum foil is obtained by crushing the aluminum foil with an ultra-fine pulverizer, and the pulverization fineness is 300 mesh. The particle size of the nanoglass hollow microbeads is 30 μm, and the bulk density of the nanoglass hollow microbeads is 120kg / m 3 . The curing agent is OP-8011 / X. 1,2-benzisothiazol-3-one was selected as the anti-fungal and anti-algae agent.

[0072] In the present embodiment, the preparation method of the reflective heat-insulating paint for concrete tank trucks comprises the following ...

Embodiment 3

[0081] Compared with Example 1, this example is different in the formula ratio, preparation method and coating method of each component. A kind of reflective heat-insulating paint for concrete tank trucks of the present embodiment is prepared by mixing the following components according to the proportions in the table:

[0082] project number of copies project number of copies space polymer emulsion 70 Nanoglass hollow microbeads 5 Hexagonal Boron Nitride 3 Hardener 2 Titanium dioxide 6 Anti-mildew and anti-algae agent 2 Super fine aluminum foil 1 water 20

[0083] The titanium dioxide is selected from rutile titanium dioxide, and the particle size is 25 nm. The ultra-fine aluminum foil is obtained by pulverizing the aluminum foil with an ultra-fine pulverizer, and the pulverization fineness is 500 mesh. The particle size of the nanoglass hollow microbeads is 30 μm, and the bulk density of the nanoglass hollow microbeads i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com