Polymerized gold-silicon insulator material with tracking and erosion resistant grade being 1A4.5 or higher, and preparation method and application thereof

A technology of resistance to tracking and electric corrosion, which is applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of poor electric corrosion resistance of silicone rubber composite insulators, improve working conditions and reduce compounding agents Loss, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

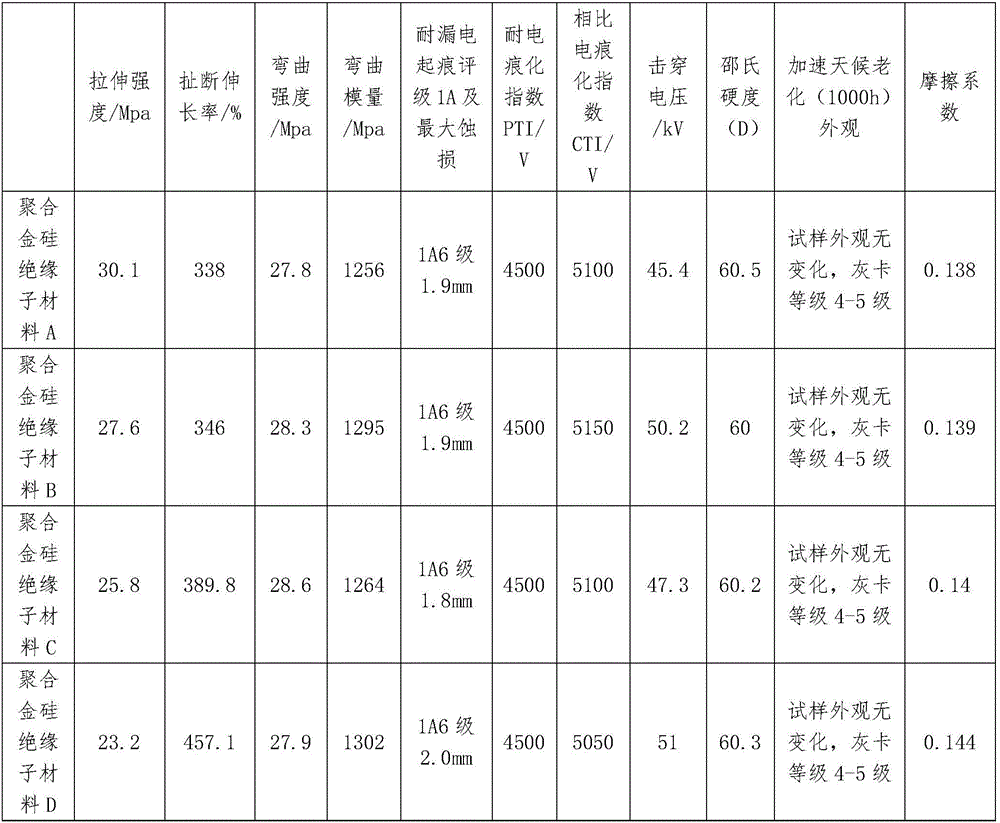

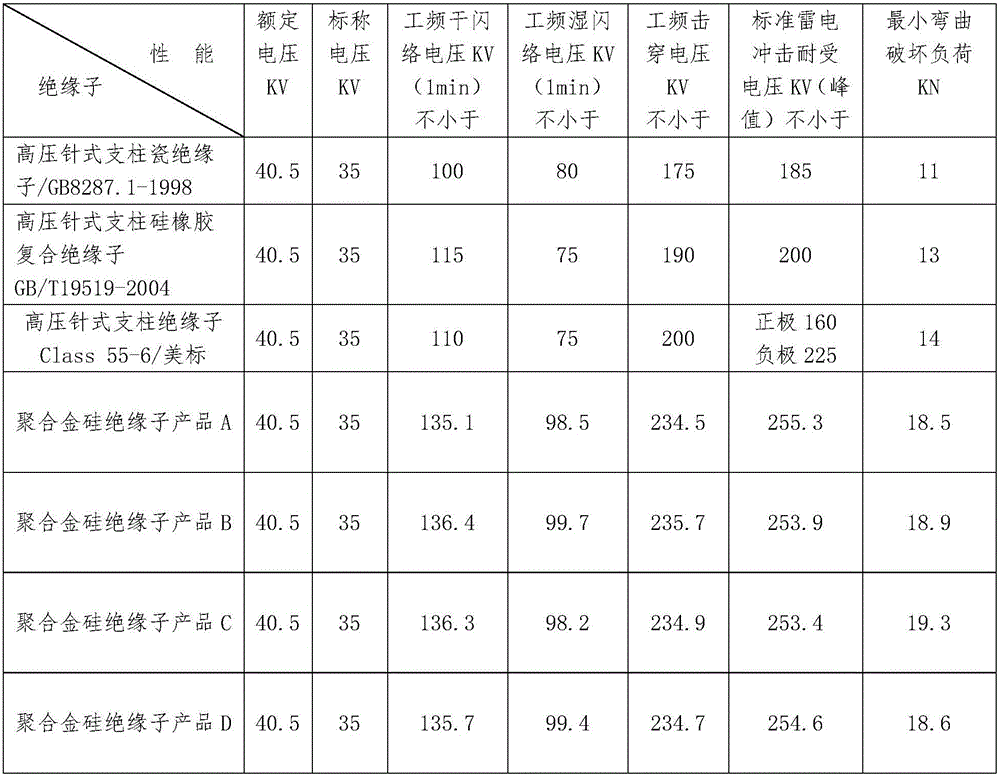

Embodiment 1

[0028] Preheat the internal mixer to 150°C, add 2.0kg of polypropylene with a molecular weight of 100,000 and 1.3kg of methyl silicone rubber with a molecular weight of 500,000, lower the top bolt, banbury at 0.5MPa and 150°C for 115s, and then Add 6.5kg of polyethylene with a molecular weight of 100,000, banbury at 0.5MPa and 150°C for 120s, raise the top bolt, and refine at 150°C for 115s. Adjust the roller distance of the open mill to 3.8mm, turn on the power switch, make the open mill run, open the circulating water valve, and then put the rubber discharged from the internal mixer into the upper roller of the open mixer, and wait for the temperature of the rubber to drop. When the temperature is below 110°C, add 0.2kg of aluminum hydroxide powder with a particle size of 8000-10000 mesh, cut the left and right knives twice, wait until the aluminum hydroxide powder is completely eaten, and the surface of the rubber material is relatively smooth, then cut off the rubber materi...

Embodiment 2

[0030] Preheat the internal mixer to 160°C, add 1.5kg of polypropylene with a molecular weight of 150,000 and 1.35kg of methyl silicone rubber with a molecular weight of 550,000, lower the top bolt, banbury at 0.6MPa and 160°C for 115s, and then Add 7.0kg of polyethylene with a molecular weight of 150,000 and banbury at 0.6MPa and 160°C for 115s, raise the top bolt, and refine at 160°C for 115s. Adjust the roller distance of the open mill to 3.8mm, turn on the power switch, make the open mill run, open the circulating water valve, and then put the rubber discharged from the internal mixer into the upper roller of the open mixer, and wait for the temperature of the rubber to drop. When the temperature is below 110°C, add 0.15 kg of aluminum hydroxide powder with a particle size of 8,000 to 10,000 meshes, cut the left and right knives twice, wait until the aluminum hydroxide powder is completely eaten, and the surface of the rubber is relatively smooth, then cut off the rubber. ...

Embodiment 3

[0032] Preheat the internal mixer to 150°C, add 1.0kg of polypropylene with a molecular weight of 200,000 and 1.38kg of methyl silicone rubber with a molecular weight of 600,000, lower the top bolt, banbury at 0.5MPa and 150°C for 120s, and then Add 7.5kg of polyethylene with a molecular weight of 200,000, banbury at 0.5MPa and 150°C for 110s, raise the top bolt, and refine at 150°C for 120s. Adjust the roller distance of the open mill to 3.8mm, turn on the power switch, make the open mill run, open the circulating water valve, and then put the rubber discharged from the internal mixer into the upper roller of the open mixer, and wait for the temperature of the rubber to drop. When the temperature is below 110°C, add 0.12 kg of aluminum hydroxide powder with a particle size of 8,000 to 10,000 meshes, cut the left and right knives twice, wait until the aluminum hydroxide powder is completely eaten in, and the surface of the rubber is relatively smooth, then cut off the rubber. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com