Lutetium aluminate green fluorescent powder and preparation method and application thereof

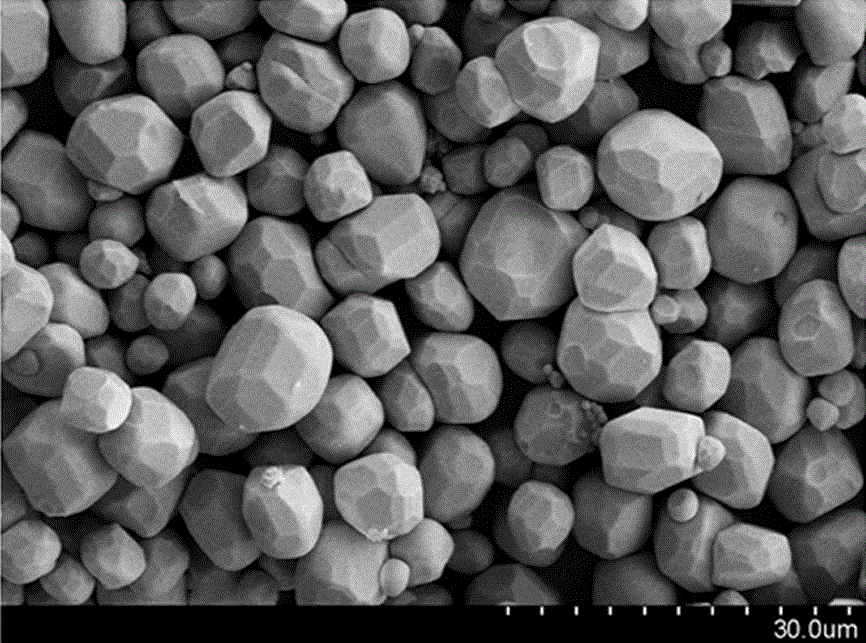

A technology of green fluorescent powder and lutetium aluminate, which is applied in chemical instruments and methods, light sources, luminescent materials, etc., can solve the problems of complex preparation methods, high energy consumption, and poor luminous brightness, and achieve high light conversion efficiency and high energy efficiency. The effect of low consumption and small average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

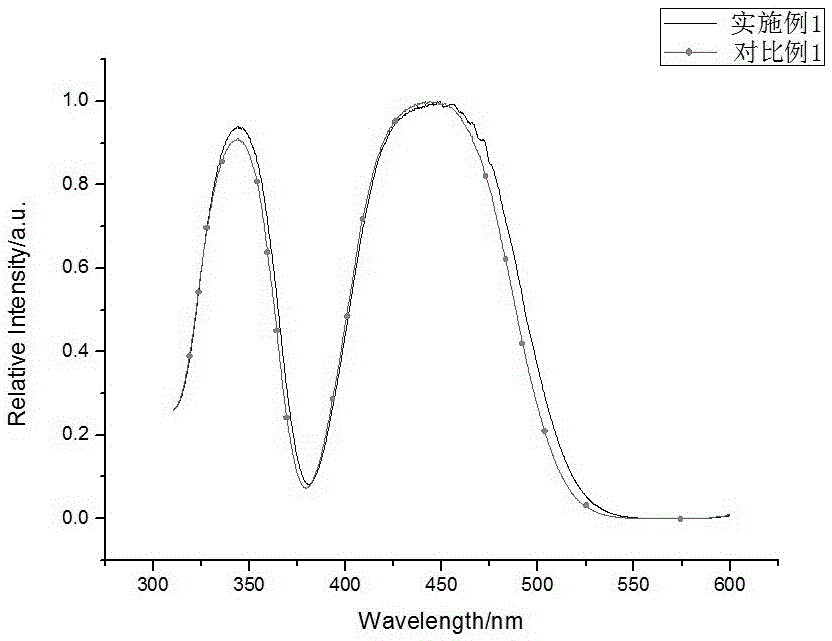

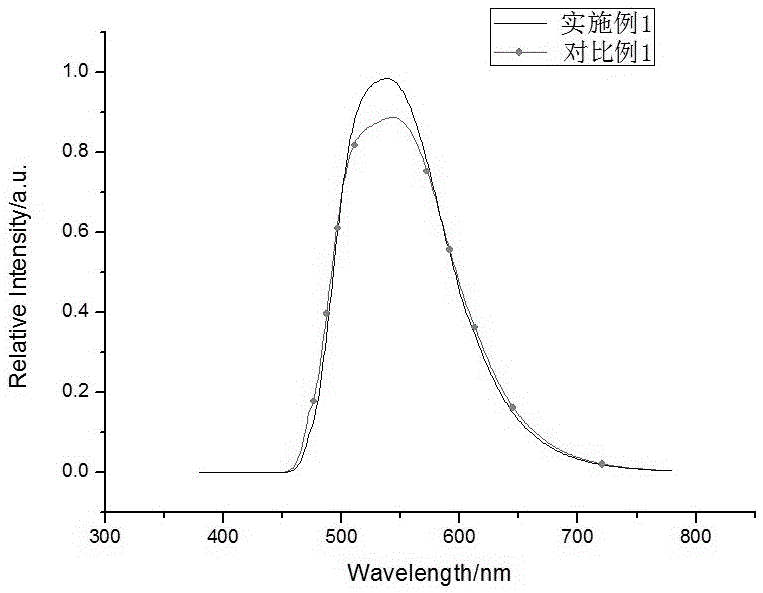

[0026] According to the chemical formula Ce 0.02 Lu 2.97 sc 0.01 al 5 o 12 The molar ratio of each element in the method weighs the oxide or carbonate raw material containing Ce, Lu, Sc, Al elements, then puts the said raw material in a mortar and grinds it, and mixes it evenly to obtain a mixture; add the raw material to the mixture Total mass 3% flux H 3 BO 3 , and mix evenly, and then put it in a corundum crucible; put the crucible in a pusher furnace, under the protection of a reducing atmosphere of nitrogen and hydrogen mixed gas, raise the temperature to 1430°C at a rate of 10°C / min, and keep it for 2h, then Naturally cool to room temperature to obtain crude phosphor powder; grind and sieve the crude phosphor powder, wash with hydrochloric acid solution with a concentration of 10% by mass, and dry at 80°C for 2 hours to obtain lutetium aluminate green phosphor Ce 0.02 Lu 2.97 sc 0.01 al 5 o 12 . Characterize the obtained product, the results are as follows: f...

Embodiment 2-12

[0031] The sintering temperature and sintering time in the phosphor powder preparation process were changed (see Table 1 for details), and the other raw materials and processes were the same as in Example 1. The relative performance of the prepared phosphor powder was tested, and the results are shown in Table 1.

[0032] Table 1:

[0033]

[0034]

[0035] It can be seen from Table 1 that when the sintering temperature is 1300-1500°C, the relative brightness of the lutetium aluminate phosphor reaches more than 100, which is better than that of Comparative Example 1. When the sintering temperature is lower than 1300°C or higher than 1500°C, the The brightness of the fluorescent powder is reduced. In addition, the sintering temperature is too high and the process conditions are more difficult to control. When the sintering temperature is 1430 ° C, the relative brightness of the phosphor is the highest, and the internal quantum efficiency of the QE test is the highest. The...

Embodiment 13-23

[0037] The amount and type of M were changed, the amount of Ce was changed (see Table 2 for details), other raw materials and processes were the same as in Example 1, and the relative performance of the prepared phosphor was tested, and the results are shown in Table 2.

[0038] Table 2:

[0039]

[0040] As can be seen from Table 2, the present invention effectively improves the relative brightness of the fluorescent powder by adding elements such as Ce and Sc. Within the specified range of dosing, the relative brightness of the fluorescent powder is higher than that of Comparative Example 1. When Ce and M When the incorporation amount is 2:1, the obtained phosphor has good comprehensive performance, relatively high brightness, and relatively high internal quantum efficiency in QE test, indicating that the light efficiency is relatively high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com