High-precision embedded part reinforcing and mounting device and method and purpose

A technology for installing devices and embedded parts, which is applied in the fields of construction, building structure, and building materials, and can solve problems such as the inability to meet the high-precision installation and construction requirements of embedded parts, affecting the fixed state, and damage to embedded parts. Achieve good application effect, improve installation efficiency, and easy construction and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

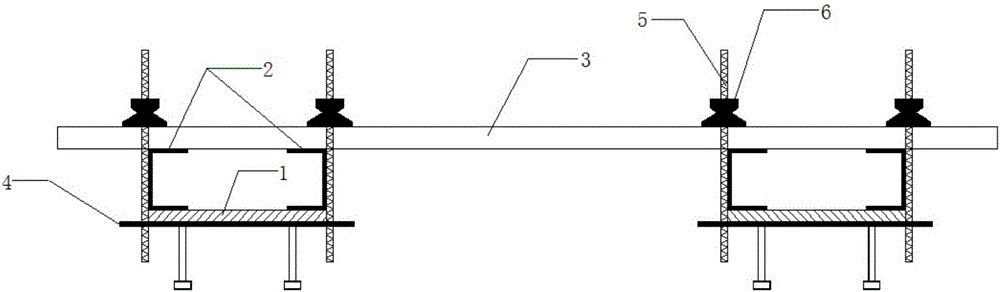

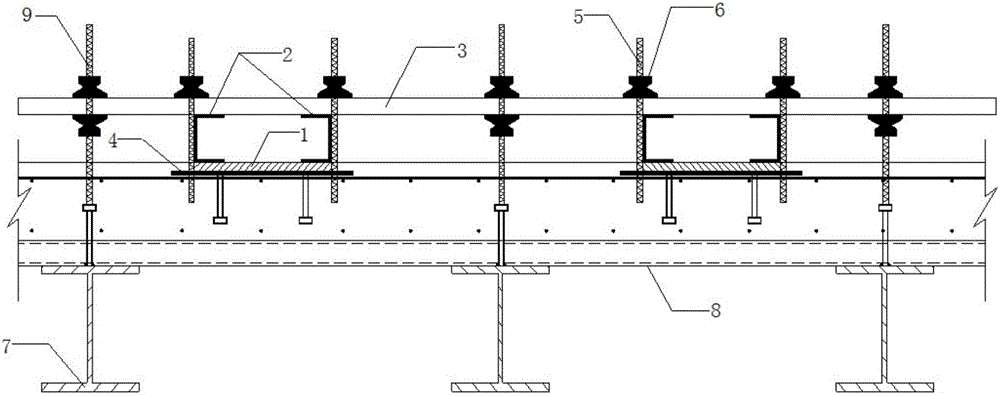

[0022] Such as figure 1 , figure 2 As shown, a high-precision embedded parts reinforcement installation device is first assembled into a figure 1 The fixed unit, the fixed unit is mainly composed of a supporting device, a connecting device, a limiting device, a locking device and a pressing device, wherein the limiting device is preferably two pull screws 5, and the connecting device is preferably two For steel pipes 3 parallel to each other, the supporting device is preferably two pieces of channel steel 2 , the locking device is preferably a wing nut 6 , and the supporting device is preferably a steel bar 4 . The specific installation method is as follows:

[0023] (1) Configure the embedded part fixing unit: set two symmetrical channel steels 2 above each embedded part 1, set steel bars 4 under the embedded part 1 for support, set the steel pipe above the channel steel 2, channel steel 2 and The embedded parts 1 are arranged between two opposite pull screws 5, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com