Totally-enclosed high-pressure shallow plug drilling device and application method thereof

A fully enclosed, shallow layer technology, applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problems of high transportation and relocation costs, increased production costs, high equipment costs, etc., to achieve significant economic benefits, safe and reliable work, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings, not to limit the protection scope of the present invention, and all improvements obtained by using the design idea of the present invention belong to the protection scope of the present invention.

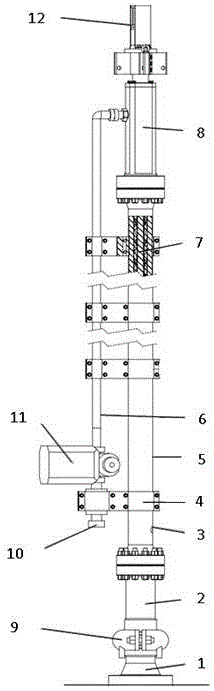

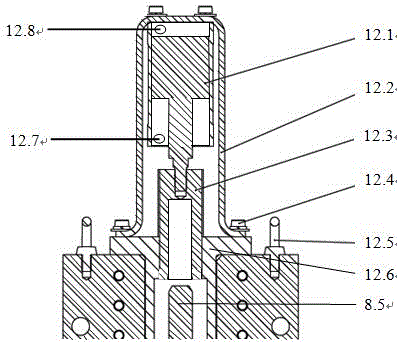

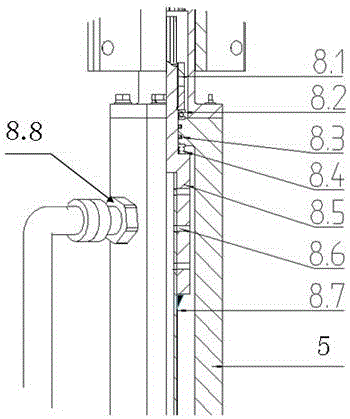

[0023] see figure 1 , the high-pressure shallow fully-enclosed drilling plug device includes a blowout preventer 5, the pipe body of the blowout preventer 5 is provided with a lower pressure port 3, and the inside of the pipe body is equipped with a piston assembly 7, and the upper end of the blowout preventer 5 is sequentially arranged from bottom to top It is connected with the upper pressure flange assembly 8 and the anti-rotation assembly 12, and the lower end is connected with the conversion sub-joint 2 and the anti-blowout sub-joint 1 sequentially from top to bottom, and the cylinder 12.1 in the anti-rotation assembly 12 passes through the spline sleeve 12.3 It is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com