Automatic telescopic operation platform for large-span large-variable-span-range variable coating steel form trolley

A steel formwork trolley and automatic telescopic technology, which is applied in the direction of fences, shaft linings, tunnel linings, etc., can solve the problems of variable cross-section shapes and fixed operating platforms that cannot meet the requirements for the use of steel formwork trolleys, and achieve large spans, The effect of high degree of automation and large span range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

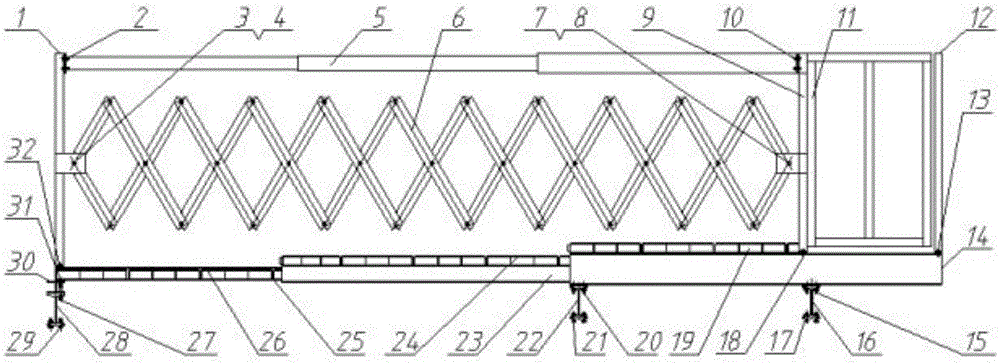

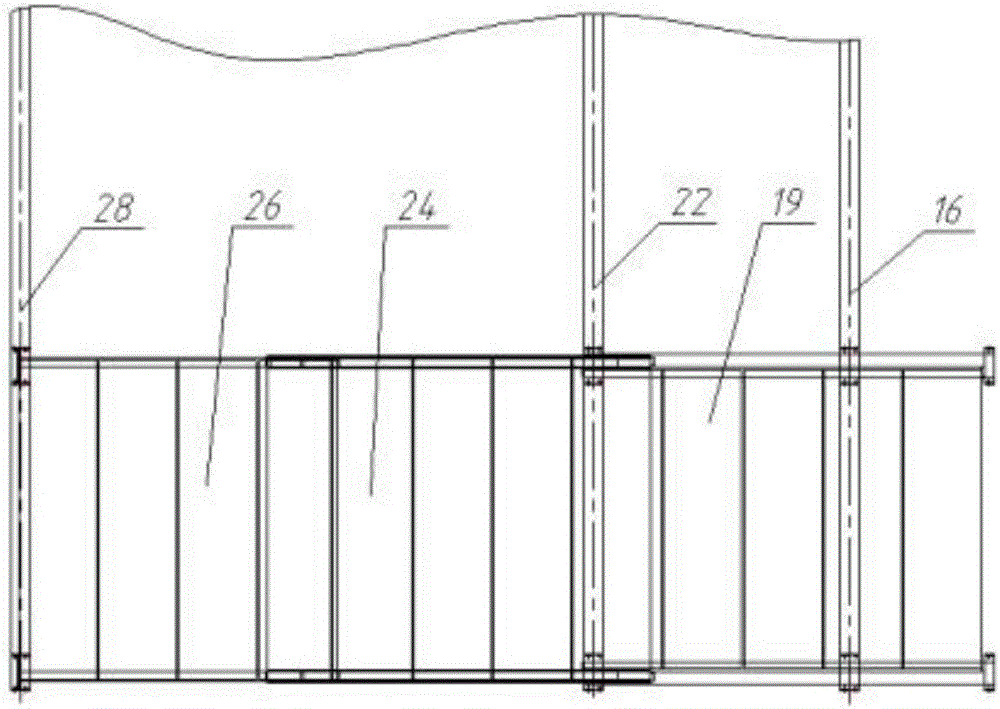

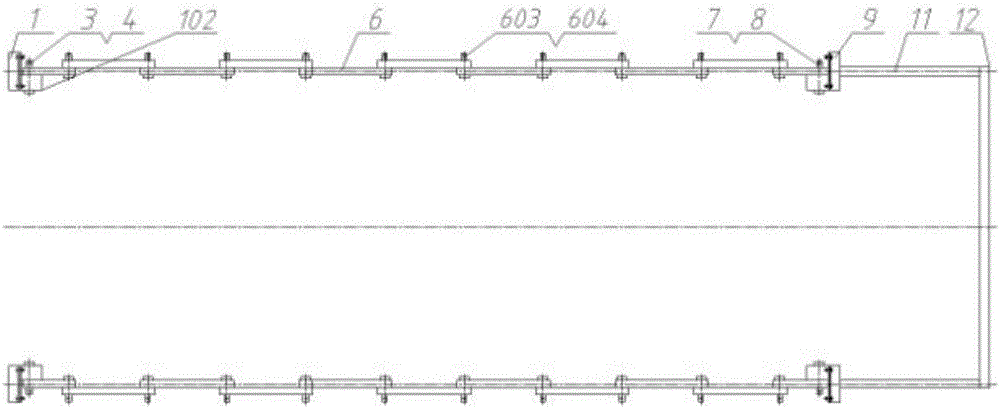

[0052] Such as Picture 1-1 As shown, a large-span and large-span range-variable automatic telescopic operation platform of the composite steel mold trolley of the present invention includes an end face telescopic guardrail 6, an inner end face telescopic guardrail column 1, an outer end face telescopic guardrail column 9, an end face Guardrail telescopic tube 5, end face telescopic guardrail inner connecting pin shaft I3, end face telescopic guardrail outer connecting pin shaft II7, inner end face telescopic guardrail column and end face guardrail telescopic tube connection bolt 2, end face guardrail telescopic tube and outer end face telescopic guardrail post connection Bolt 10, pedal frame inner sleeve 25, bolt 32 for connecting the pedal frame inner sleeve and the telescopic guardrail column on the inner end face, pedal frame outer cover 14, bolt 18 and door 11 for connecting the pedal frame outer cover and the telescopic guardrail column on the outer end face, wherein the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com