Stern ramp surface flatness detection method

A detection method and flatness technology, which is applied in the field of ship stern slides, can solve the problems of poor detection accuracy, high labor intensity, damage to stern slides, etc., and achieve the reduction of detection tooling materials, labor intensity, and accurate detection data high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

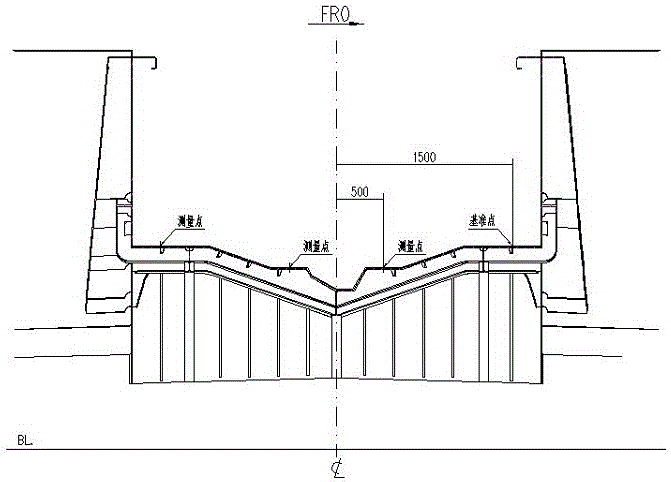

[0019] Such as figure 1 As shown, the detection method of the flatness of the stern slideway surface of the present invention comprises the following steps:

[0020] a. Establish a total station coordinate system based on the mid-longitudinal section of the stern section

[0021] Use the total station to measure the front and rear center points in the width direction of the stern slideway surface, and establish a total station coordinate system based on the mid-longitudinal section of the stern section, and the center point is the center point of the entrance and exit of the stern slideway;

[0022] b. Determine the reference point of the measurement

[0023] Mark the reference point at 1500mm from the center longitudinal section at the starboard side of the FRO rib on the stern slide surface, and measure this reference point with a total station. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com