Crescent windmill superstructure surface

A superstructure, windmill technology, applied in the field of optics and optoelectronics, to achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

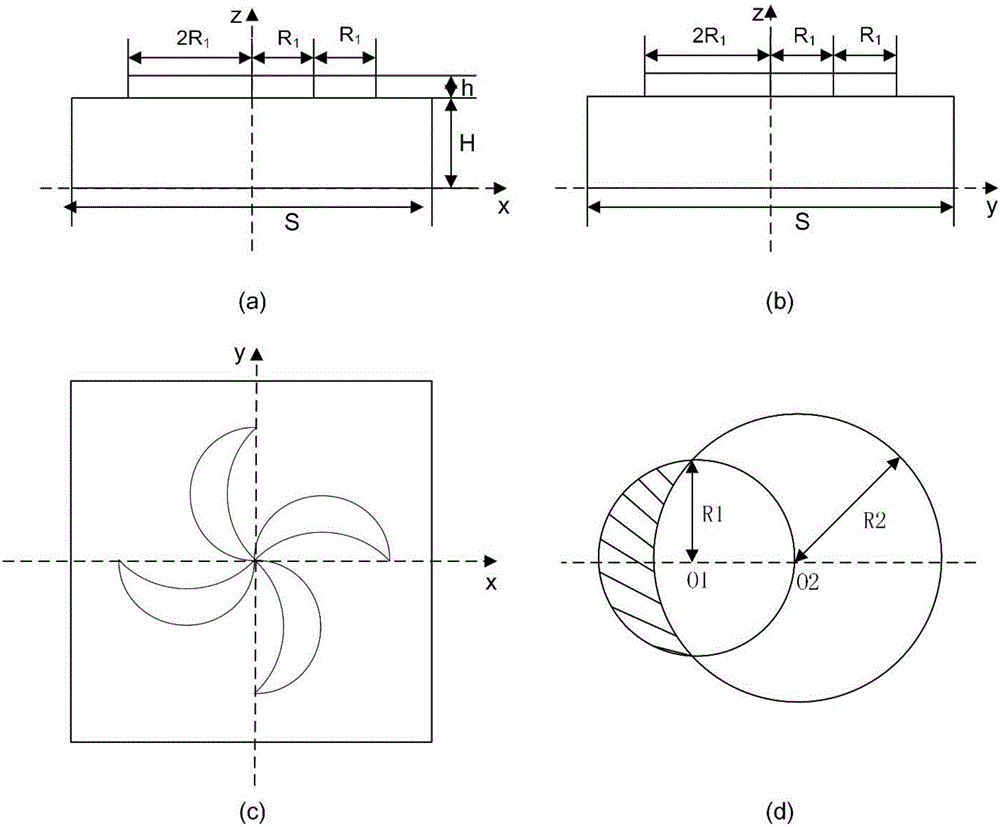

[0017] like figure 1 As shown, the superstructure surface of the crescent wind model provided by the present invention is composed of a dielectric substrate and a windmill-shaped metal structure. The structure is composed of crescent-shaped structures arranged at equal angles and in the same direction of rotation, and divides the angle of the plane circumference into N equal parts. The dielectric substrate is a cubic structure, and the substrate size is S×S×H, where S is the length and width of the substrate, and H is the thickness of the substrate. The geometric shape of the crescent-shaped fan blade can be obtained by intercepting two cylinders equivalently, and the section radii of cylinder 1 and cylinder 2 that intercept the crescent-shaped shape satisfy the relation

[0018]

[0019] where m is defined as the crescent factor, m≥2 and m is a positive integer, R 1 is the section radius of cylinder 1, R 2 is the section radius of the cylinder 2, and the section center ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Refractive index | aaaaa | aaaaa |

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com