Fault self-diagnosis system and method of substation inspection robot centralized monitoring system

A technology of inspection robot and self-diagnosis system, applied in testing/monitoring control system, general control system, control/regulation system, etc., can solve the problem of delaying fault recovery time, high complexity of manual positioning, time-consuming and labor-intensive, etc. To prevent the decline of control performance, reduce maintenance costs, and ensure the quality of diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0073] 1. The present invention is mainly used in the centralized monitoring system of the substation inspection robot, and provides a fault self-diagnosis method that can quickly locate the fault location of the substation inspection robot centralized monitoring system and provide timely reminders for fault handling.

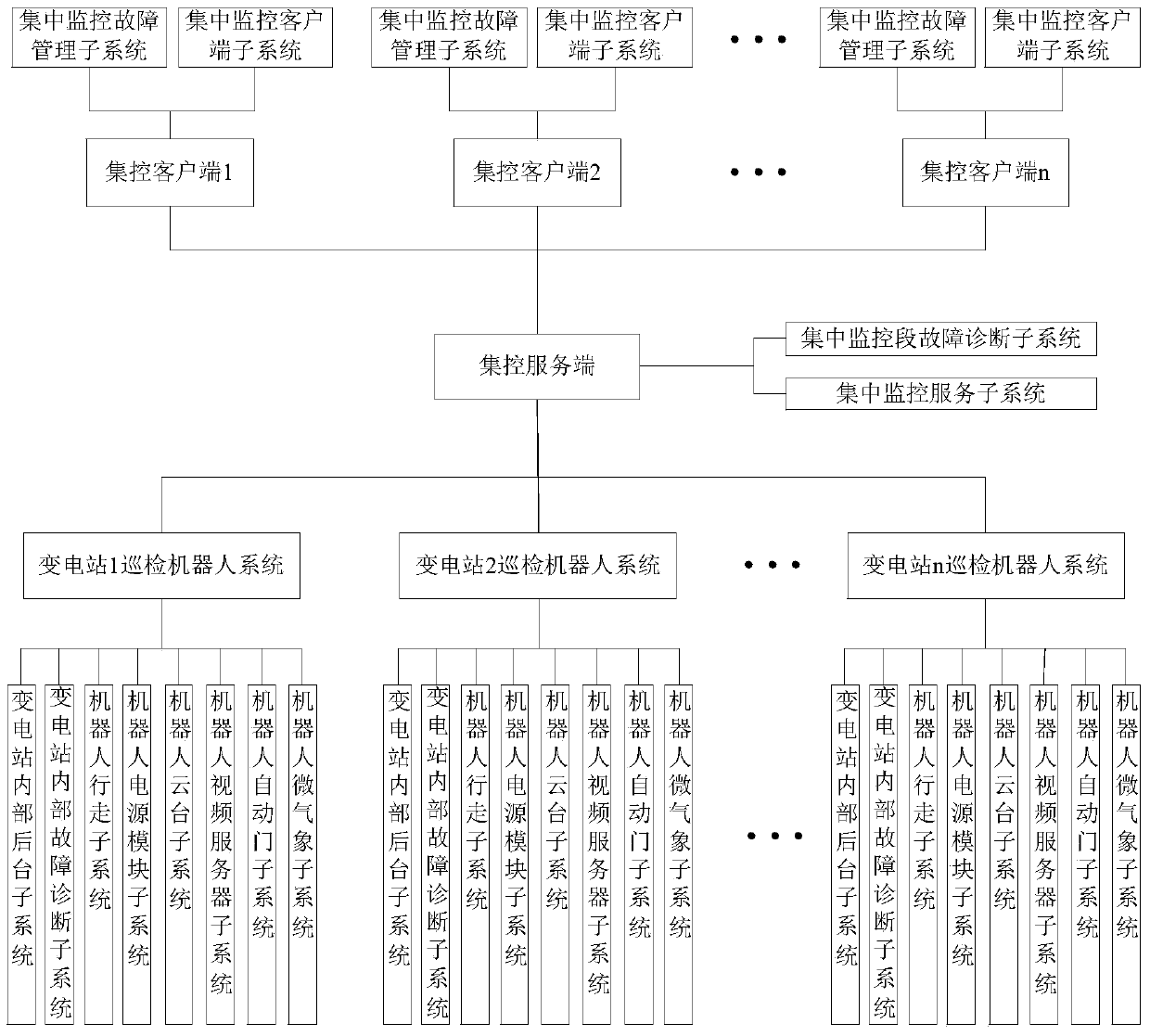

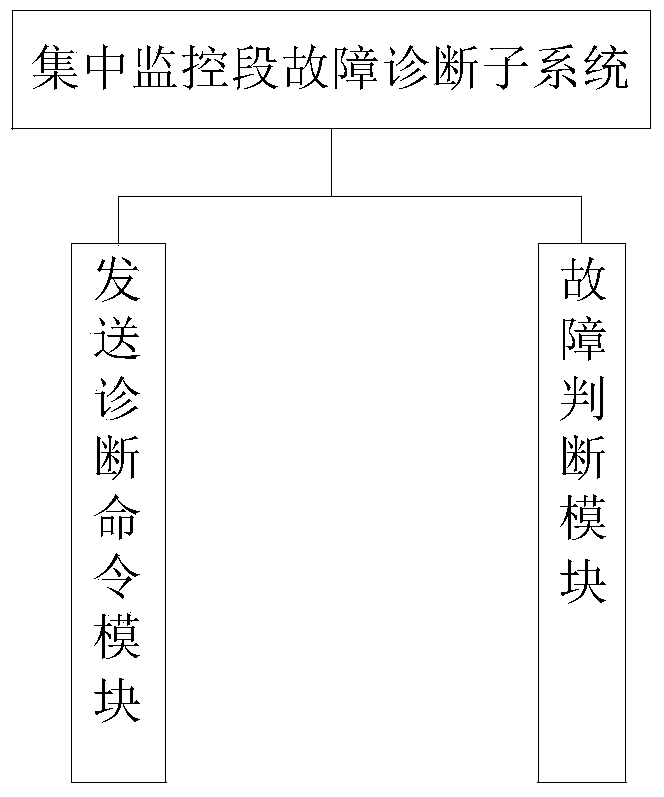

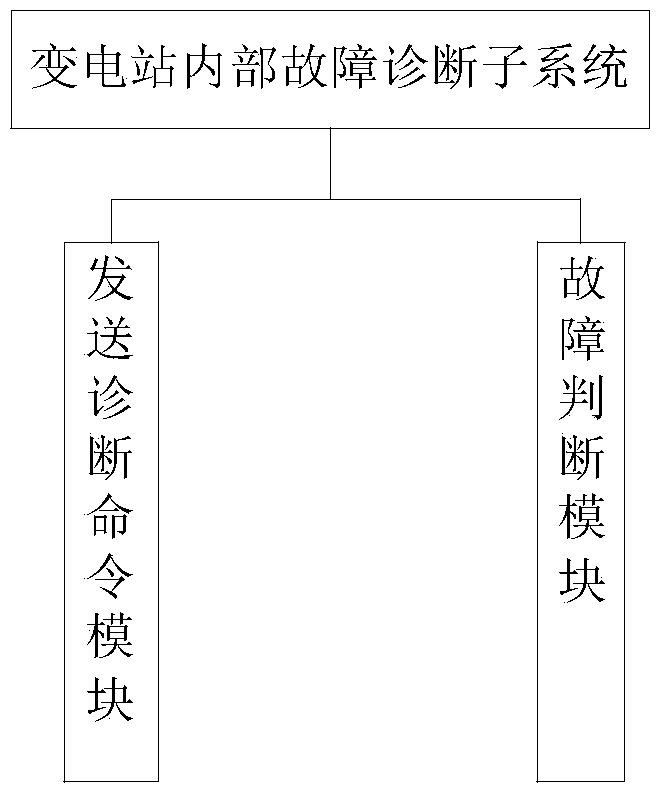

[0074] 2. Centralized monitoring system for inspection robots in substations, such as figure 1 As shown, the centralized monitoring system consists of a centralized monitoring server and a centralized monitoring client. The centralized monitoring server includes a centralized monitoring service subsystem and a centralized monitoring fault diagnosis subsystem, which is responsible for collecting data from multiple substations connected to the centralized monitoring system and providing an interface for downward judgment of fault points. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com