Machine learning-based industrial equipment fault preventive recognition method

A technology of industrial equipment and machine learning, applied in the detection of faulty computer hardware, using expert systems to detect faulty hardware, etc., can solve the problems of high skill requirements for maintenance personnel, loss of production and operation, and large cost of manpower and financial resources. To achieve accurate prediction results and prevent accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

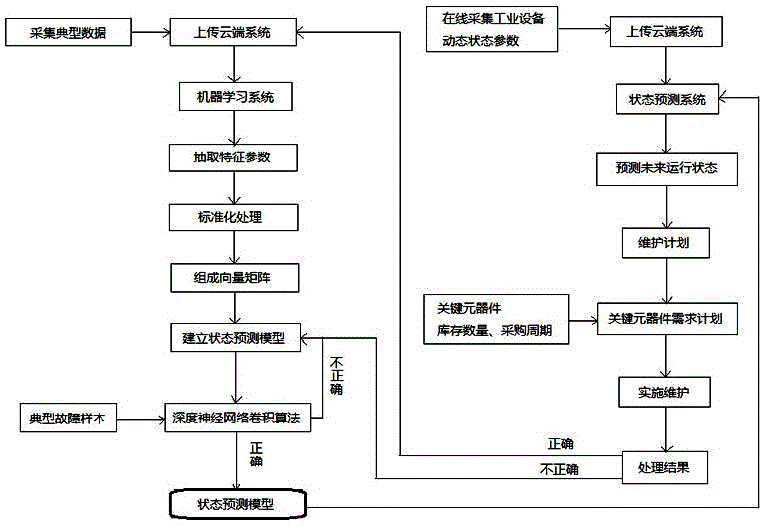

[0024] Such as figure 1 As shown, the implementation process of an embodiment of the present invention is as follows:

[0025] 1. Working steps of the machine learning module

[0026] Step 1: Collect typical data. The collected data include ① archive data of industrial equipment, including production date, factory performance index, installation date, installation area, special environment of the area, usage conditions, abnormal situations, etc.; ② typical failure cases of industrial equipment; ③ reliability model of industrial equipment , performance degradation data and curves, etc.; ④ reliability indicators of key components, typical failure cases of key components; ⑤ inventory quantity and procurement cycle of key components, etc.; ⑥ industrial equipment maintenance standard plan; The collection of these data is not one-time, but at any time.

[0027] Step 2: Upload cloud system. Upload the data collected in step 1 to the cloud system.

[0028] Step 3: Machine Learnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com