Intelligent manufacturing special network data acquisition scheduling system

A technology of intelligent manufacturing and data collection, applied in transmission systems, electrical components, etc., can solve problems such as slow deployment, slow upload speed, and poor security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

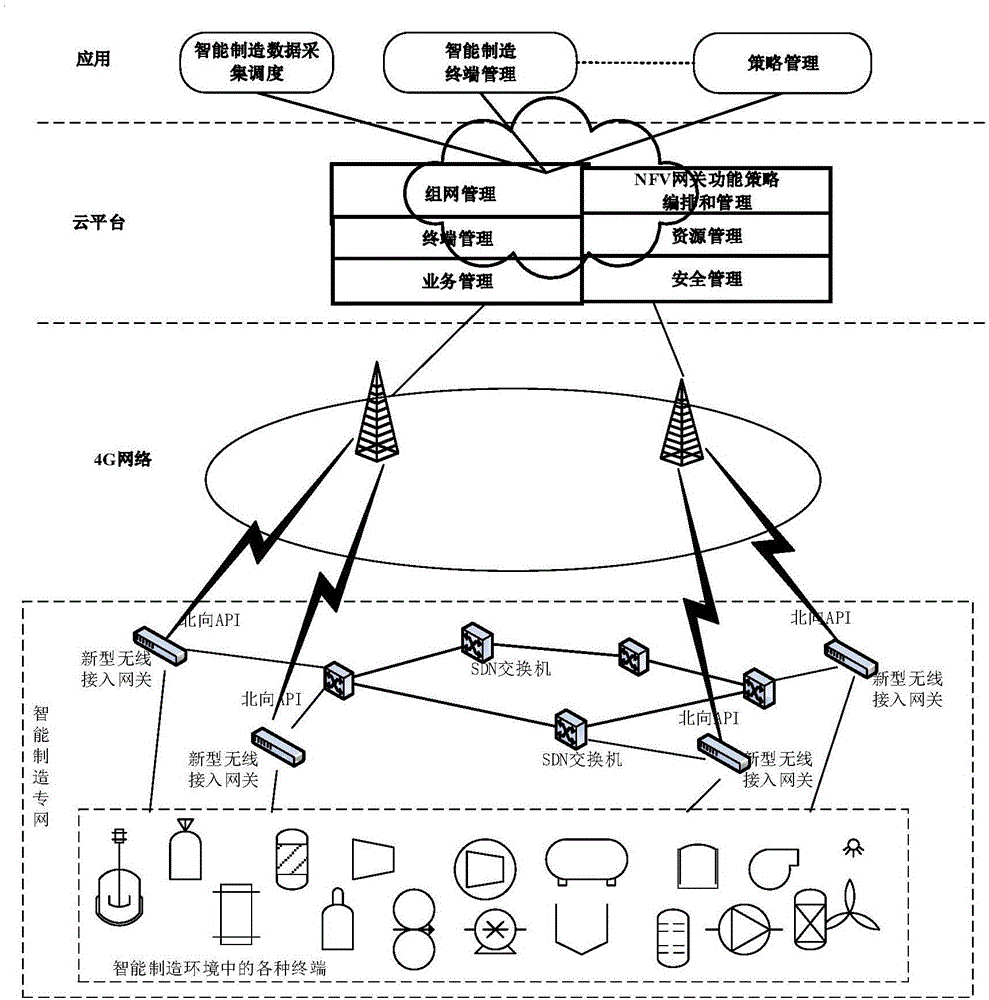

[0037] 1. Manufacturing private network data collection and scheduling system based on SDN and NFV

[0038] The architecture of the manufacturing private network data collection and scheduling system based on SDN and NFV proposed by the present invention is as follows: figure 1 As shown, it includes five parts: the internal network connecting the manufacturing equipment within the enterprise, the 4G-based wireless access network, the new wireless access gateway connecting the internal network and the external network, the cloud platform responsible for the centralized dispatching and management of the network, and the intelligent manufacturing center. various applications. The organic coordination of these five parts has built a 4G dedicated line intelligent dispatching prototype system for intelligent manufacturing, which realizes functions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com