Electric heater and preparation method thereof

A heater and electric heating element technology, applied in the direction of electric heating devices, ohmic resistance heating, ohmic resistance heating parts, etc., can solve the problems of low heat transfer efficiency of PTC electric heaters, low heat transfer efficiency of electric heaters, and The improvement of thermal efficiency is limited, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

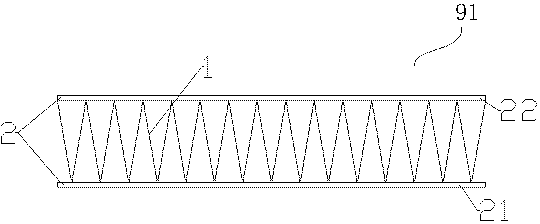

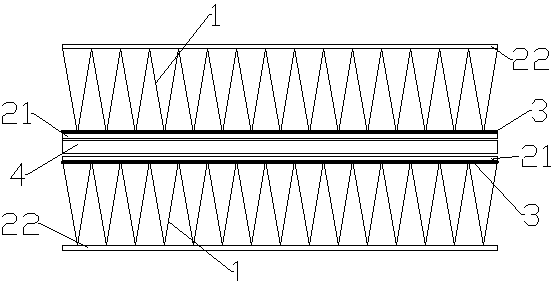

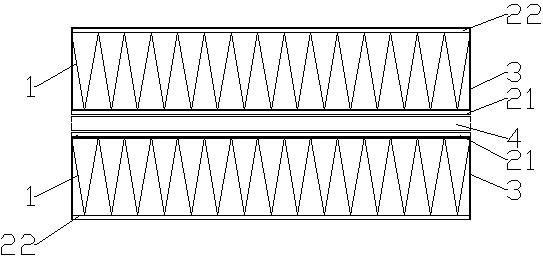

[0109] Such as figure 1 As shown, it is a schematic diagram of an aluminum heat sink 9 (or heat dissipation fin, or heat dissipation element, or aluminum heat dissipation strip, or aluminum strip) provided by the present invention. The heat sink 9 in this embodiment is a heat sink 91 composed of a group of fins 1 and side plates 2 located on both sides of the fins 1 . Such as figure 2 As shown, the heat sink 91 is provided with an insulating layer 3 on the surface attached to the PTC heating element 6 (that is, outside the bottom plate 21 ). That is, an insulating layer 3 is provided between the heat sink 91 and the PTC electric heating element 6 , so that the surface of the heat sink 91 that is not in contact with the PTC electric heating element 6 is not charged.

[0110] Such as image 3 As shown, it is a schematic diagram of a PTC heating element 6 (or PTC electrode strip assembly) provided by the present invention. The upper and lower sides of the PTC element 4 are re...

Embodiment 2

[0119] refer to Figure 8 , is a schematic structural diagram of the heat sink in Embodiment 2 of the present invention. As shown in the figure, the heat sink 9 of this embodiment is another kind of heat sink 92, and the heat sink 92 is composed of the fin 1 and the side plate 2 (ie, the top plate 22) on one side, that is, the heat sink 92 does not include Bottom plate 21. Such as Figure 9 As shown, the side plate 2 on the other side (i.e. the bottom plate 21) is used as the electrode sheet 5, and an insulating layer 3 is provided on the outside of the electrode sheet 5, and then the Figure 8 The heat sink 92 shown is bonded to the outside of the electrode sheet 5 .

[0120] The electric heater of this embodiment can be realized in the following way: two groups such as Figure 9 The components shown are bonded to both sides of several PTC elements 4 to form the electric heater of the present invention. An insulating layer 3 is provided between the heat sink 92 and the P...

Embodiment 3

[0127] refer to Figure 11 , is a schematic diagram of the structure of the heat sink and the external insulating layer in the third embodiment of the present invention, which is as in figure 1 The shown heat sink 91 is provided with an insulating layer 3 except for the surface attached to the PTC element 4 . As shown in the figure, the heat sink includes fins 1 and side plates 2 arranged on both sides; Both the outer side and both sides are insulated so as to obtain the insulating layer 3 as shown in the figure. That is, an insulating layer 3 is provided on the heat sink 91 at a portion not in contact with the PTC element 4 , so that the surface of the heat sink 91 not in contact with the PTC element 4 is electrically insulated or not charged. In this embodiment, the bottom plate 21 serves as an electrode sheet at the same time.

[0128] In this embodiment, the setting method of the insulating layer 3 can be: two cooling fins 91 are arranged on both sides of some PTC eleme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com