Ash gun with water injecting port

A technology of soot blower and water spray, applied in the field of soot blower, can solve problems such as affecting the health of operators, affecting the air, and spreading dust, and achieves the effect of wide spraying range, preventing dust spreading, and ensuring physical health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

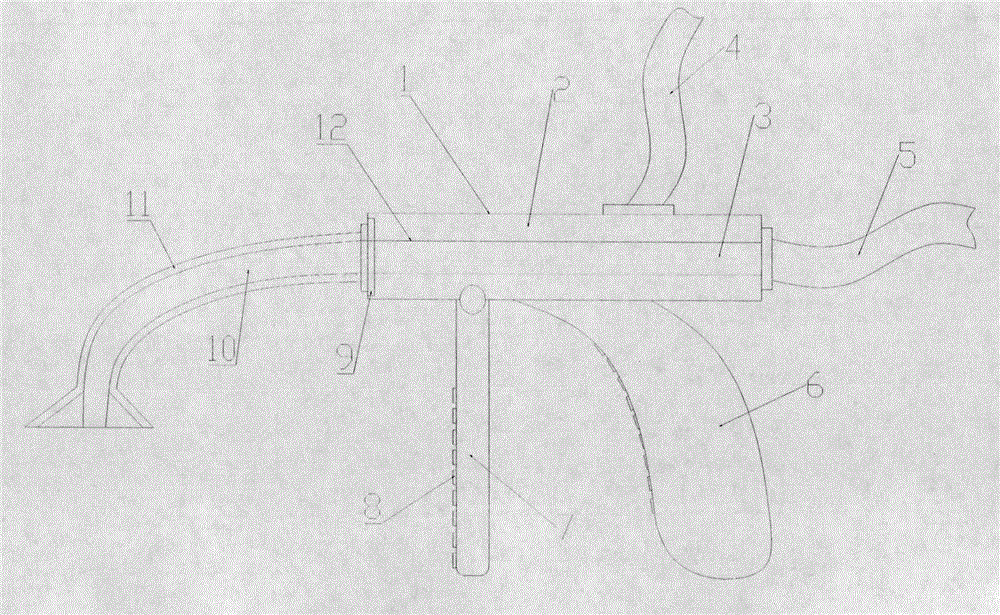

[0018] Such as figure 1 As shown, the present invention discloses a soot blowing gun with a spray nozzle, which includes a soot blowing gun body 1, an injection device connected to one end of the soot blowing gun body 1 and an actuator at the lower end.

[0019] The soot blower body 1 is hollow, and a gas channel 3 and a liquid channel 2 are separated by a circular columnar partition 12 inside; the middle part of one end of the soot blower body 1 is connected to the air inlet pipe 5, and the side wall is connected to a water inlet pipe 4, A valve 9 is arranged at one end away from the water inlet pipe 4 .

[0020] The injection device includes an air outlet pipe 10 and an annular water outlet pipe 11 arranged outside the air outlet pipe 10. The end of the air outlet pipe 10 is closely connected to the end of the partition plate 12, and is detachably connected to the end of the soot blowing gun body 1, away from the connection. One side ends in a trumpet shape.

[0021] The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com