Quantitative detection device and method for iron loss of motor based on leading out of heat

A technology of heat extraction and quantitative detection, which is used in measurement devices, measurement of electrical variables, and motor-generator testing. Data-reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

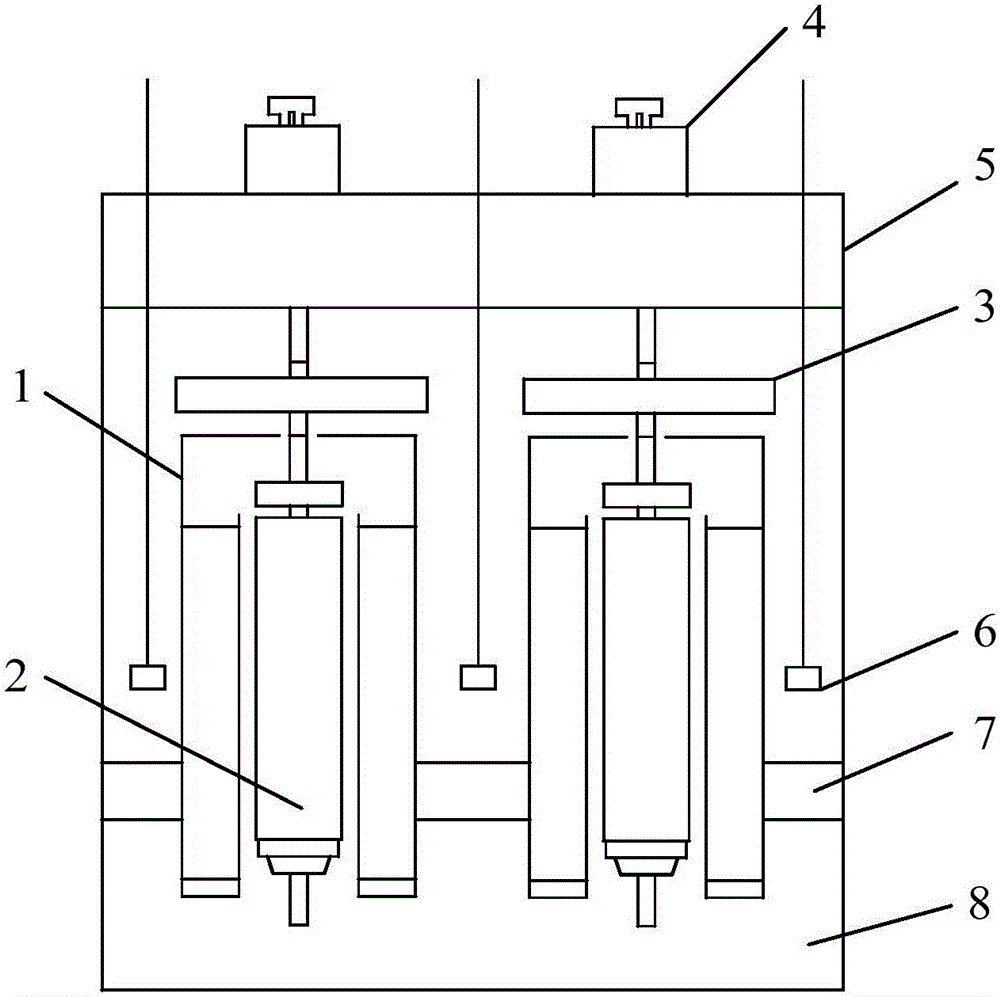

[0032] Such as figure 1 As shown, a motor iron loss quantitative detection device based on heat derivation includes a thermal insulation container 5, a heat-conducting medium 8, an excitation unit, a motor body 1 to be tested and a temperature measuring element 6, and the heat-conducting medium 8 is a fluid heat-conducting medium 8 are evenly distributed in the thermal insulation container 5, and the excitation unit and the temperature measuring element 6 are fixed in the thermal insulation container, wherein the thermal insulation container 5 is used to reduce the heat exchange between the system and the external environment. The excitation unit includes a magnetizing rotor 2 of the motor to be tested, a stirring blade 3 and a drag motor 4 for stirring the heat-conducting medium 8, and the stirring blade 3 and the drag motor 4 are respectively connected to the On the rotating shaft of the magnetized rotor 2 of the motor to be tested described above. In addition, a cage 7 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com