Pure-soil nutritional bowl production line and production method

A nutrient bowl and production line technology, applied in planting substrates, botanical equipment and methods, culture medium, etc., can solve the problems of insufficient strength, increase the cost of nutrition bowls, easy deformation, etc., and achieve reasonable structural design, high environmental protection value, strong strength. The effect of promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

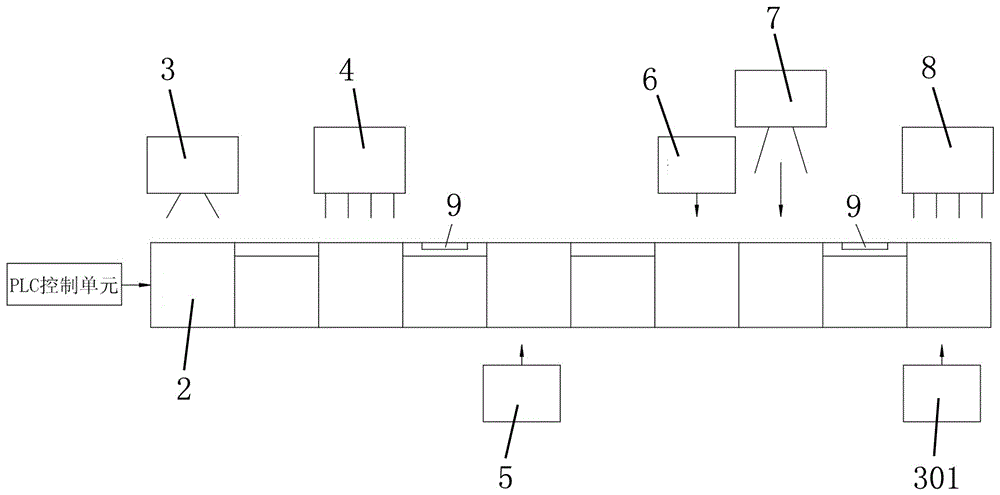

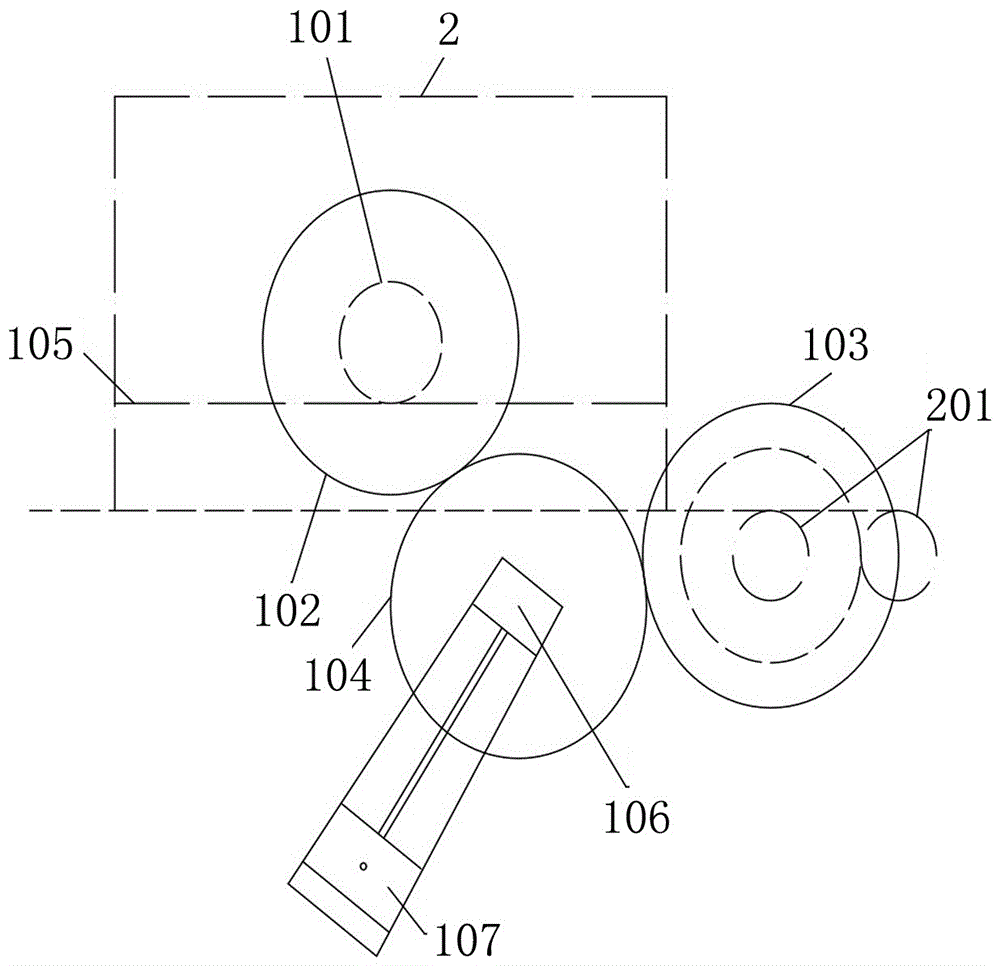

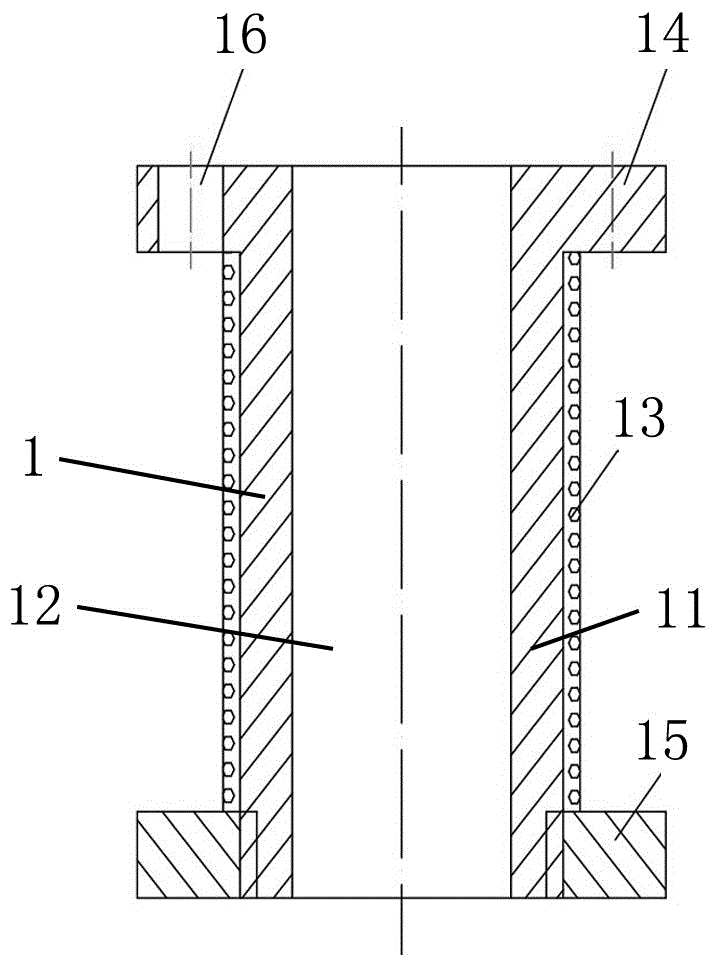

[0030] Such as figure 1 and image 3 As shown, the production line of the pure soil nutrition bowl of the present embodiment comprises frame and the mold case 2 that some nutrition bowl molds 1 are housed, and the mold box 2 has the through hole that runs through up and down, and some nutrition bowl molds 1 are evenly distributed in this passage. In the hole, the nutritional bowl mold 1 includes a mold body 11 and a heating assembly 13. The mold body 11 has a through inner hole 12, and the heating assembly 13 is arranged around the periphery of the through inner hole 12. Station, solidification molding station, sowing station, soil covering station and molding station, soil injection station, compacting soil nesting station, curing molding station, sowing station, soil covering station and molding station through The transmission me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com