Pressing plate type greenhouse framework and light and stable solar greenhouse

A technology of solar greenhouse and pressing plate, applied in the field of solar greenhouse, can solve the problems of large area of rear wall and steel skeleton, decreased land utilization rate, complicated engineering, etc., and achieves the effects of light weight, simple structure and simple construction technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

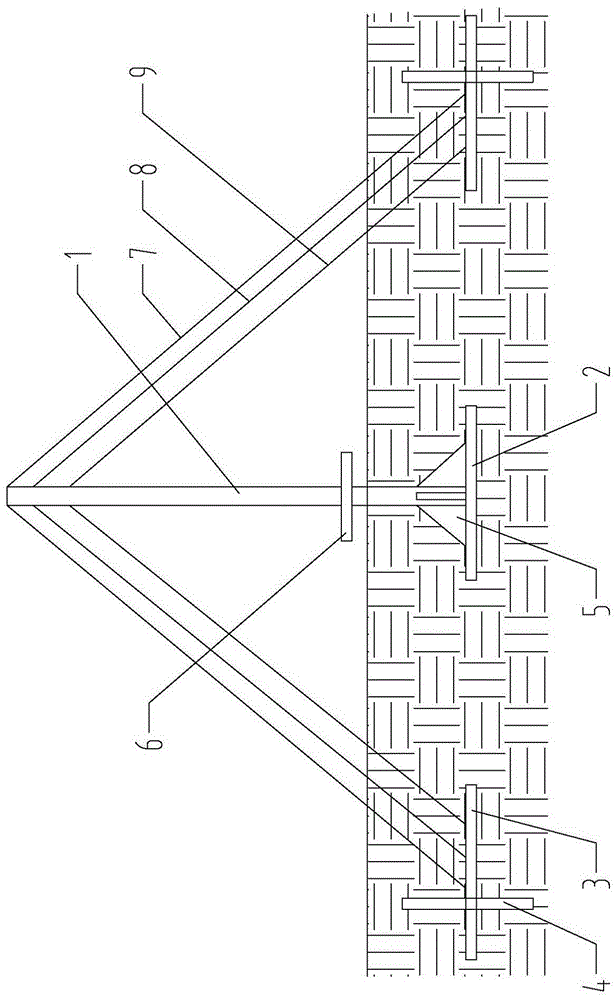

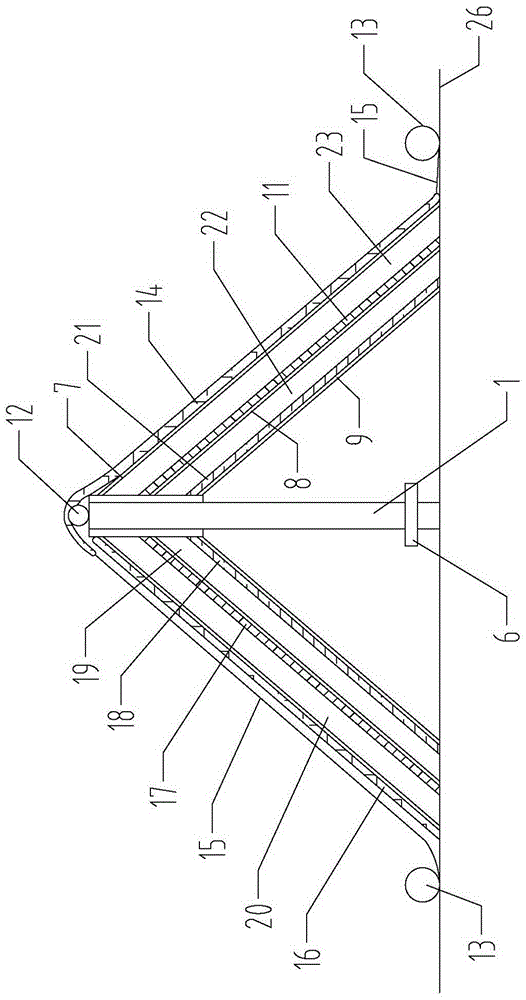

[0026] Example 1, such as figure 1 As shown, the frame of the press plate greenhouse includes a central column 1, a column press plate 2, and a wing press plate 3; the bottom of the center column 1 is fixed together with the center of the upper end surface of the horizontal column press plate 2; each side of the column press plate 2 is provided with a horizontally placed The wing pressing plate 3 is connected with at least one pull rod or at least one straight stay cable between the center of the upper end surface of the wing pressing plate 3 and the top of the central column 1 .

[0027] During use, the foundation is excavated at the position corresponding to the column pressing plate 2 and the wing pressing plate 3 on both sides, without concrete pouring, directly the column pressing plate 2 and the wing pressing plate 3 are buried one meter to three meters below the ground 26, and compacted with soil. Yes, so that the corresponding pull rods or cables can withstand greater ...

Embodiment 2

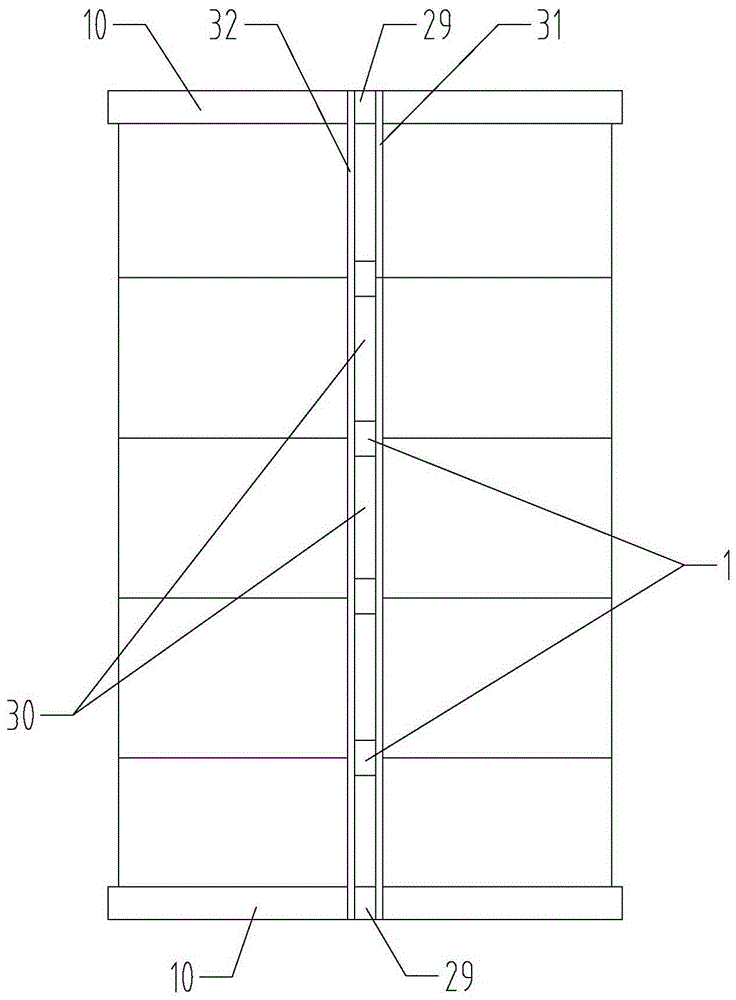

[0031] Example 2, such as Figures 2 to 5 As shown, the portable and stable solar greenhouse includes a thermal insulation wall 10, a light-transmitting film 11, and a plurality of plate-type greenhouse frameworks; The thermal insulation wall 10 includes a wall column 29; the top of the wall column 29 is connected with the top of the center column 1 by a beam 30, and the tops of two adjacent center columns 1 are also connected by a beam 30; The light-transmitting film 11 is sealed and connected to the beam, and the light-transmitting film 11 is sealed and connected to the heat preservation walls 10 on both sides. The greenhouse is quickly formed by a number of quantitatively produced press-plate greenhouse skeletons, with low installation costs and reliable structural strength; at the same time, the overall weight of the greenhouse is reduced, the frame structure load is greatly reduced, the construction technology is simple, and the construction cost is greatly reduced.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com