Glass cleaner with double power sources and control method thereof

A cleaner and dual power supply technology, which is applied in the direction of cleaning machinery, cleaning equipment, emergency power supply arrangements, etc., to achieve the effect of meeting the cleaning process of large areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A glass cleaner with dual power supplies, including a main control part of the washer, a traveling part, a cleaning part, and a power supply part; the traveling part is mainly composed of a rotating bearing driven by a DC motor and a driving wheel connected with the rotating bearing.

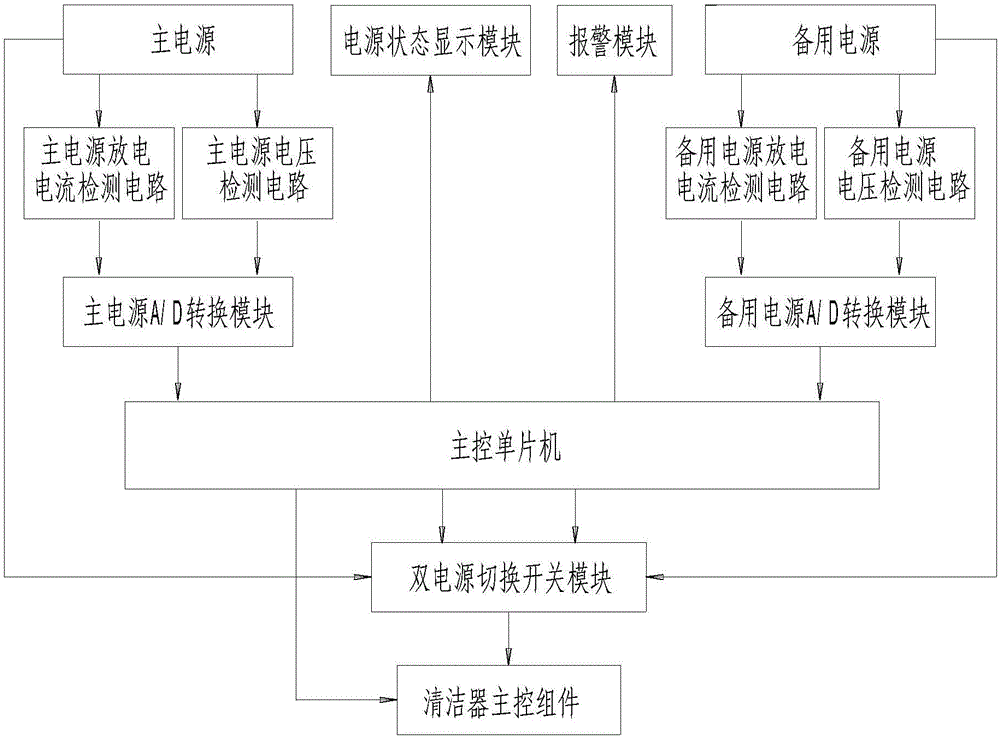

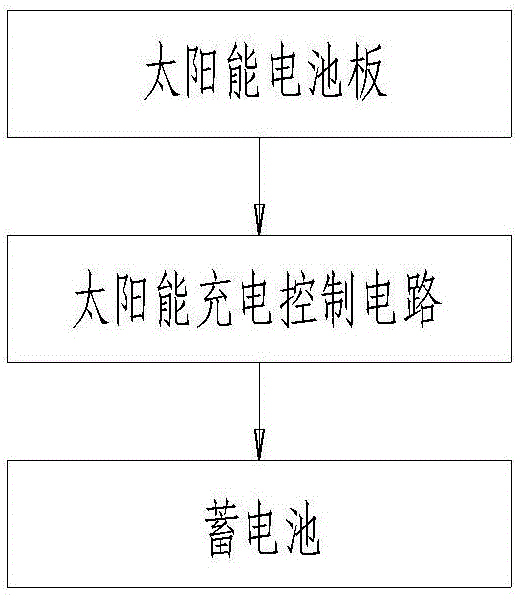

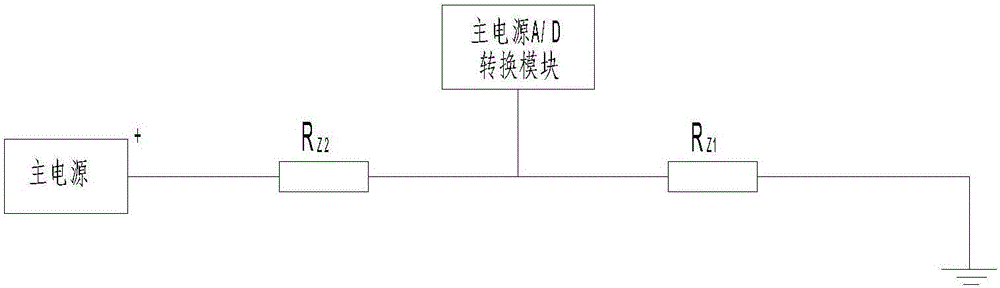

[0036] The power supply unit includes a main power supply, a main power supply discharge current detection circuit, a main power supply voltage detection circuit, a main power supply A / D conversion module, a backup power supply, a backup power supply discharge current detection circuit, a backup power supply voltage detection circuit, and a backup power A / D conversion module. D conversion module, main control single-chip microcomputer, dual power supply switch module, power supply status display module, alarm module; among them,

[0037] The input port of the main control microcontroller is respectively connected to the main power supply discharge current detection circuit and the main pow...

Embodiment 2

[0054] A control method for a glass cleaner with dual power supplies, the method is to respectively detect the discharge current and discharge voltage data of the main power supply through the main power supply discharge current detection circuit and the main power supply voltage detection circuit, and the discharge current and discharge voltage data of the main power supply The data is transmitted to the main control microcontroller through the A / D conversion module of the main power supply; at the same time, the discharge current and voltage data of the backup power are detected respectively through the backup power discharge current detection circuit and the backup power voltage detection circuit. The voltage data is transmitted to the main control MCU through the A / D conversion module of the backup power supply; the main control MCU compares the collected discharge current and voltage values of the main power supply and the backup power supply with the set current and volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com