Patents

Literature

112results about How to "Clean and environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

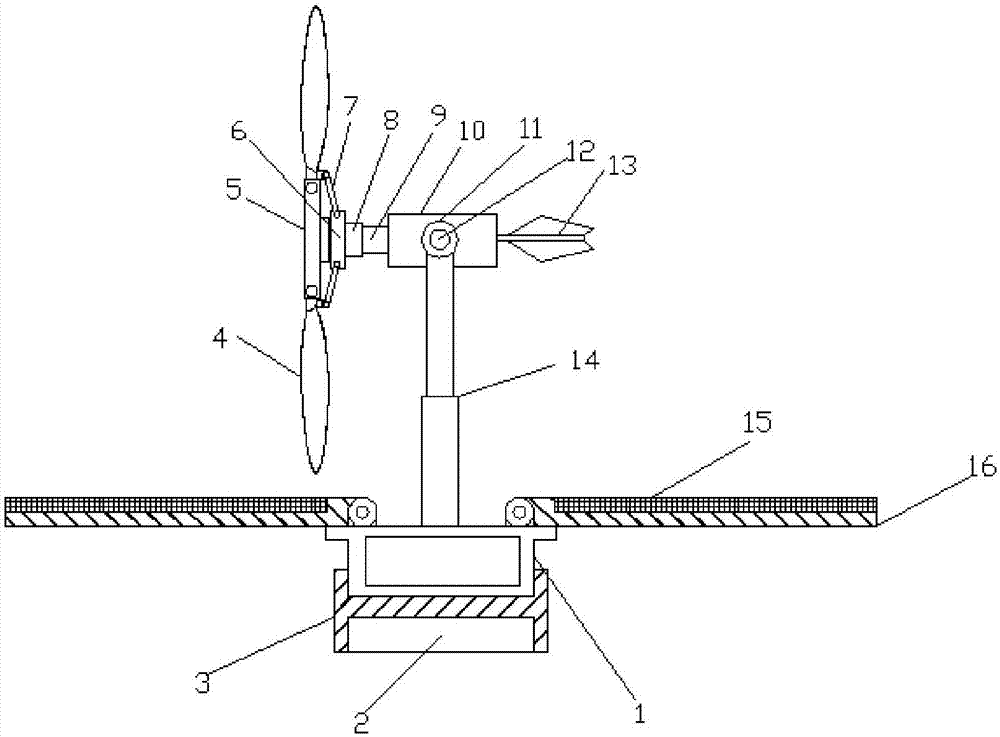

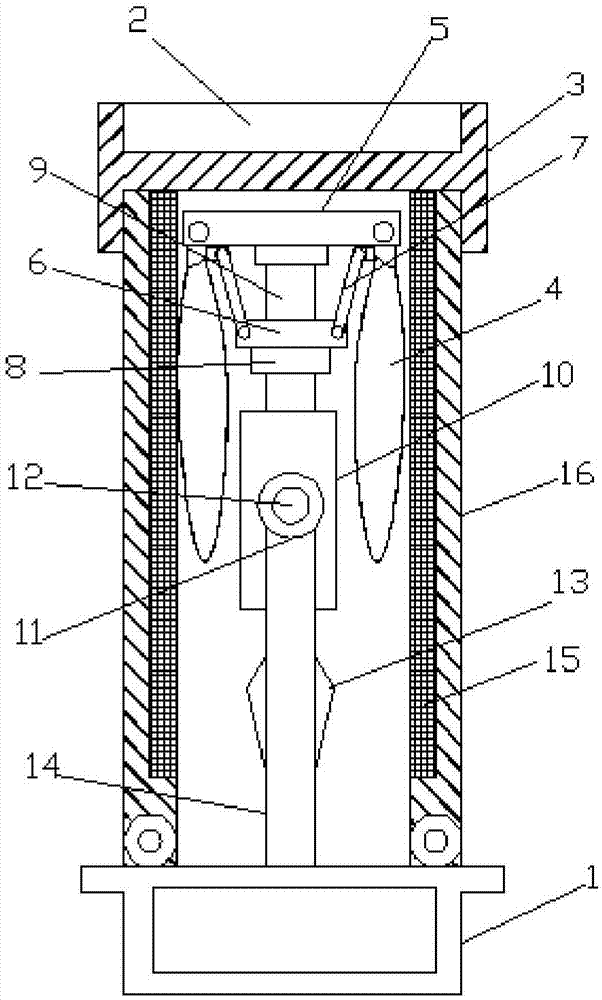

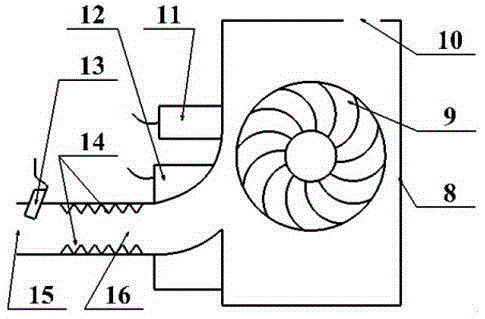

Portable wind and solar power generation device

InactiveCN106979132AReduce volumeEasy to carryPhotovoltaic supportsWind motor with solar radiationNew energyEngineering

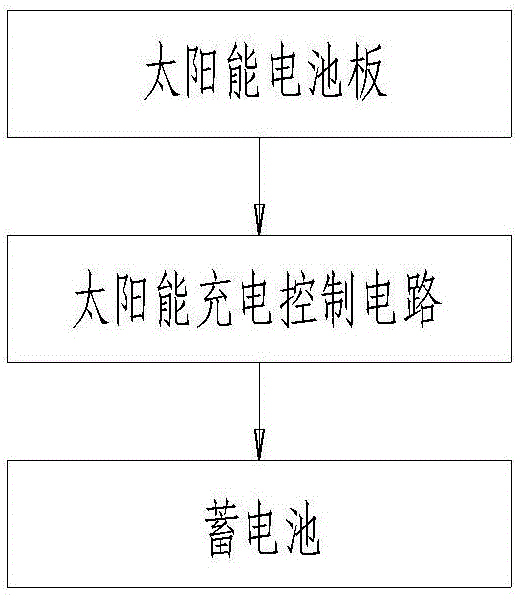

The invention relates to the technical field of power generation devices, in particular to a portable wind and solar power generation device. The portable wind and solar power generation device comprises a solar power generation device body and a wind power generation device body. The wind power generation device body comprises a base; the base is internally provided with a storage battery and vertically provided with a telescopic rod, a rotary shaft is rotationally installed at the upper end of the telescopic rod, a wind power generator shell is rotationally installed on the rotary shaft, a movable nut is installed on the rotary shaft in a threaded mode, and a wind power generator is arranged in the wind power generator shell. The portable wind and solar power generation device is provided with the telescopic and foldable structure, so that the size of the wind and solar power generation device is decreased in a folding state, a user can carry the device conveniently, and improvement is provided for development of new energy resources; and the portable wind and solar power generation device has the characteristics of being clean, environmentally friendly, and flexible, convenient, easy and quick to use.

Owner:成都知联汇科技有限公司

Method for recycling tungsten, vanadium and titanium from SCR waste catalysts

InactiveCN106011503ASequential extractionAchieve mutual separationProcess efficiency improvementTungstateRaffinate

The invention discloses a method for recycling tungsten, vanadium and titanium from SCR waste catalysts. The method comprises the following steps: after the SCR waste catalysts are cleaned, the SCR waste catalysts are smashed and screened, sodium carbonate is doped into the SCR waste catalysts to be evenly stirred, mixed powder is sintered at a high temperature to obtain a sintered material, water is added for leaching out, and a sodium salt mixed solution containing tungsten and vanadium is obtained; under the condition that the pH value of the solution is large than 12, tungsten is selectively extracted, and an ammonium salt solution is used for reverse extraction to obtain an ammonium tungstate solution; under the condition that the pH value of raffinate obtained after tungsten extraction ranges from 10 to 11.5, vanadium is extracted, and a sodium hydroxide solution is used for reverse extraction to obtain a sodium vanadate solution containing a small amount of tungsten; and titanium is left in leaching residues to obtain a rich-titanium material. According to the method, separation of tungsten and vanadium from impurities such as phosphorus, arsenic and silicon is achieved, and primary separation and efficient enrichment of tungsten, vanadium and titanium are achieved.

Owner:无锡市华东电力设备有限公司

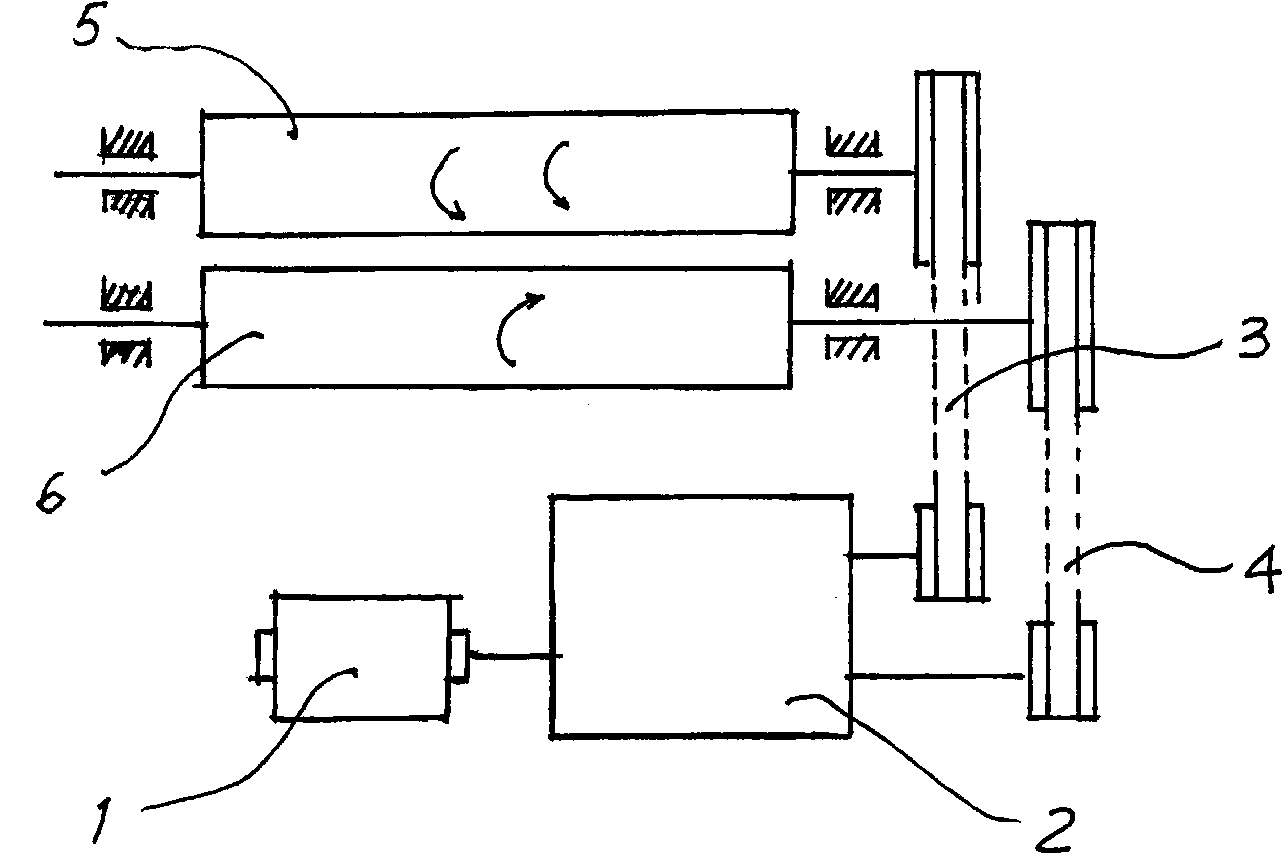

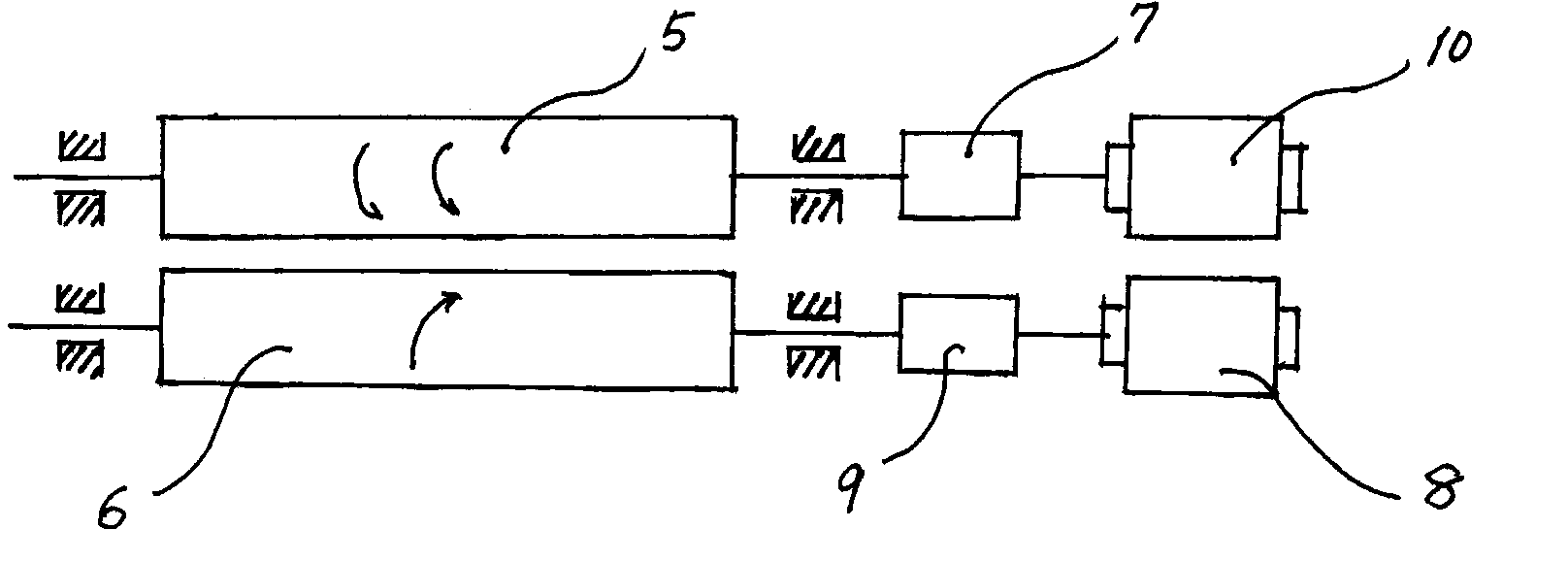

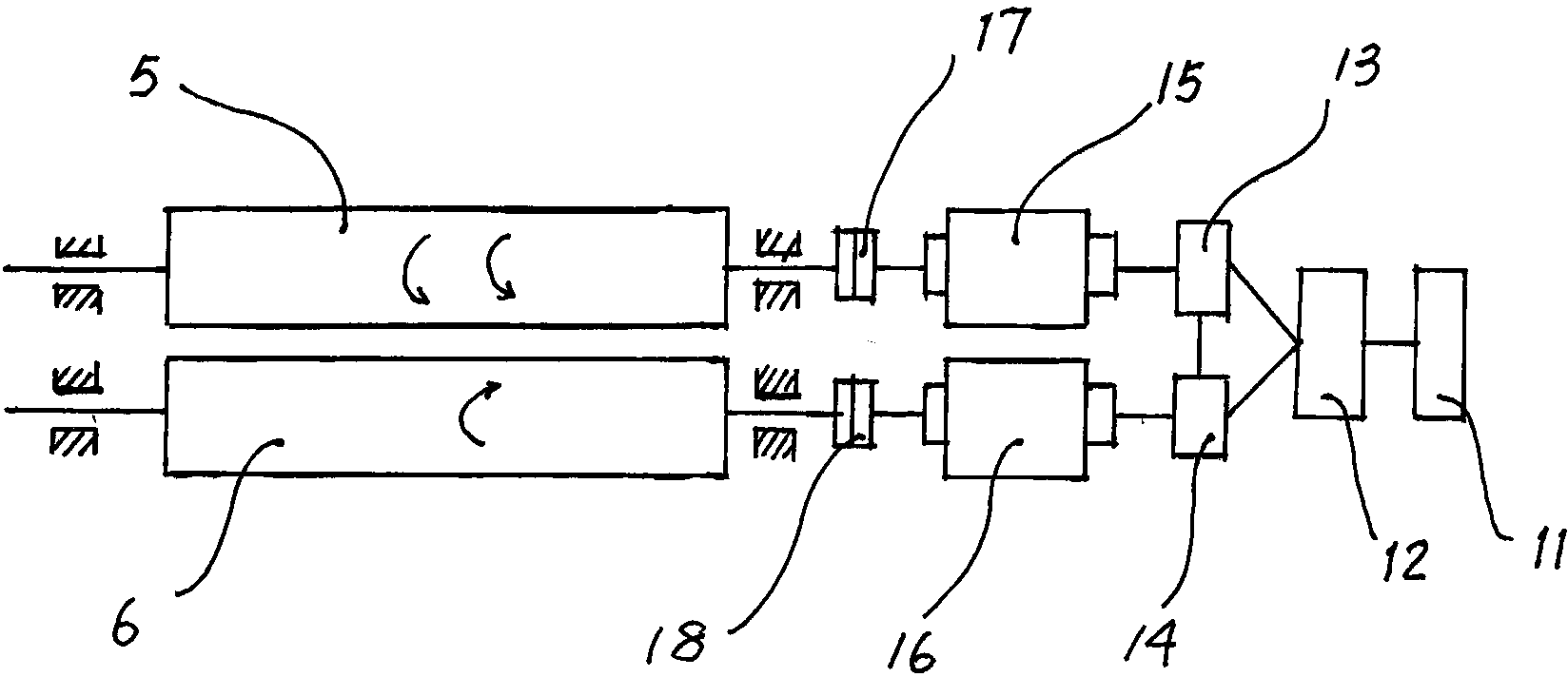

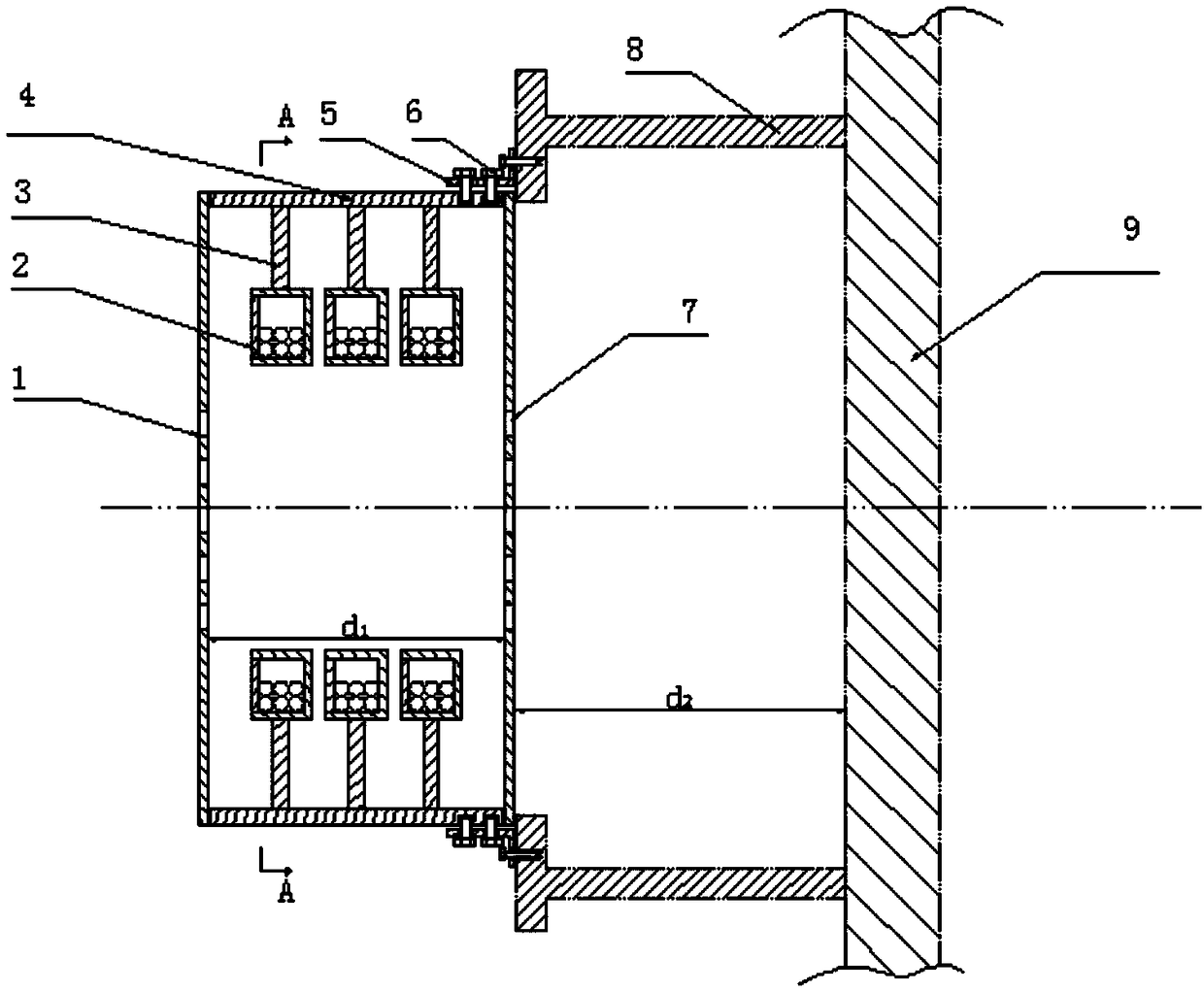

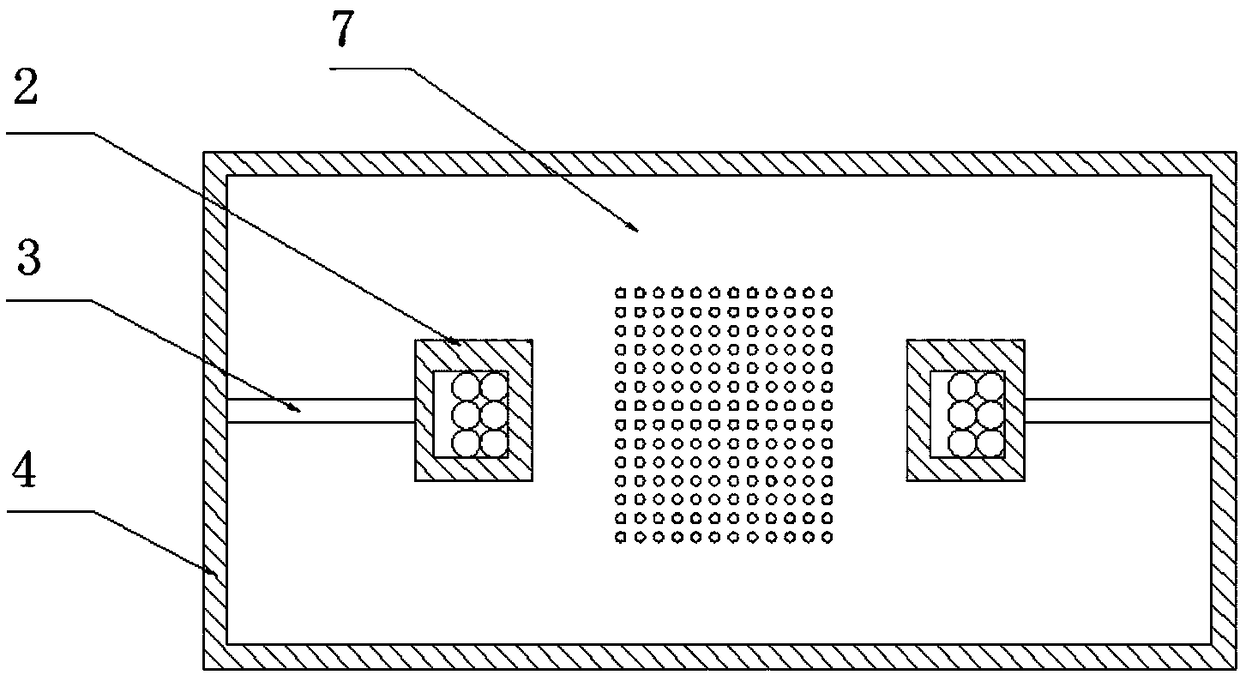

Driving device with double variable frequency motors of rubber roll rice huller

ActiveCN103394386AReduce vibrationReduce noiseGrain huskingGrain polishingFrequency changerLow speed

The invention relates to a grain processing machine, in particular to a driving device with double variable frequency motors of a rubber roll rice huller. The driving device comprises the motors and a coupler, and is characterized by further comprising frequency converters, a touch control screen and a programmable controller, wherein the motors are the variable frequency motors, the touch control screen is connected with the programmable controller, the programmable controller is also connected with the two frequency converters, a guide line is connected between the two frequency converters which are respectively connected with the two variable frequency motors, and main shafts of the two variable frequency motors are connected with a high-speed roll and a low-speed roll through the coupler respectively. The driving device not only is simple in structure, novel, low in noise and convenient to operate, but also maintains the linear speed of the high-speed roll and the linear speed of the low-speed roll and the linear speed difference stable, and enables the rice huller to operate stably and reliably.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

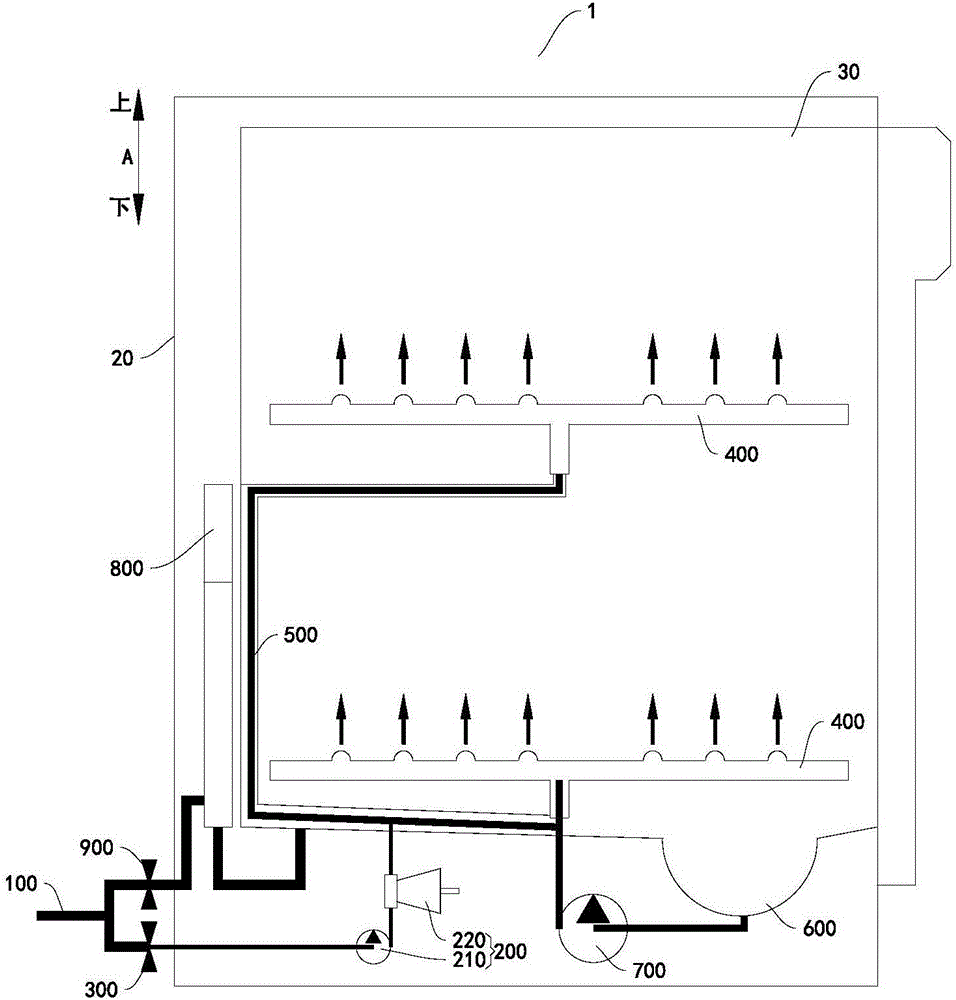

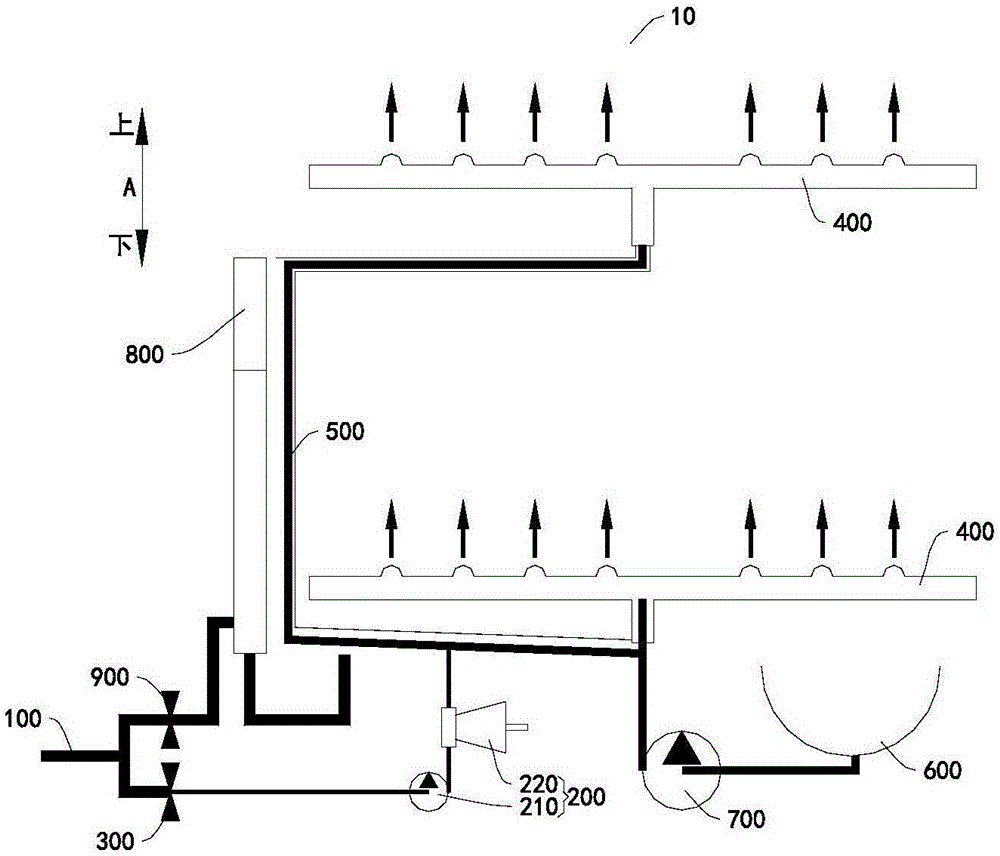

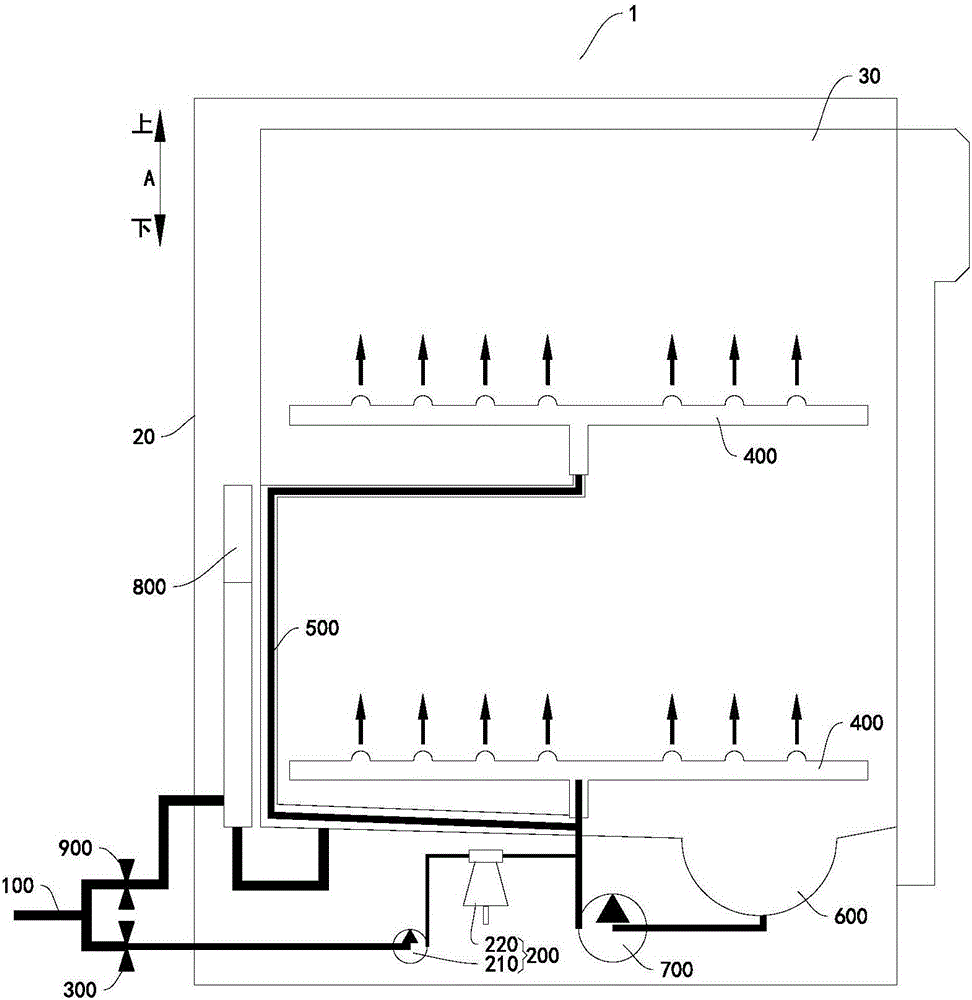

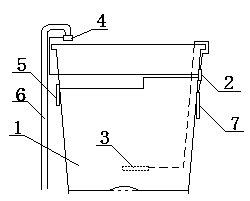

Dishwasher washing system and dishwasher system with same

InactiveCN106821261AImprove washing effectReduce washing costsTableware washing/rinsing machine detailsMicro nanoControl valves

The invention discloses a washing system of a dishwasher and a dishwasher system having the same. The washing system of the dishwasher comprises: a water inlet unit; The washing liquid supplied by the water inlet unit generates micro-nano bubbles in the washing liquid; a first control valve, the first control valve is arranged between the water inlet unit and the micro-nano bubble generating system On the pipeline, wherein the micro-nano bubble generation system is in fluid communication with the inner container of the dishwasher, so as to supply the washing liquid containing micro-nano bubbles generated by the micro-nano bubble generation system to the dishwasher Inside. The washing system of the dishwasher according to the embodiment of the present invention has the advantages of good washing effect, low washing cost, clean and environment-friendly, and the like.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

Aluminum enamel wire production method

ActiveCN101127262AClean and environmentally friendlyEasy to cleanWire articlesInsulated cablesMegasonic cleaningClean water

The utility model relates to a manufacturing method of aluminum enameled wires, in particular to a manufacturing process of aluminum enameled wires via ultrasonic cleaning. In the process, the drawn aluminum wire first undergoes mechanical cleaning, subsequent ultrasonic scrubbing in solution, again mechanical cleaning followed by rinsing with clean water; and once more mechanical cleaning, finally softening and drying. Aluminum enameled wires is produced after painting the dried aluminum wire. The aluminum enameled wire manufacturing method of the utility model and the continuous cleaning / scrubbing in particular has advantages of effective cleaning, wide application range, cleanness and environmental protection, not easy peel-off of the enameled wire.

Owner:ROSHOW TECH

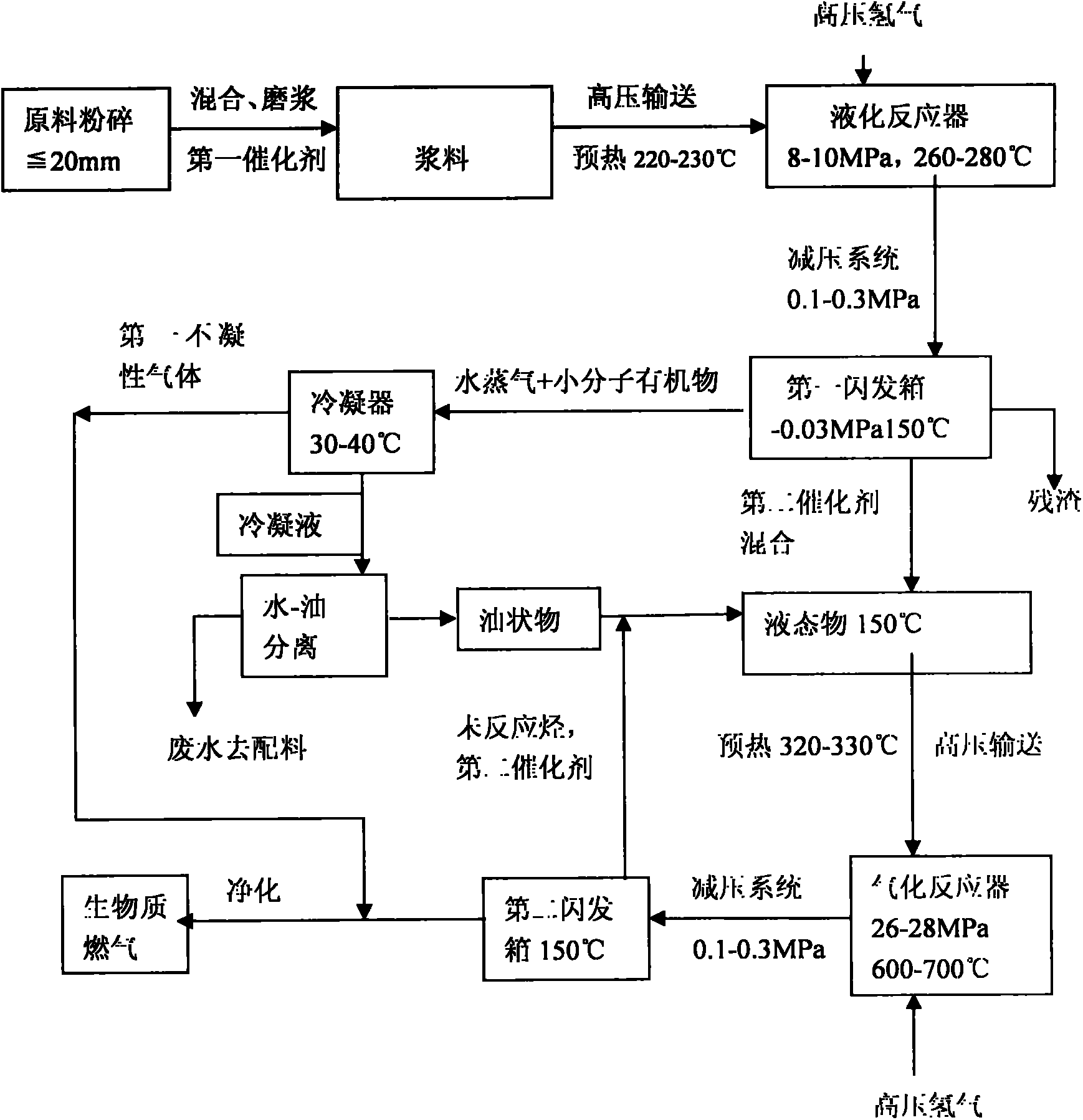

Method for preparing biomass gas from plant branches and trunks

InactiveCN102382683AHigh yieldReduce liquefaction processing timeHydrogenLiquid hydrocarbon mixture productionBiomassChemistry

The invention discloses a method for preparing biomass gas by using plant branch and trunk type biomasses as raw materials, which comprises the following steps of: 1) carrying out hydro-thermal liquefaction treatment on plant branches and trunks, water and first catalysts for preparing first non-condensable gas and first liquid mixtures; 2) carrying out cracking and gasification treatment on the first liquid mixtures and second catalysts to obtain second non-condensable gas; and 3) obtaining the biomass gas through the purification and the impurity removal of the first non-condensable gas and the second non-condensable gas. The method is used for preparing the clean and environmental biomass gas with high fuel thermal value by using agricultural / forest wastes as the raw materials, the product yield is high, and the biomass gas prepared by the invention is used as gas, has the same equivalent efficiency as coal gas and natural gas and belongs to the development direction of biological energy source industry.

Owner:INNER MONGOLIA JINDI BIOMASS

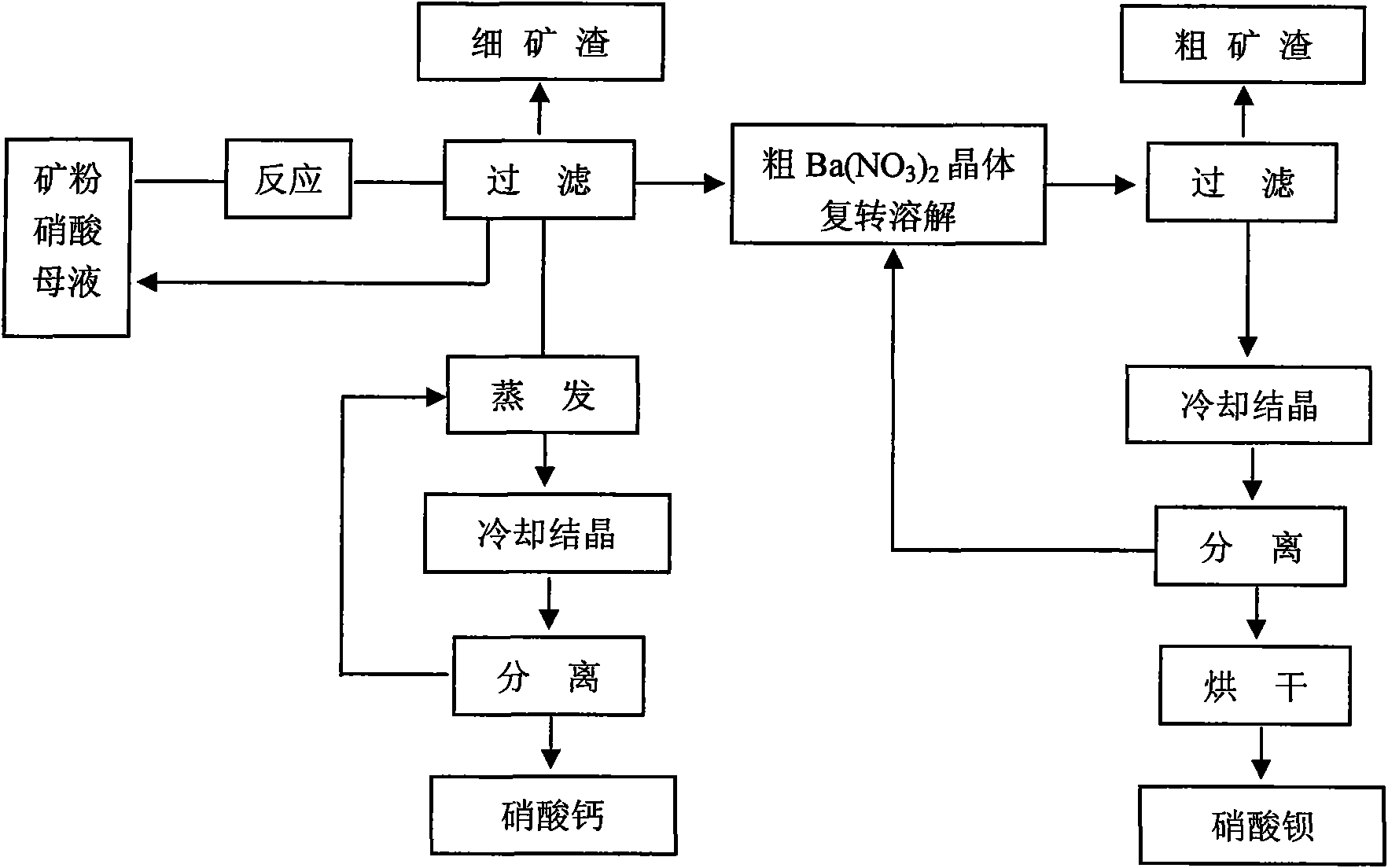

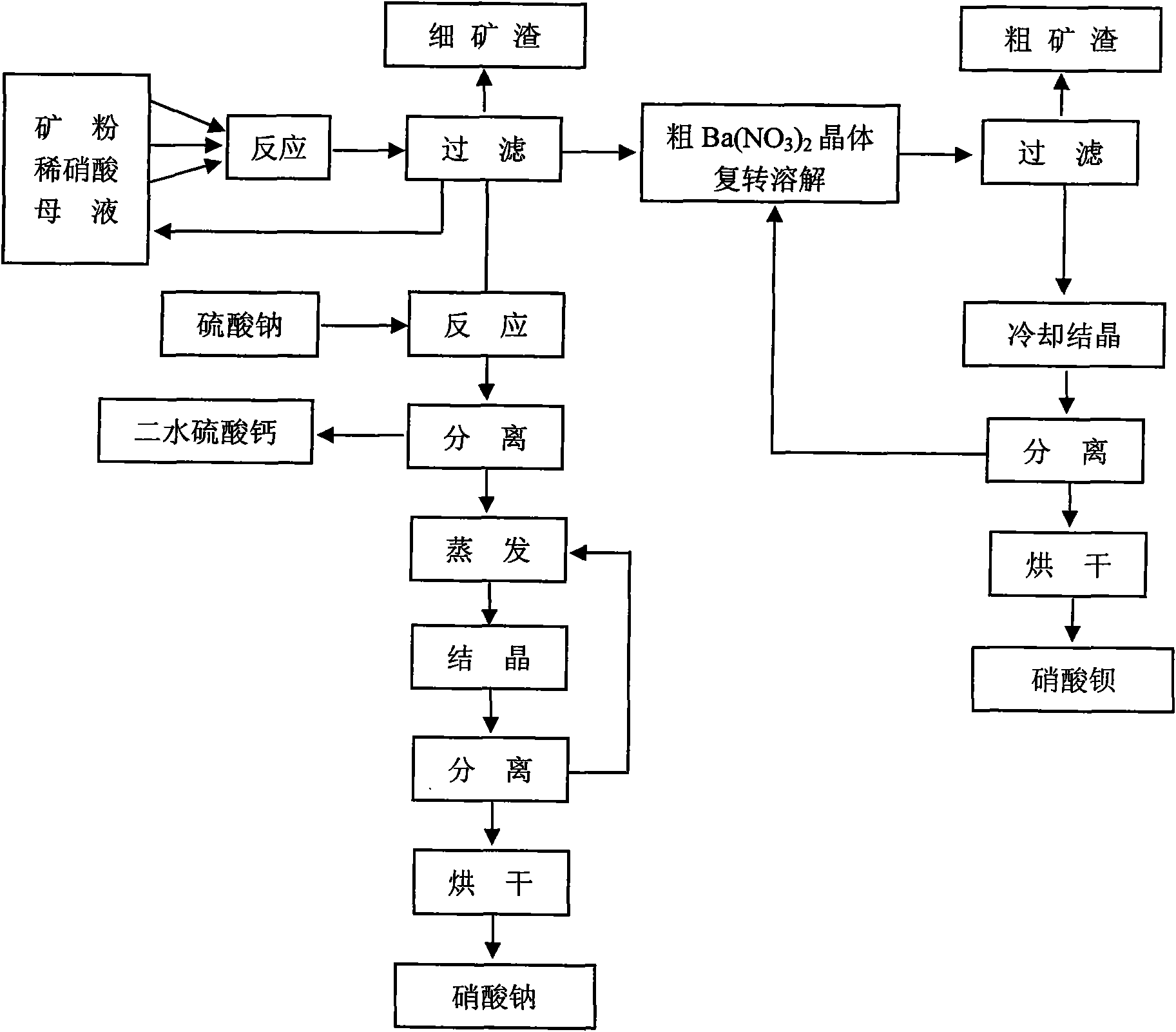

Method for preparing barium nitrate, calcium nitrate, calcium sulfate and sodium nitrate by utilizing middle and low grade barium carbonate ore

InactiveCN101559967AAchieve comprehensive utilizationLow costCalcium/strontium/barium sulfatesAlkali metal nitrate preparationBarium nitrateSulfate

The invention discloses a method for preparing barium nitrate, calcium nitrate, calcium sulfate and sodium nitrate by utilizing a middle and low grade barium carbonate ore, which is characterized in that the middle and low grade ore of BaCo3 with the content of between 30 and 72 weight percent and CaCO3 with the content of between 15 and 45 weight percent and nitric acid react to prepare the barium nitrate and the calcium nitrate; or the middle and low grade ore and the nitric acid react to prepare the barium nitrate, the double decomposition reaction of a residual mother solution (a calcium nitrate solution) and sodium sulfate are performed to prepare the calcium sulfate and the sodium nitrate, and a small amount of acid undissolved substance is used for cement additive. The method achieves the comprehensive utilization of raw materials, has no discharge of three wastes, and has the advantages of cleanliness, environmental protection, high product quality, and low cost.

Owner:SICHUAN UNIV

Soil conditioner and preparation method and application thereof

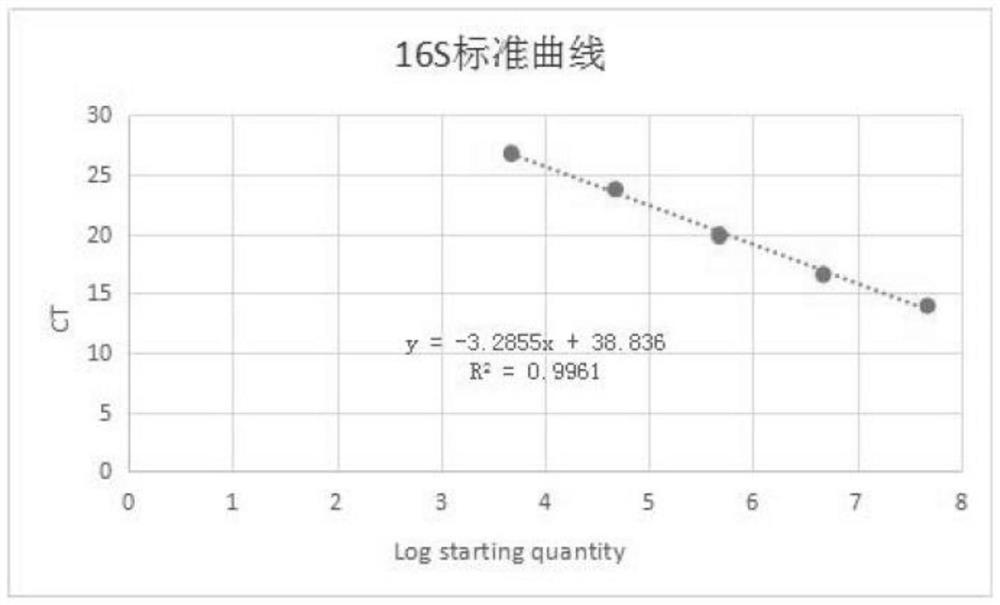

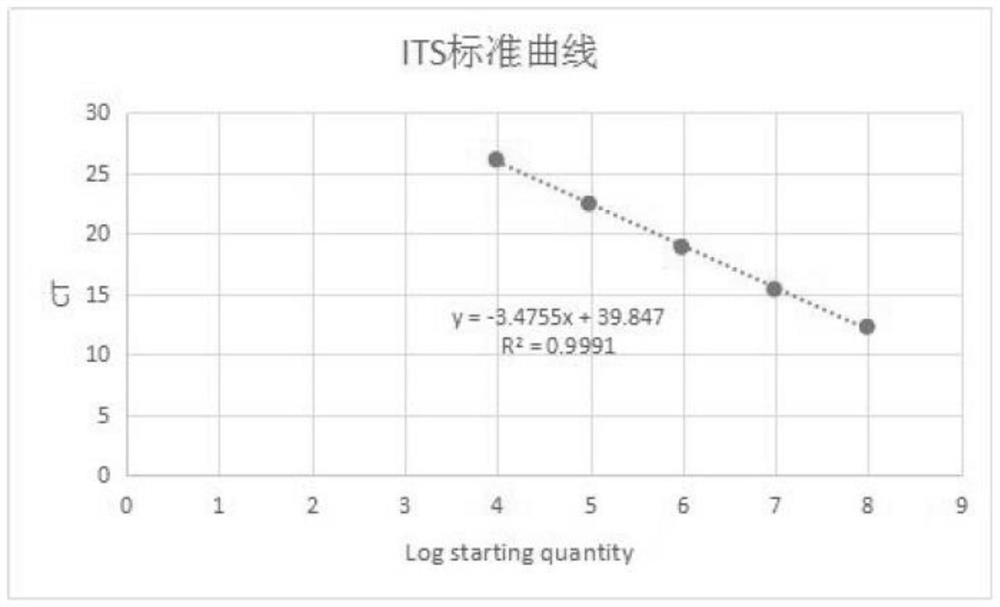

ActiveCN111778032APromote growthIncrease productionAgriculture tools and machinesOrganic fertilisersContinuous croppingSoil science

The invention discloses a soil conditioner as well as preparation and application thereof. The soil conditioner is prepared from biomass charcoal, an oxidizing agent, an iron-containing inorganic matter and a binder in proportion through the steps of burdening, oxidizing agent particle preparation, biomass charcoal-iron-containing inorganic matter wrapping, drying and the like. The soil conditioner can effectively remove allelochemicals in continuous cropping soil, improve the physical and chemical properties of the soil, regulate and control the microbial structure of the soil, reduce soil-borne diseases, improve the yield and quality of vegetable crops such as tomatoes and cucumbers, and provide effective technical support for sustainable development of green agriculture.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

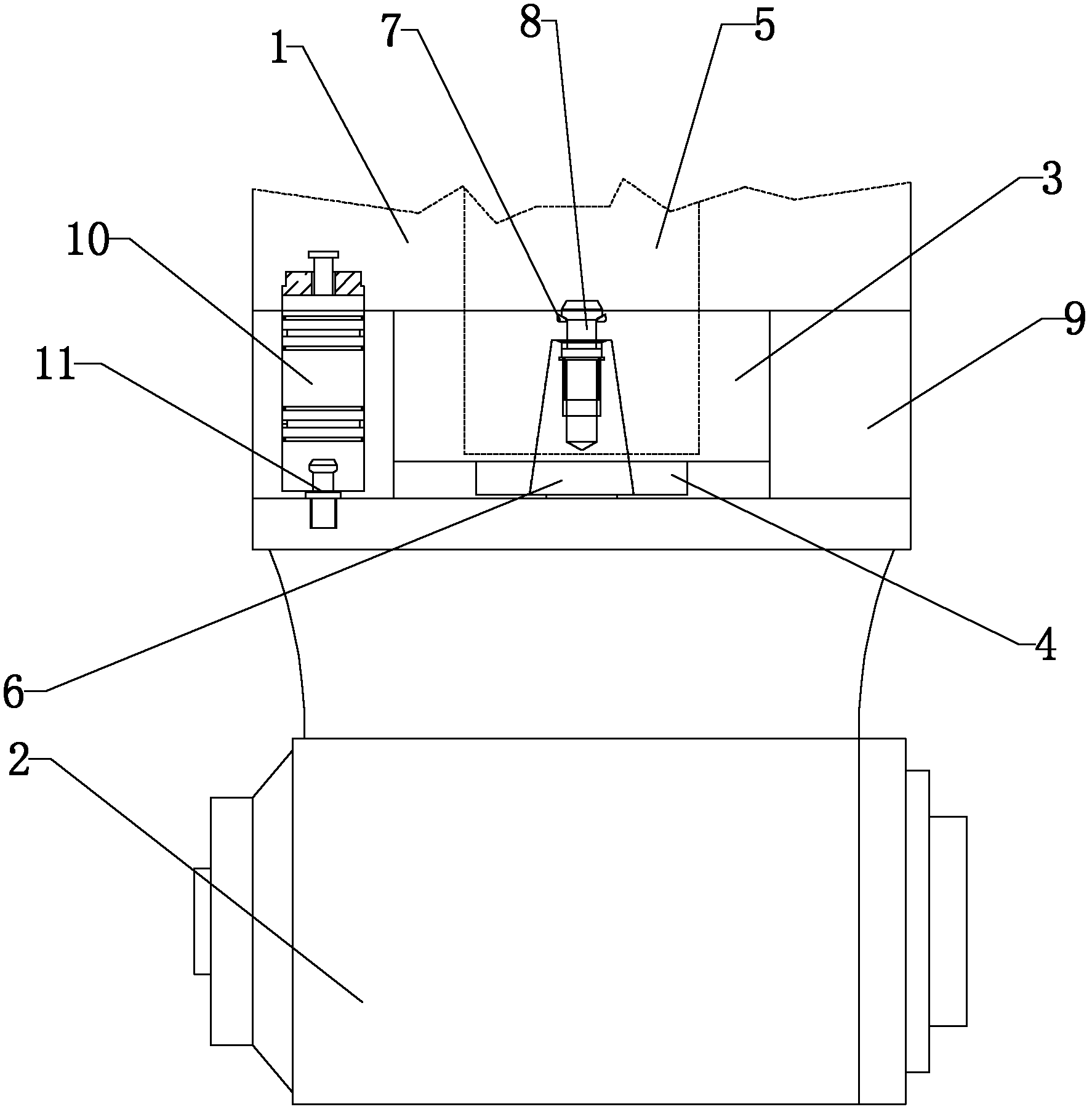

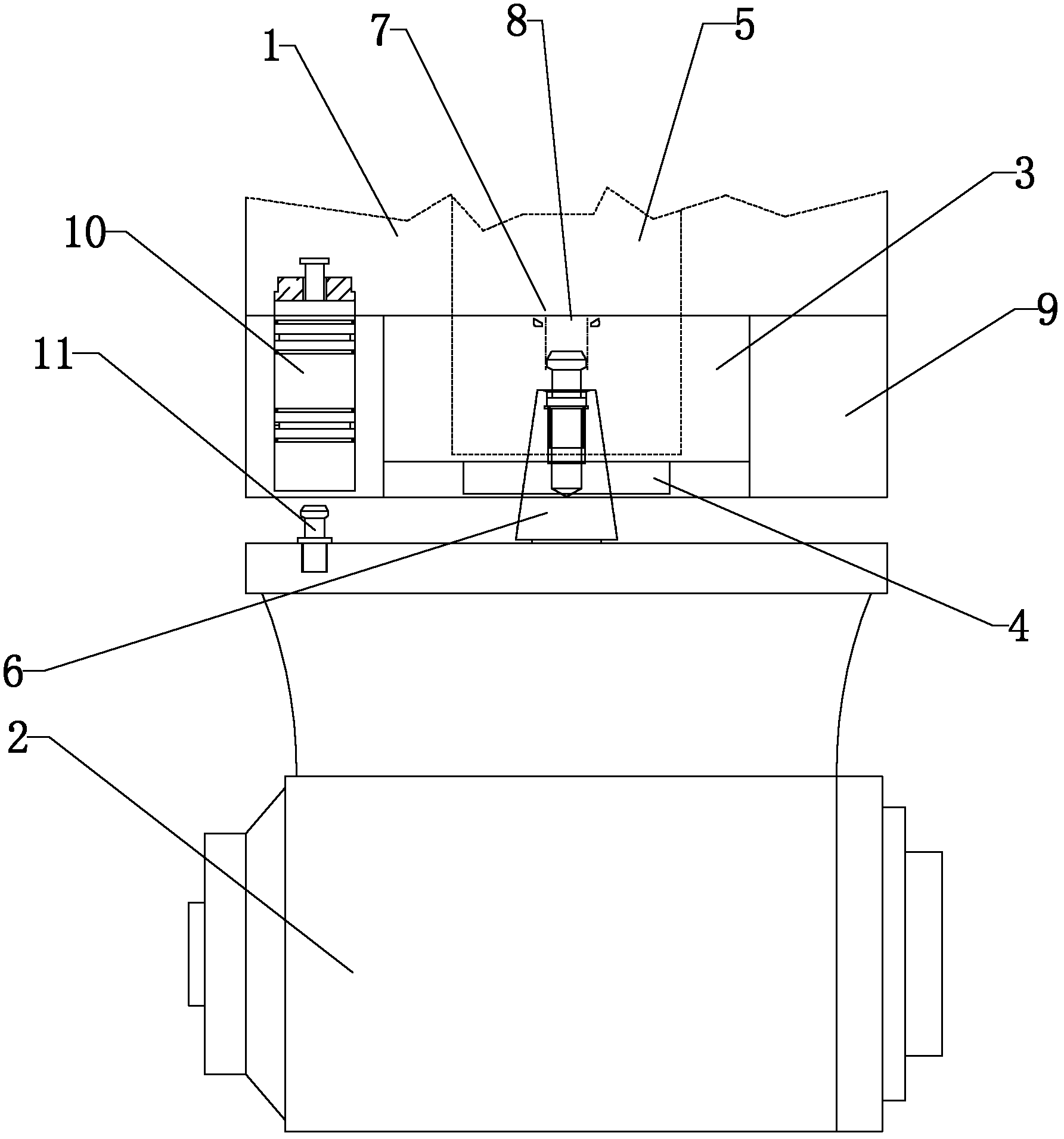

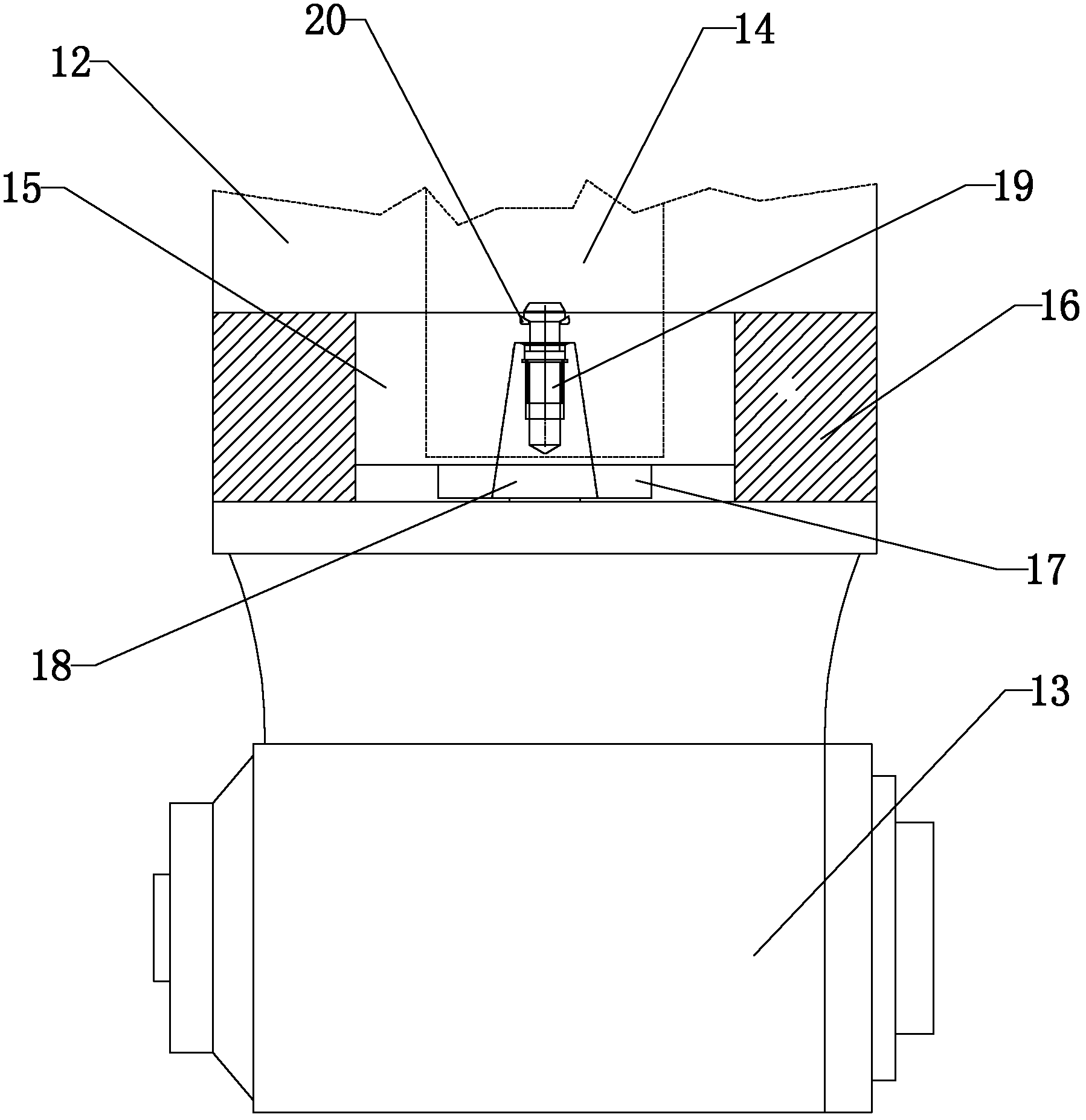

Electromagnetic clamping device for mechanical milling head

InactiveCN102284738AClean and environmentally friendlyPlay the role of green and low carbonMilling equipment detailsPositioning apparatusMechanical millingFuel tank

The invention relates to an electromagnetic clamping device for a mechanical milling head, comprising a ram and a mechanical milling head, a protrusion is provided at the bottom of the ram, a main shaft is provided inside the ram and the protrusion, and one end of the main shaft is connected and clamped. system, the other end of the main shaft is provided with a tapered handle, and the top of the tapered handle is provided with pulling claws. The mechanical milling head is provided under the protrusion, and the top of the mechanical milling head is provided with a pull stud integrated with it. The pull stud passes through the The pulling claw is fixed, and an electromagnet located outside the protrusion is arranged under the ram. The beneficial effects of the present invention are as follows: replace polluted hydraulic oil with non-polluting electric energy, and play the role of cleaning, environmental protection, green and low-carbon; the traditional vertical machining center can realize the vertical and horizontal conversion of the machining direction, which greatly improves the Improve the processing range and processing efficiency of the machine tool, realize multi-process processing in one clamping, and improve the processing accuracy of the product; compared with the high price of the oil cylinder system, the cost of the electromagnetic system is more economical, and it is more suitable for use on economical machining centers.

Owner:北京伊贝格机械有限公司

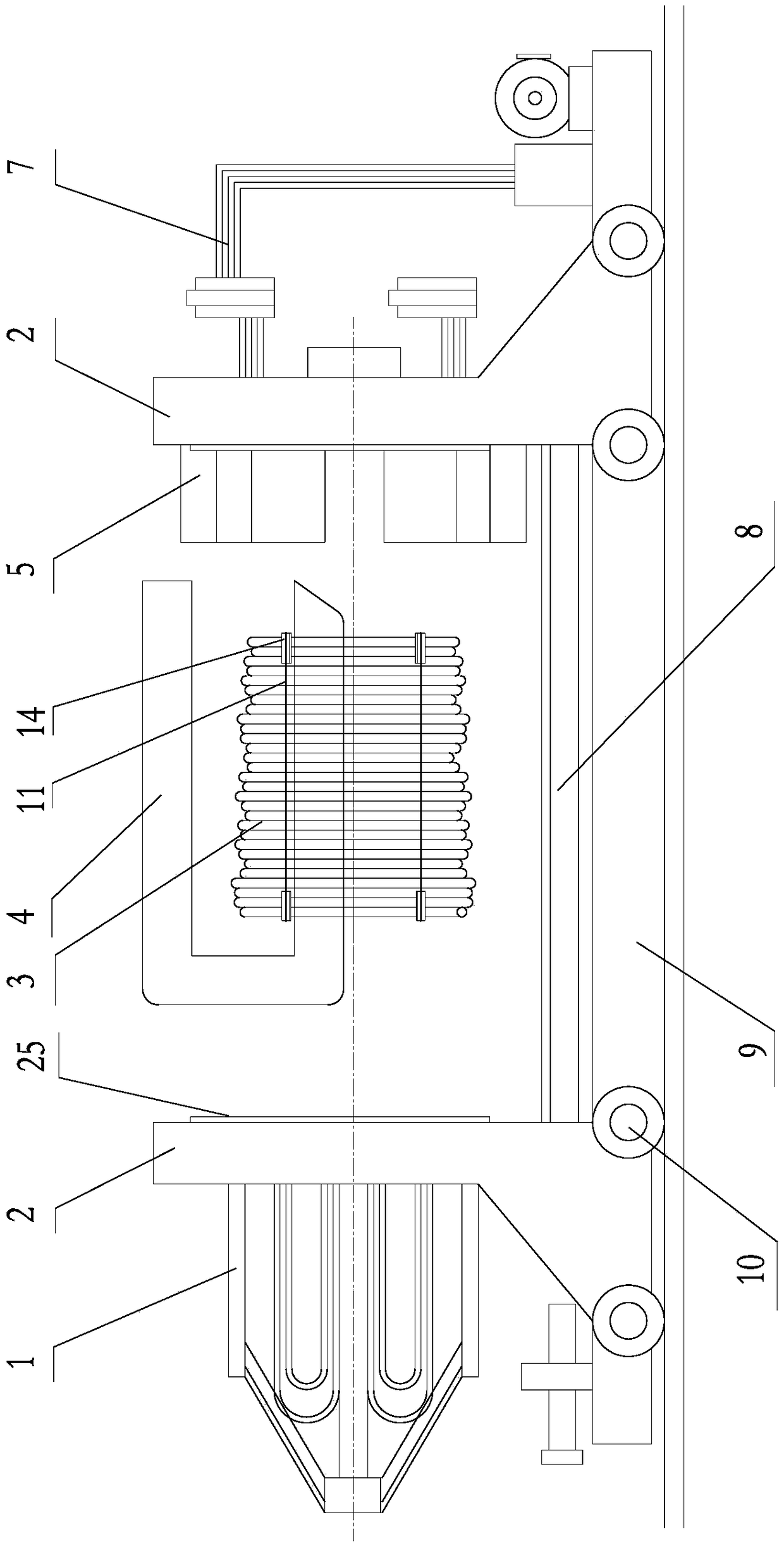

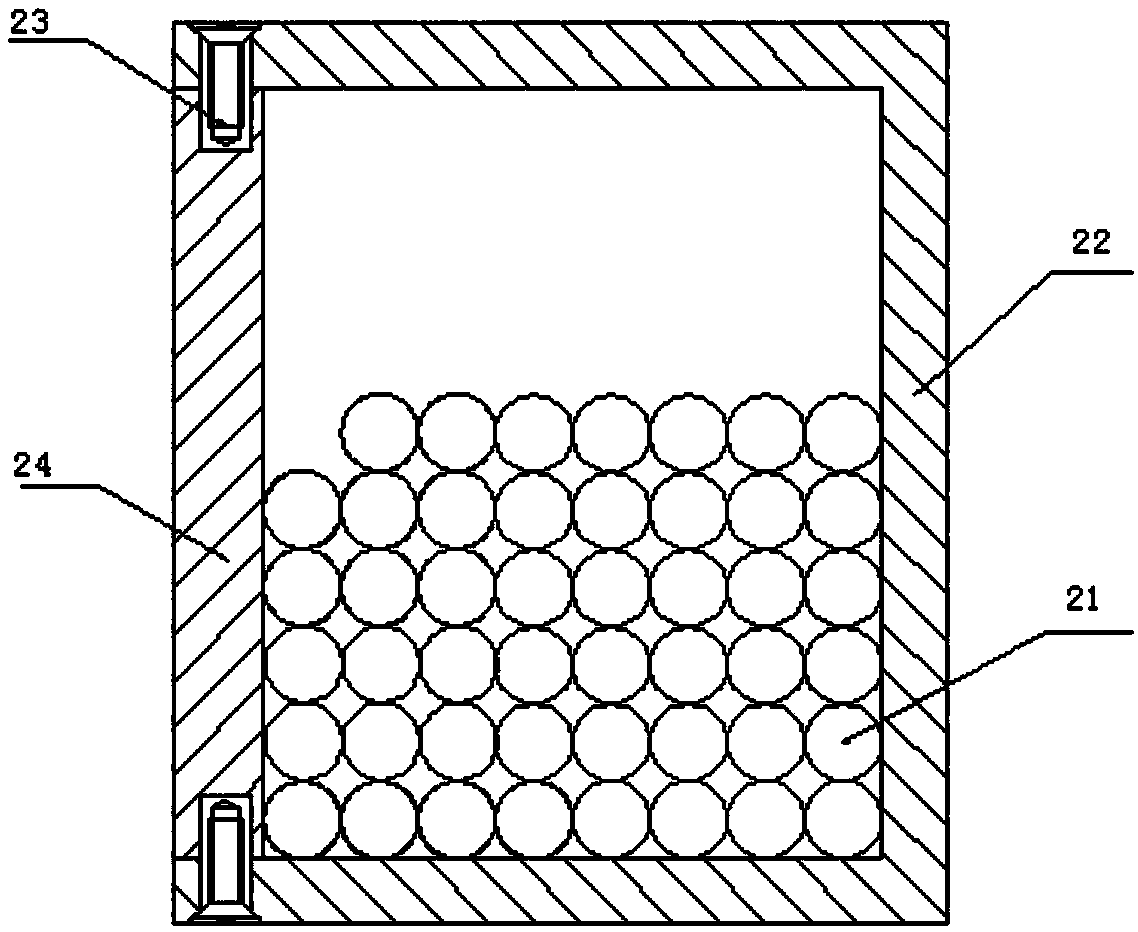

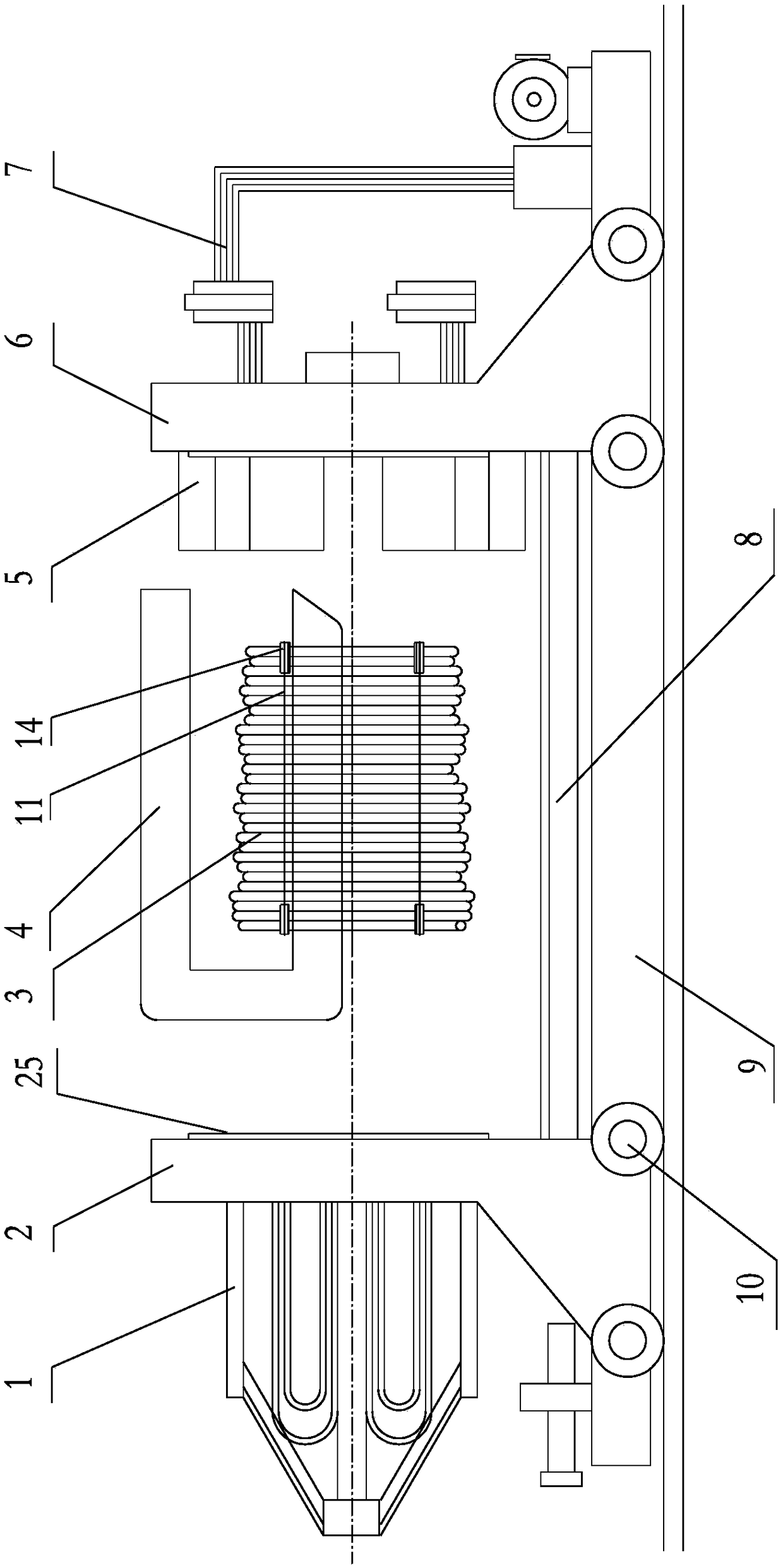

Gasket containing mechanism of high-speed wire rod packaging machine

InactiveCN109305424AClean and environmentally friendlyRealize environmental protectionBundling machine detailsWire rodChemical synthesis

The invention relates to a machine and tool improved mechanism used in procedures of steel rod machining, wire rod forming and packaging in the field of steel metallurgy. According to a gasket containing mechanism of a high-speed wire rod packaging machine, continuous pushing mechanisms (15) for gaskets (14) are arranged at the four opposite corner positions of pressing plates (2) correspondingly;the gaskets (14) are metal sheets or chemical synthesis sheets; the multiple gaskets (14) are arranged and are pushed by the continuous pushing mechanisms (15) one by one to penetrate through a channel avoided through an anti-scratching disc (25) to the positions of wire grooves (18) of the pressing plates (2), and the binding and winding direction of the gaskets (14) is consistent to the direction of the wire grooves (18). The continuous pushing mechanisms (15) are arranged on pressing faces of the pressing plates (2) or the pressing faces and the side faces of the pressing plates (2) and lengthened plates with outward pressing faces. According to the gasket containing mechanism, a pure machine operation improved structure different from an existing gasket containing manner is provided for the first time, the labor intensity and danger of manual gasket containing are reduced, the operation speed, efficiency, quality and effect are greatly improved, and urgent popularization and application value is achieved.

Owner:SHANGHAI WINLONG ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

A composite structural member for reducing noise and vibration in a ship cabin

ActiveCN109018193AReduce vibrationEnhanced Damping ControlHull panellingsMicro perforated plateWorking environment

The invention discloses a composite structural member for reducing noise and vibration in a ship cabin., The member comprises a outer layer micro-perforated plate, a framework and an inner layer micro-perforated plate, all of which are connected through connecting parts and enclosing walls for a chamber. The outer layer micro-perforated plate and the inner layer micro-perforated plate are fixedlyconnected and combined into a double-layer micro-perforated cavity through a frame, and a plurality of rows of multi-layer particle dampers are fixedly connected on two side walls corresponding to the frame in the cavity through elastic connecting rods. The outer layer micro-perforated plate and the inner layer micro-perforated plate are fixedly connected to each other through a frame. The invention can optimize the sound absorption coefficient of the micro-perforated plate without changing the cabin structure, broaden the sound absorption frequency band, improve the sound absorption effect,reduce the vibration of the cabin structure, and create a good cabin working environment. Moreover, the invention has the advantages of compact structure and convenient installation. It has a good prospect of engineering application.

Owner:JIANGSU UNIV OF SCI & TECH

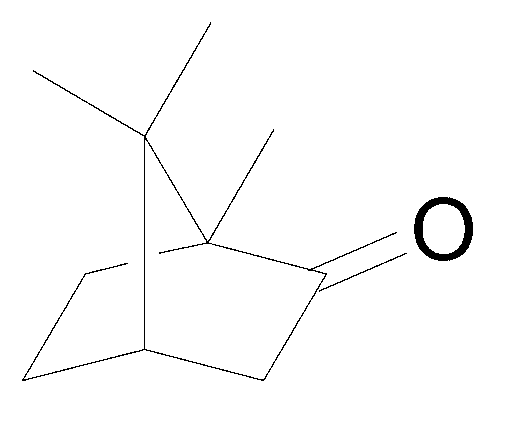

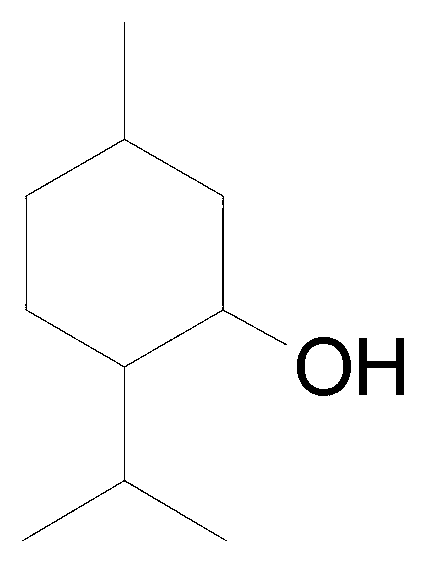

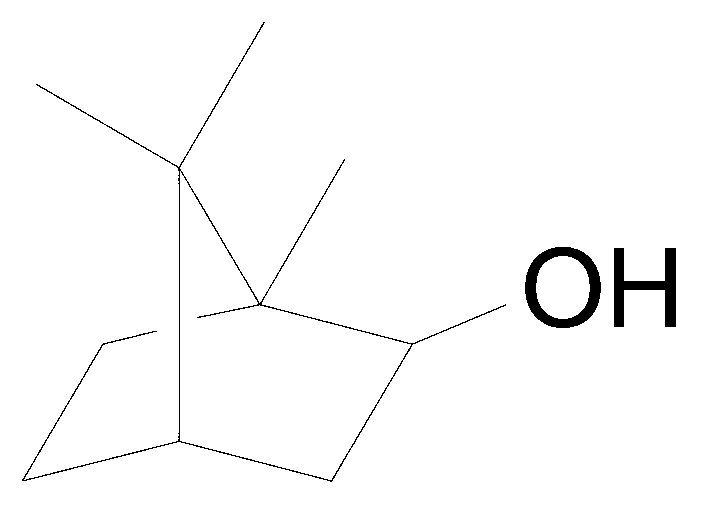

Formula for fuel saving ingot

ActiveCN103074127AThe composition is stableComposition material safetyLiquid carbonaceous fuelsFuel additivesStearic acidStearate

The invention discloses a formula for a fuel saving ingot. The formula comprises the following components: camphor, palmitic acid, stearic acid, centanol, menthol, borneol, phenyl stearate, cetyl palmitate and ferrocene, wherein the content of camphor is 30-90wt%, the content of palmitic acid is 4-10wt%, and the content of stearic acid is 4-10wt%. The components of the formula are stable, safe, small in toxicity and low in cost; no secondary pollution is generated; fuel is saved by above 15%; and an octane value can be increased.

Owner:APEX GRAPHENE GRP INC

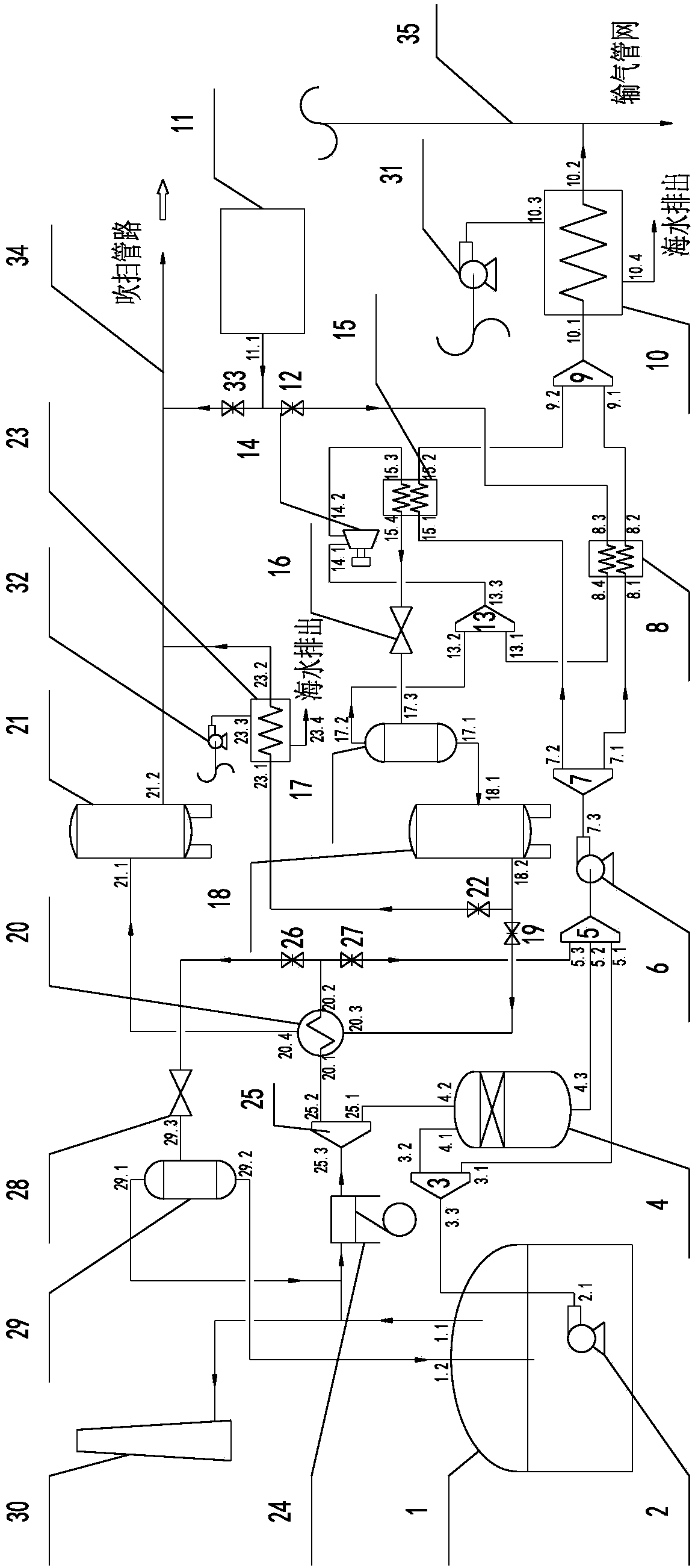

BOG recycling and nitrogen liquefying system and technological method

ActiveCN107560321AImprove utilization efficiencySolve recycling difficultiesSolidificationLiquefactionEnvironmental engineeringNitrogen gas

The invention discloses a BOG recycling and nitrogen liquefying system and technological method. According to the BOG recycling and nitrogen liquefying system, two-grade cooling is conducted on nitrogen prepared by a PSA nitrogen-making device through LNG cold energy, so that the nitrogen is liquefied and stored; in the BOG liquefying system, BOG is pressurized through a compressor and then conducts heat exchange with the liquid nitrogen, so that the BOG is liquefied, the liquid nitrogen absorbs heat and is gasified and stored in a nitrogen storage tank, and the nitrogen can be used for station blowing; the liquefied BOG enters a high-pressure pump to be output, or the liquefied BOG is decompressed through throttling and then enters a separator, the liquid-phase BOG is fed into the bottomof a LNG storage tank to be stored, and the gas-phase BOG enters a BOG compression cycle. By the adoption of the BOG recycling and nitrogen liquefying technological method, the problem that BOG recycling is difficult when the output amount of an LNG receiving station is low is solved, the demand for the low-temperature blowing technology of the station is met, the energy utilization rate is improved since LNG cold energy is utilized, and the equipment investment is reduced since existing PSA nitrogen making equipment of the LNG station is utilized.

Owner:YANGTZE UNIVERSITY

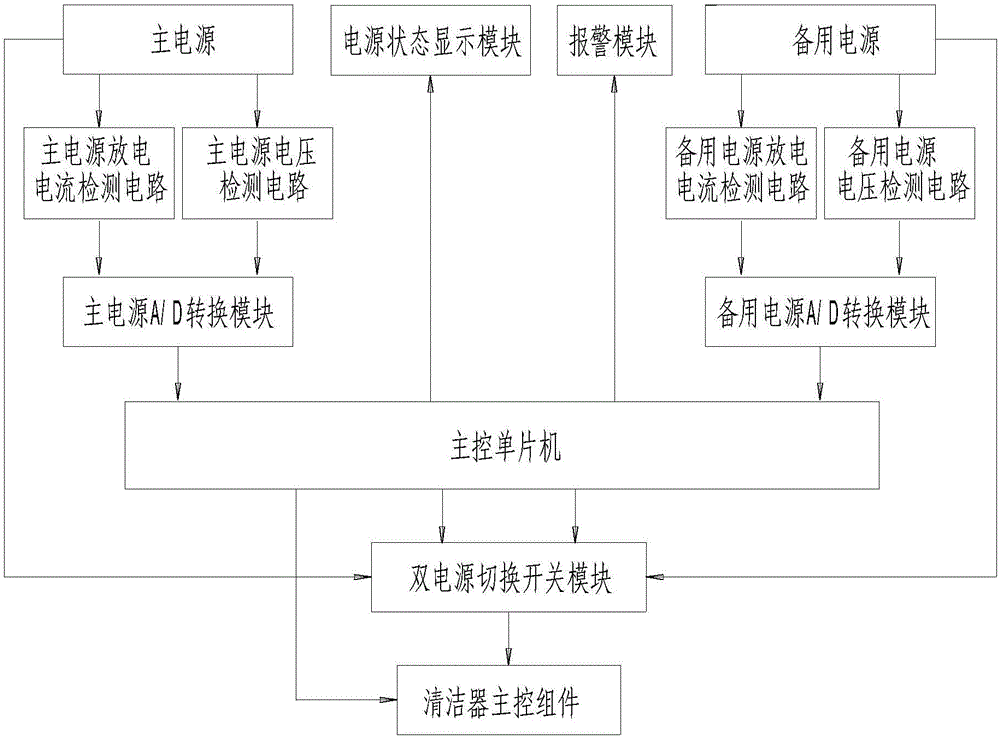

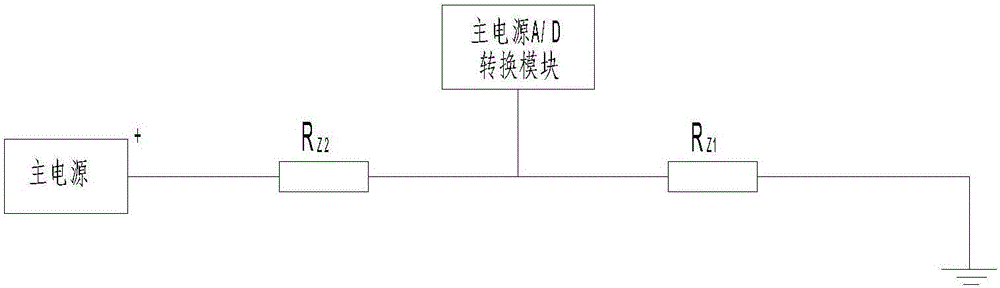

Glass cleaner with double power sources and control method thereof

ActiveCN106618405ARealize automatic switchingMeet the needs of large area cleaning processesCarpet cleanersPower network operation systems integrationPower flowStandby power

The invention relates to a glass cleaner and a control method thereof, in particular to a glass cleaner with double power sources and a control method thereof. The cleaner comprises a cleaner main control part, a walking part, a cleaning part and a power supply part; the power supply part comprises a main power source, a main-power-source discharging current detection circuit, a main-power-source voltage detection circuit, an emergency power source, an emergency-power-source discharging current detection circuit, an emergency-power-source voltage detection circuit, a main control single-chip microcomputer, a double-power-source selector switch module and the like. The control method includes the steps that current data and voltage data of the main power source are detected through the main-power-source discharging current detection circuit and the main-power-source voltage detection circuit respectively, the data is compared with a set current threshold value and a set voltage threshold value through the main control single-chip microcomputer, and whether the emergency power source is switched on through the double-power-source selector switch module or not is determined. By means of the glass cleaner and the control method, automatic switching of the double power sources can be achieved, continuous power supplying of the glass cleaner is guaranteed, the requirements of the large-area cleaning process of the glass cleaner can be met, and the glass cleaner has the advantages of being environmentally friendly in cleaning, high in intelligent degree and the like, and is easy to apply and popularize.

Owner:柳州极讯云科技有限公司

Ficoll synthesis process method

ActiveCN102690364AClean and environmentally friendlyContinuous productionEnvironmental resistanceFicoll

The invention discloses a ficoll synthesis process method which comprises the following steps: (1) filling alkalic anion exchange resin into a fixed bed reactor; (2) adding a mixture prepared by sucrose, a cross-linking agent, distilled water, an oil phase and a dispersant into the fixed bed reactor, so that the mixture can conduct polyreaction on the alkalic anion exchange resin; (3) reacting for 4 to 5 hours at 22 to 28 DEG C, increasing the temperature to be 50 to 95 DEG C, and reacting for 2 to 5 hours under water bath again; (4) repeatedly washing by absolute ethyl alcohol and adsorbing a reaction product on the alkalic anion exchange resin, and eluting to obtain ficoll. The synthesis process has the characteristics of simple and convenient preparation process, mild reaction condition, less side reaction, repeated use of a catalyst, no problem of separation from the product, continuous production, cleanness, environmental protection and the like, and moreover, ficoll with good water-solubility and high reaction activity can be obtained. Therefore, the synthesis process has a wide application prospect.

Owner:ADANA FOOD TECH LIUZHOU

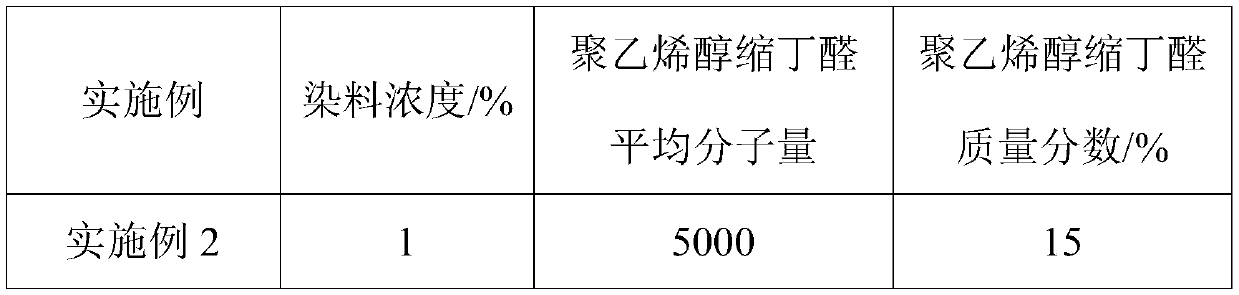

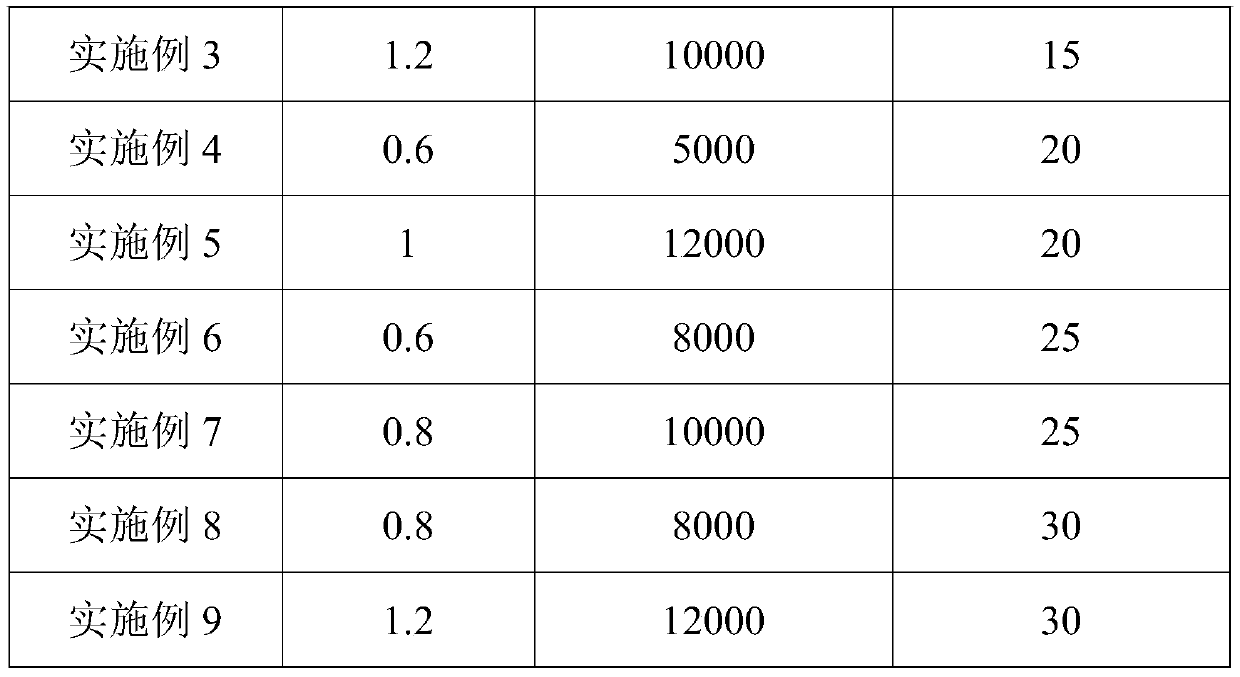

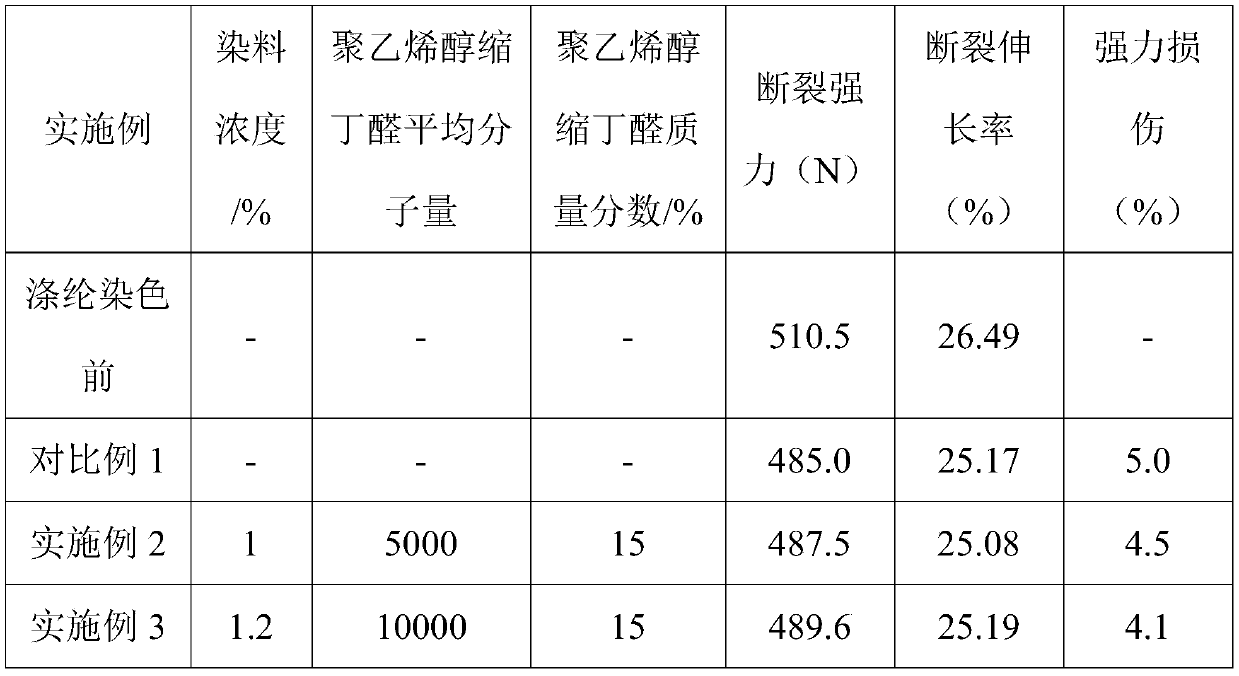

Method for quickly dyeing polyester textiles

ActiveCN110219182AHigh elongation at breakStrong damageHeating/cooling textile fabricsDyeing processWater bathsDispersion stability

The invention relates to a method for quickly dyeing polyester textiles, and belongs to the technical field of textile printing and dyeing. The method for quickly dyeing the polyester textiles includes the following steps: step 1, dissolving disperse dye macromolecular polyvinyl butyral, penetrants, dispersants and expansion agents in an alcohol organic solvent to obtain mixed dyeing size; step 2,padding the polyester textiles in the mixed dyeing size; step 3, subjecting the polyester textiles to film formation and shaping in water bath, and performing high-temperature baking; step 4, washingthe polyester textiles in the alcohol organic solvent until the polyvinyl butyral on the surfaces of the polyester textiles is dissolved to obtain dyed finished products. The method has the advantages that the polyvinyl butyral serves as a carrier of disperse dye, so that the dispersion stability is high, poison and harm are avoided, and safety, energy conservation, cleanness and environmental protection are realized; the dyeing method has a short process and a high dyeing speed, damage to polyester fibers after dyeing is small, water for film formation and shaping can be recycled, and energyconservation and emission reduction are achieved.

Owner:WUHAN TEXTILE UNIV

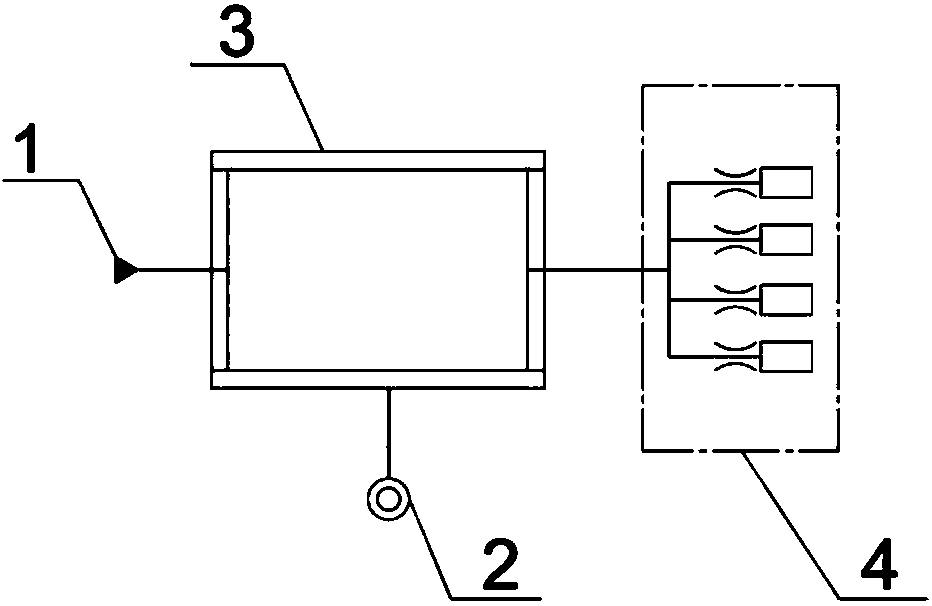

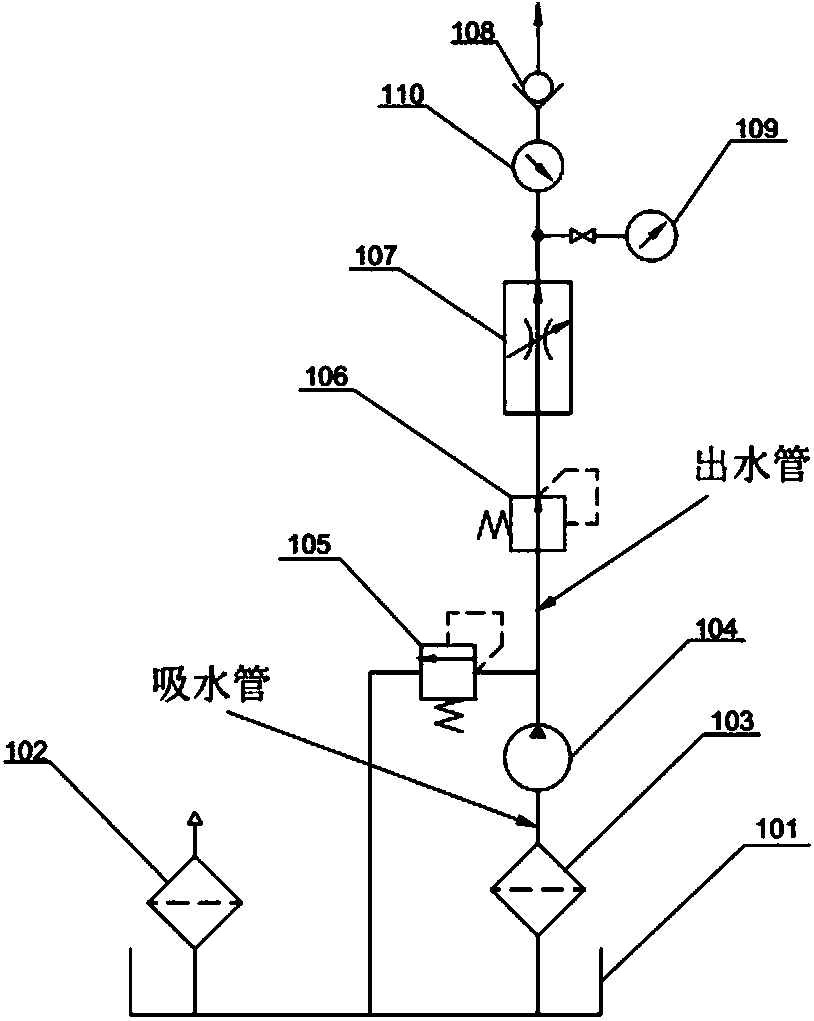

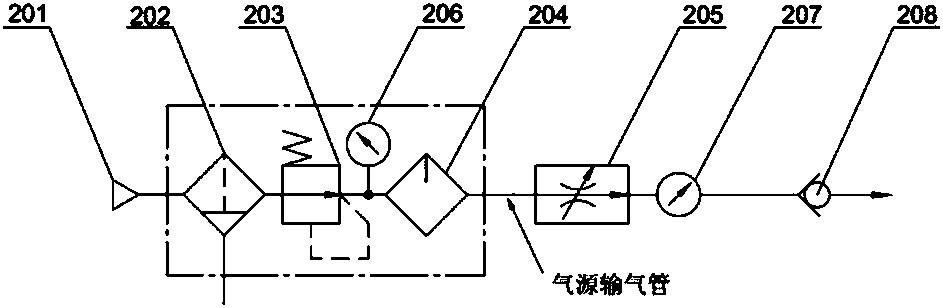

Cavitation rust-removing device

PendingCN108554895AImprove work efficiencyImprove the quality of workCleaning using liquidsShock wavePressure system

The invention belongs to the technical field of rust removing device, in particular to a cavitation rust removing device, which comprises a hydraulic system, an air pressure system and a cavitation generator, wherein both the hydraulic system and the air pressure system are communicated with the cavitation generator, and high-pressure liquid can be provided through the hydraulic system, by means of the air pressure system, high-pressure gas can be provided, the high-pressure liquid can be mixed with the high-pressure gas through the capitations generator, the cavity generator is communicated with a damping nozzle, and the mixture can be ejected through the damping nozzle.The cavitation generation is jointly controlled by a hydraulic system and a pneumatic system, a special cavitation generator is utilized, the convection field is analyzed to generate cavitation bubbles, the bombardment action of the shock wave formed by the bubble burst on the metal surface is generated, the purpose ofpeeling and cleaning the rust corrosion layer on the metal surface can be achieved.This method of removing rust by the principle of cavitationutilizes the inevitable cavitation phenomenon in the hydraulic system, so that the cavitation phenomenon can be changed into profit, and the purpose of cleaning is achieved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

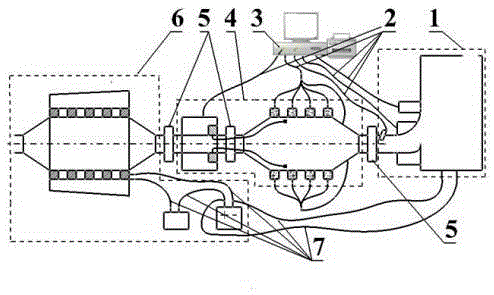

Thermal performance detection device of heat exchanger

InactiveCN105301046AClean and environmentally friendlyWithout losing independenceMachine part testingMaterial heat developmentEnvironmental resistanceEvaluation result

The invention provides a thermal performance detection device of a heat exchanger. The thermal performance detection device comprises a heat flow generator assembly, signal harnesses, a computer controller, a heat exchanger test board assembly, pipe opening connectors, a waste heat recoverer assembly and power lines. Each pipe opening connector is a device, wherein the pipe diameter at the two ends of the pipe opening connector can be adjusted; the heat flow generator assembly and the heat exchanger test board assembly transmit signals with the computer controller through the signal harnesses; the heat flow generator assembly processes external air into gas phase heat fluid at certain temperature and flow speed under the instruction of the computer controller and then guides the heat fluid to the heat exchanger test board assembly, the heat exchanger test board assembly measures the temperature of a test region on the outer wall of a heat exchanger and the flow speed of the internal air flow, sends the temperature and the flow speed to the computer controller in the mode of signals and gives out an evaluation result, and finally remaining heat flow enters the waste heat recoverer assembly for being recovered. The thermal performance detection device detects the thermal performance of the heat exchanger quite well and has the advantages of being clean, environmentally friendly, safe, efficient, economical, durable and the like.

Owner:SHENYANG LIGONG UNIV

Clean and environment-friendly production method for methionine hydroxyl analogue

InactiveCN109232336ASolve inseparableHigh purityOrganic compound preparationSulfide preparationOrganic solventMethionine hydroxy analog

The invention relates to a clean and environment-friendly production method for a methionine hydroxyl analogue, aiming at solving the problems in a traditional production technological method that themethionine hydroxyl analogue and ammonium salt are difficult to separate and more methionine hydroxyl analogues are carried in the byproduct ammonium salt; the purity of the obtained ammonium salt ishigh; in a whole process, less odor is generated; the whole production process is safe, clean and environmentally friendly, and nearly no wastewater is discharged; the problem of extracting by utilizing an organic solvent in a traditional production technology is solved or the problem that a mixture of the methionine hydroxyl analogue and the ammonium salt are concentrated at high temperature sothat the methionine hydroxyl analogue is decomposed to generate odorous gas is solved; the content of a monomer in an obtained product is greater than that of a traditional production technology and the quality of the product is relatively high.

Owner:LUFENG TIANBAO PHOSPHORUS CHEM CO LTD

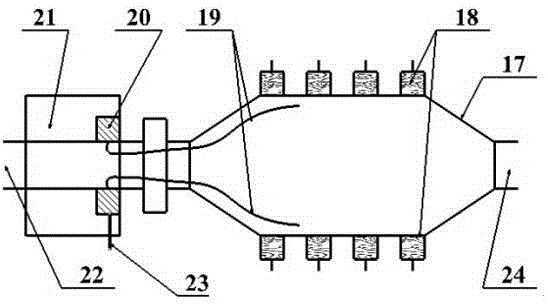

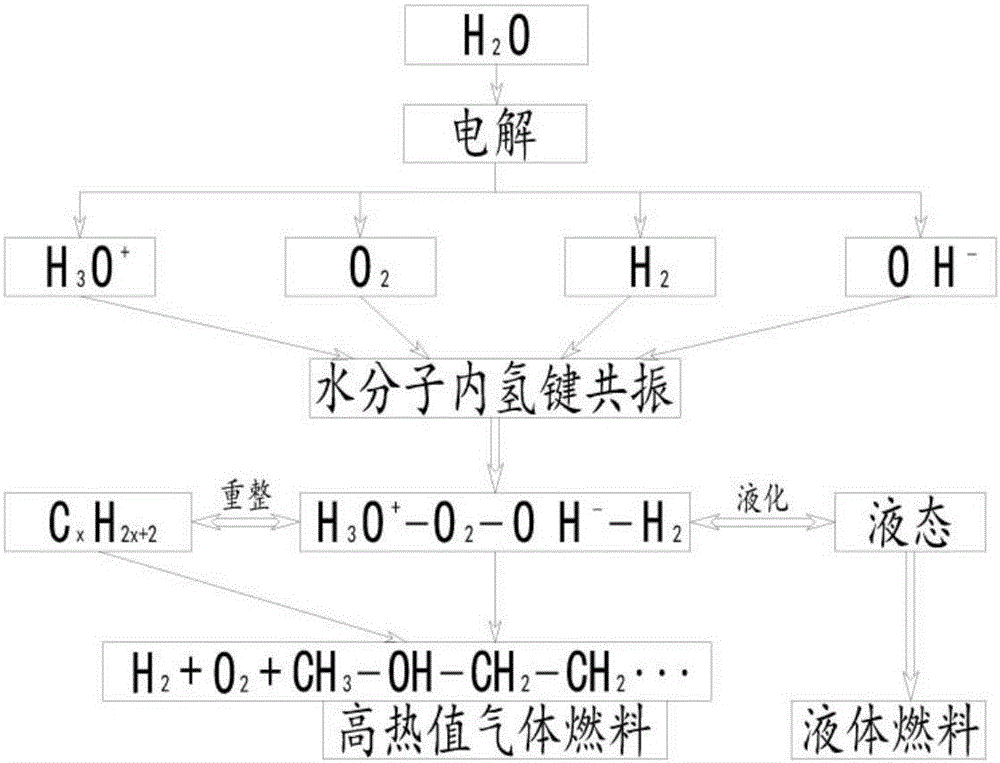

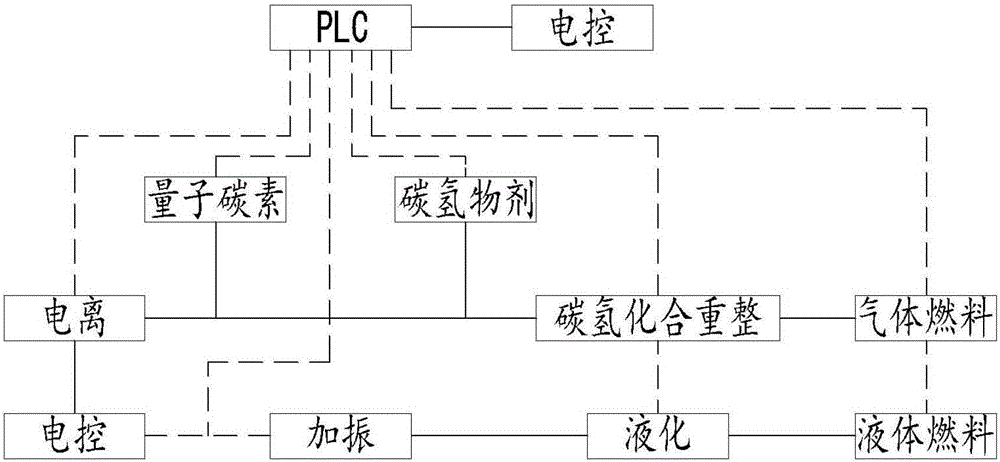

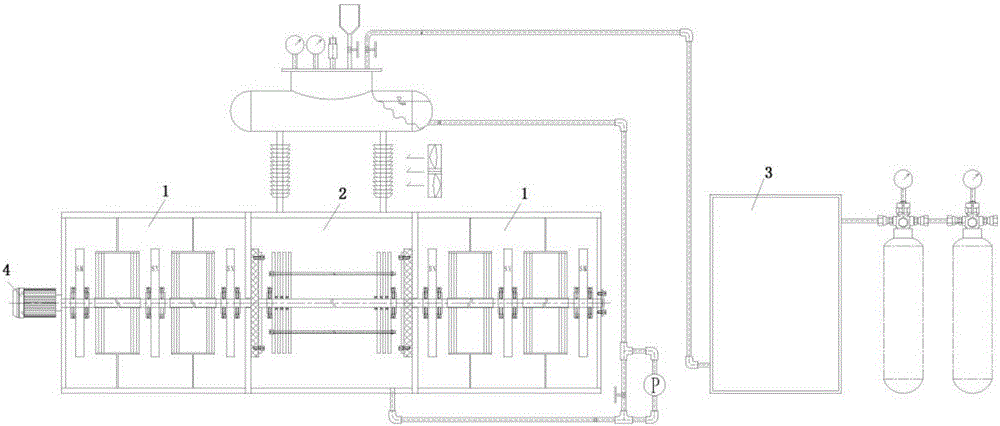

Fuel gas reformer and fuel gas preparation method

InactiveCN106118769AImprove securitySafe and Stable CombustionCellsGaseous fuelsHydrogenElectrolysis

The invention relates to a fuel gas reformer and a method, belongs to the field of novel energy, and in particular relates to a fuel gas reformer and a fuel gas preparation method. According to the fuel gas reformer and the fuel gas preparation method, oxygen, hydrogen and water generated from electrolysis form molecular groups in a molecular bonding manner through water intramolecular hydrogen bond resonance, and a fuel gas of a high heat value is prepared by reforming the molecular groups by using a package reforming liquid. The fuel gas of the high heat value, which is prepared by using the fuel gas reformer and the fuel gas preparation method, is good in security, easy to store, high in heat value and free of environment pollution.

Owner:YULINGHUA TECH CO LTD

Industrial solid waste constant energy environmental-protection fuel

The invention discloses an industrial solid waste constant energy environmental-protection fuel containing calcium carbide furnace dust, calcium carbide slag, fly ash and a reductant-oxidant, wherein based on 100 parts by weight of the calcium carbide furnace dust, the content of the calcium carbide slag is 72-200 parts by weight, the content of the fly ash is 35-85 parts by weight, and the content of the reductant-oxidant is 30-85 parts by weight. A large amount of industrial solid wastes can be consumed per year, the prepared industrial solid waste constant energy environmental-protection fuel has the advantages of full combustion and high calorific value, and the calorific value is more than 40 MJ / kg and is obviously increased compared with that of standard fire coal. At the same time, the fuel also has the characteristics of cleanness, environmental protection and low cost, can be used as a fire coal substitute for use in coal-fired boilers, overcomes the recycling problem of a large amount of industrial solid wastes in the prior art, and besides, creates economic benefits.

Owner:ELION RESOURCE GROUP +1

An electrode based on a flexible polyester wire substrate, a preparation method thereof, and a wearable supercapacitor

ActiveCN109087817ALarger specific capacityIncrease the areaHybrid capacitor electrodesHybrid/EDL manufacturePolyesterYarn

The invention belongs to the technical field of supercapacitors, in particular to an electrode based on a flexible polyester wire substrate, a preparation method thereof and a wearable supercapacitor.The invention provides a flexible polyester wire substrate, comprising: treated polyester wire and a metal with catalytic activity; the catalytically active metal is bonded to the surface of the treated polyester yarn. The flexible polyester filament substrate provided by the invention takes polyester filament as raw material, has wide raw material source, is easy to obtain, and has the advantages of simple processing technology, low price and green environmental protection. The treated polyester wires have porous structure, large specific capacity and specific surface area, good compatibility with catalytically active metals, and it is easy to grow current collector such as a nickel layer on the surface of the flexible polyester wire substrate, which is convenient for the subsequent preparation of electrodes.

Owner:GUANGDONG UNIV OF TECH

Industrial heavy oil stain cleaning agent and preparation method thereof

InactiveCN110257189AGood rust protectionLow flash pointOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsCleansing AgentsSolvent

The invention discloses an industrial heavy oil stain cleaning agent and a preparation method thereof. The cleaning agent comprises following components in percentage by weight: 70.0 to 90.0% of aromatic hydrocarbon free solvent oil (D80); 1.0 to 10.0% of a Mannich base cleaning agent (RF1202); 1.0 to 5.0% of vinyl succinate (T747A), and 5.0 to 10.0% of methyl nylon acid. The cleaning agent can remove impurities on the surface of mechanical parts and metal parts such as oil stains, grease, dirt, metal chips, dust, and the like; the cleaning effect is good, the physical and chemical properties are good; moreover, the cleaning agent does not have pungent smell, is harmless to human body, and is noncorrosive; hands can contact with the cleaning agent directly, and the cleaning agent will not damage human body or equipment.

Owner:张娟娟

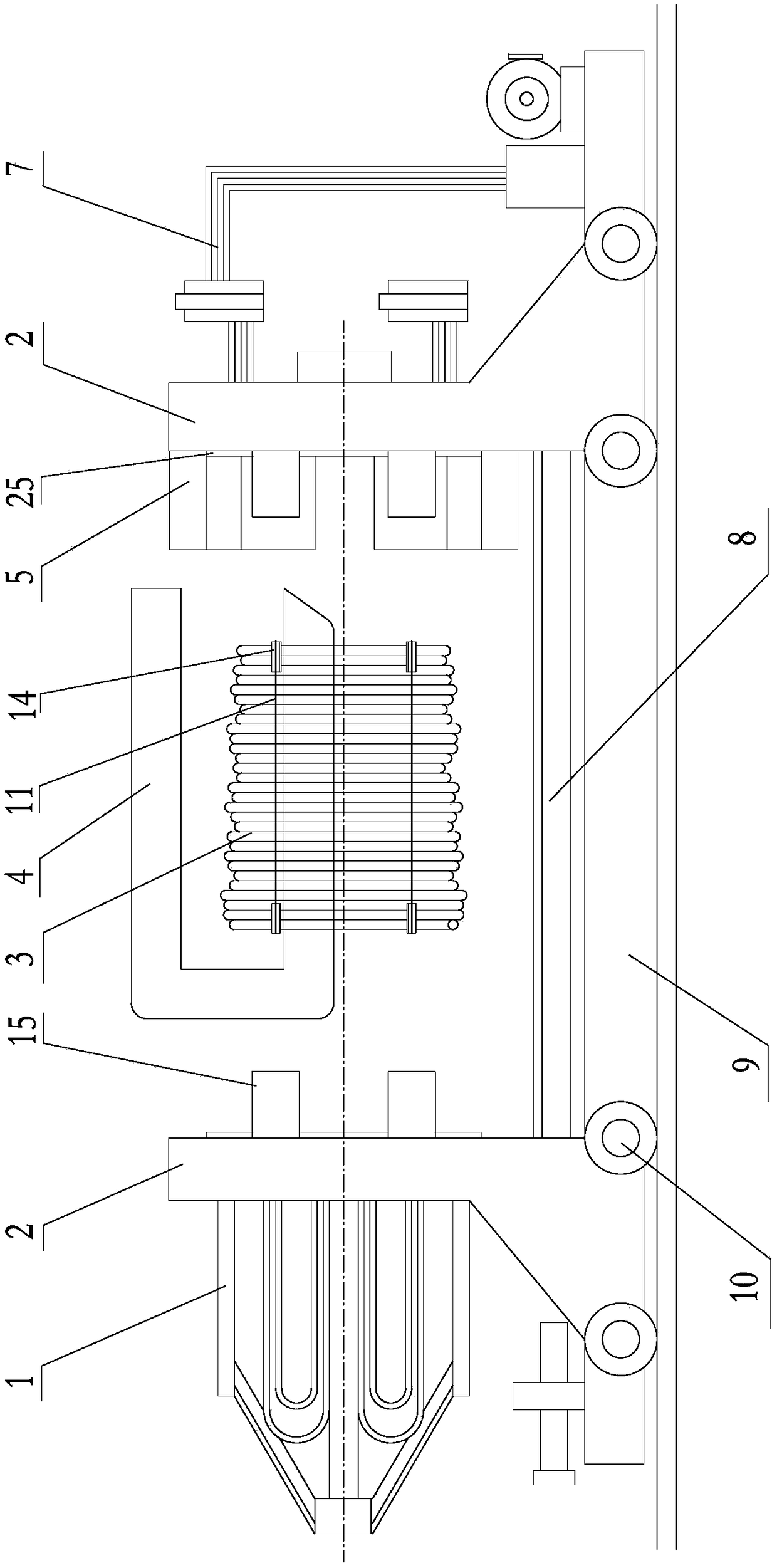

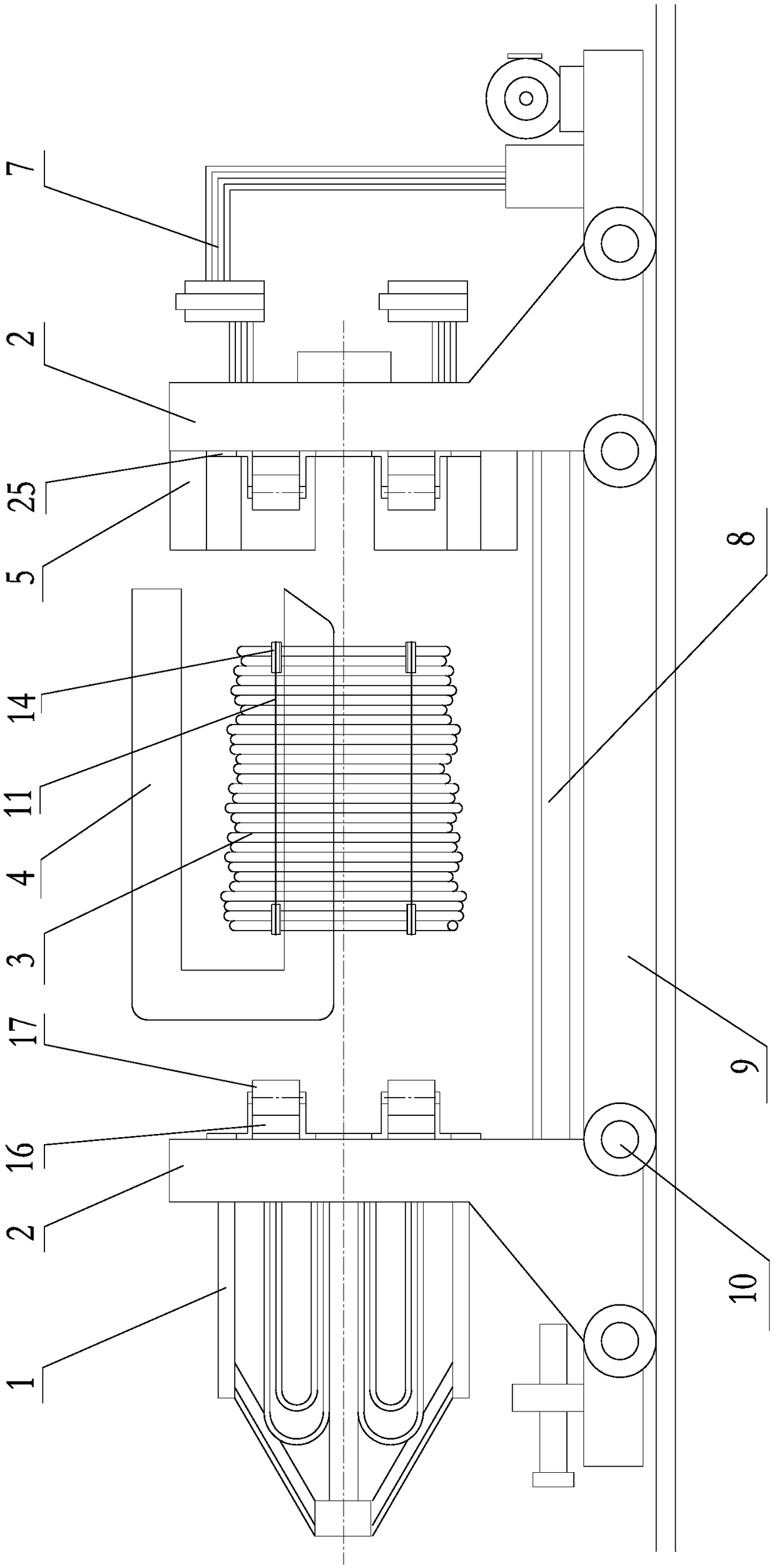

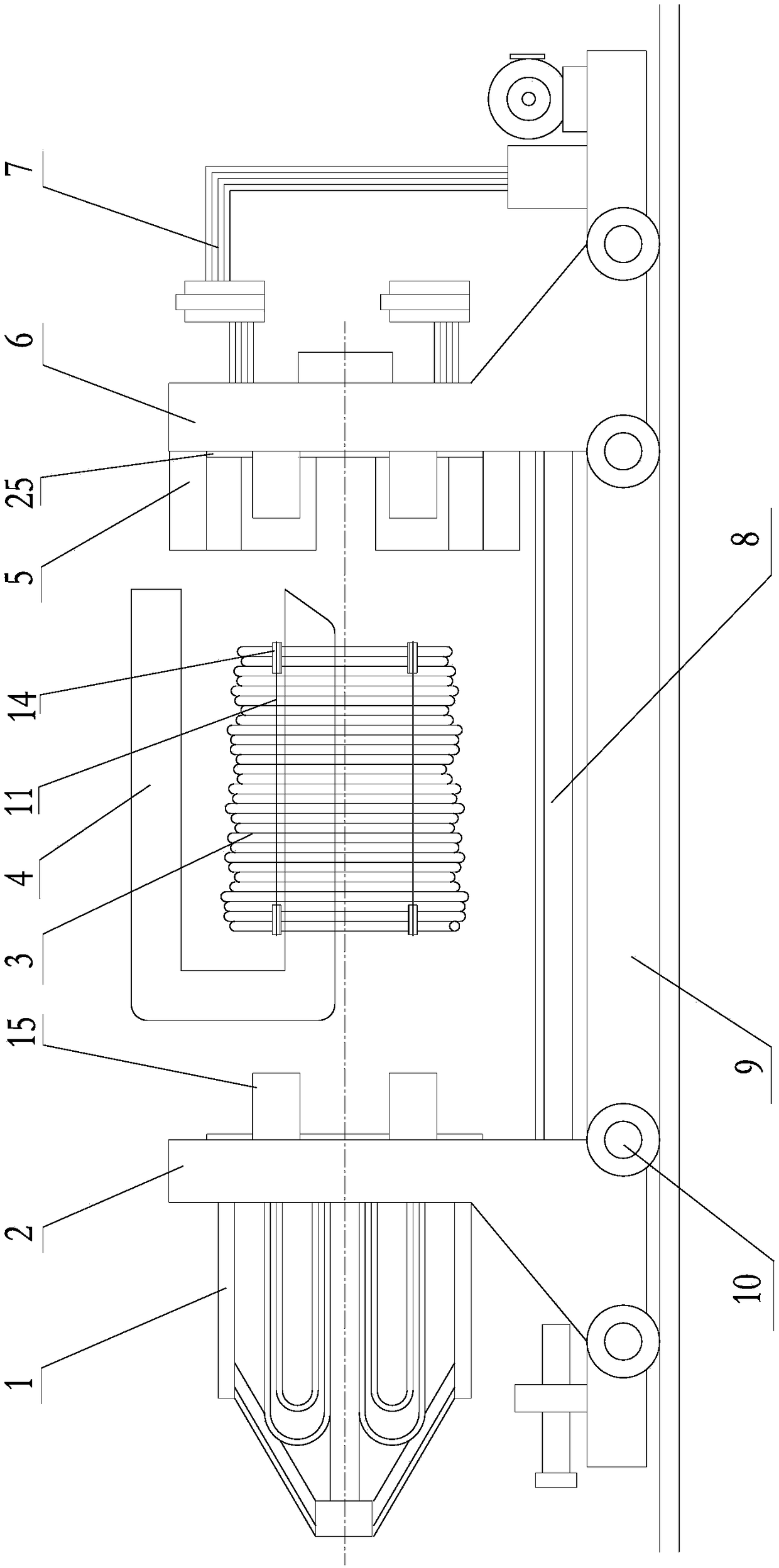

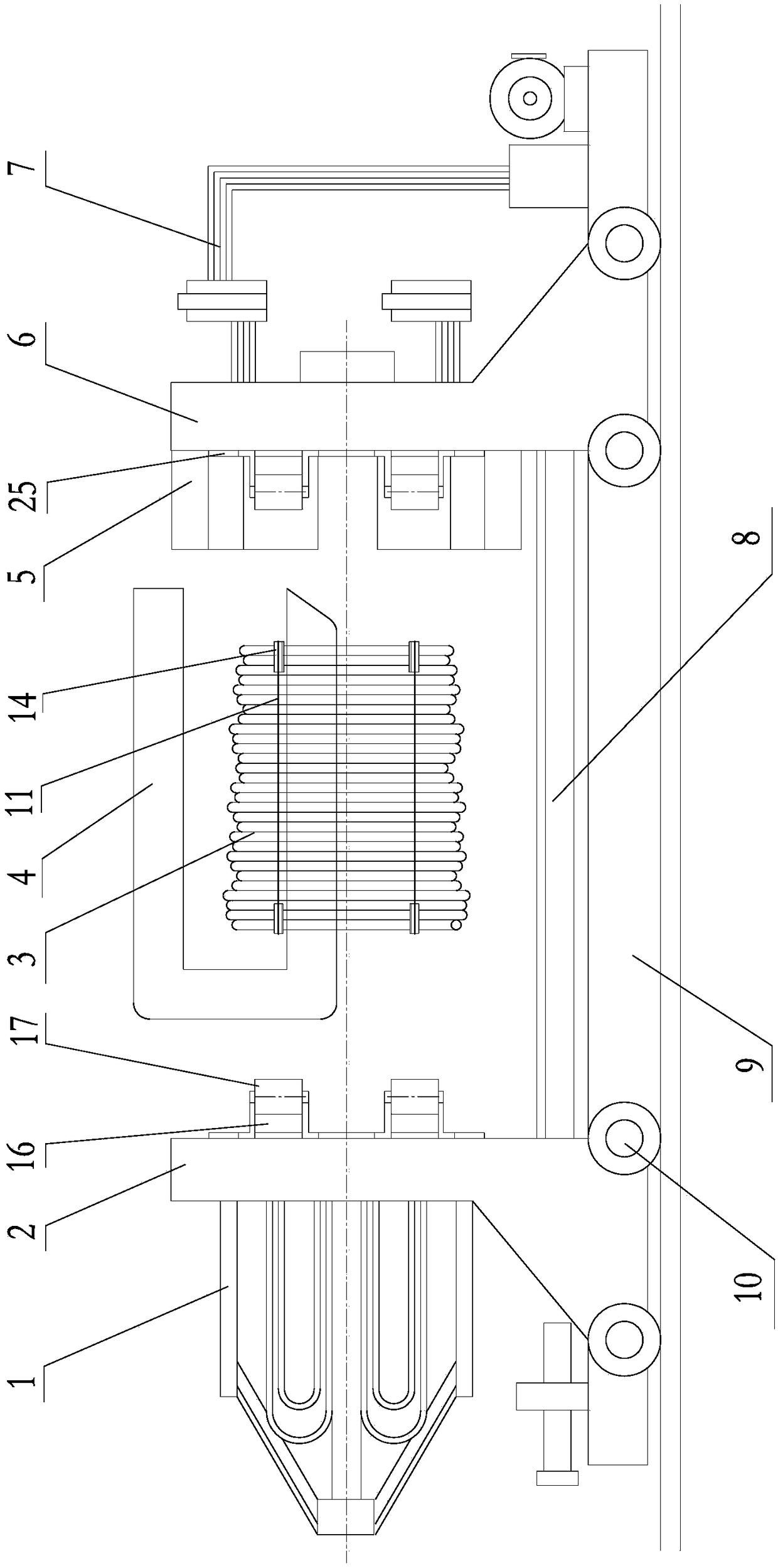

Gasket placement improved mechanism of high speed wire rod baling machine

InactiveCN108773541AClean and environmentally friendlyRealize environmental protectionBundling machine detailsFerrous metallurgyChemical synthesis

The invention relates to an improved mechanism of a machine tool in the baling process for wire rods formed by steel rod machining in the field of ferrous metallurgy, in particular to a gasket placement improved mechanism of a high speed wire rod baling machine. Continuous pushing mechanisms (15) for gaskets (14) are arranged at the four diagonal portions of a pressing plate (2); the gaskets (14)are metal sheets or chemical synthesis sheets with the hardness of the contact faces smaller than that of steel; the multiple gaskets (14) are pushed to penetrate through a channel formed by a filingprevention disk (25) to reach the positions of wire grooves (18) in the pressing plate (2) one by one by the continuous pushing mechanisms (15), and the binding and winding directions of the gaskets (14) are consistent with the directions of the wire grooves (18); the continuous pushing mechanisms (15) are mounted on the pressing face of the pressing plate (2) or the pressing face and the side face of the pressing plate (2) or the pressing face of the pressing plate (2) and an extending plate outside the pressing face. The pure machine operation improved structure different from an existing gasket placement mode is provided at the first time, the labor intensity and the dangerousness of manual gasket placement are lowered, the operation speed, efficiency, quality and effect are greatly improved, and urgent application and popularization value is achieved.

Owner:SHANGHAI WINLONG ENERGY CONSERVATION & ENVIRONMENTAL PROTECTION TECH CO LTD

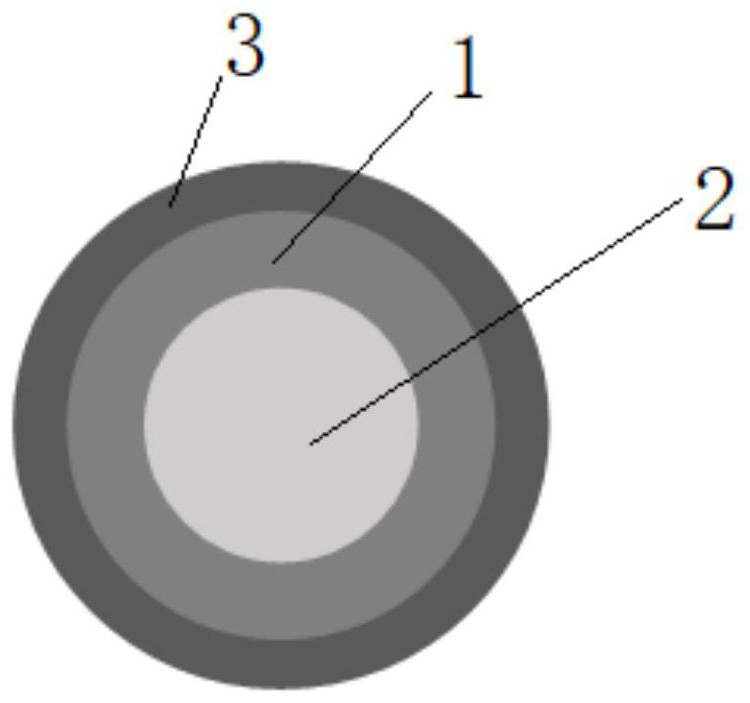

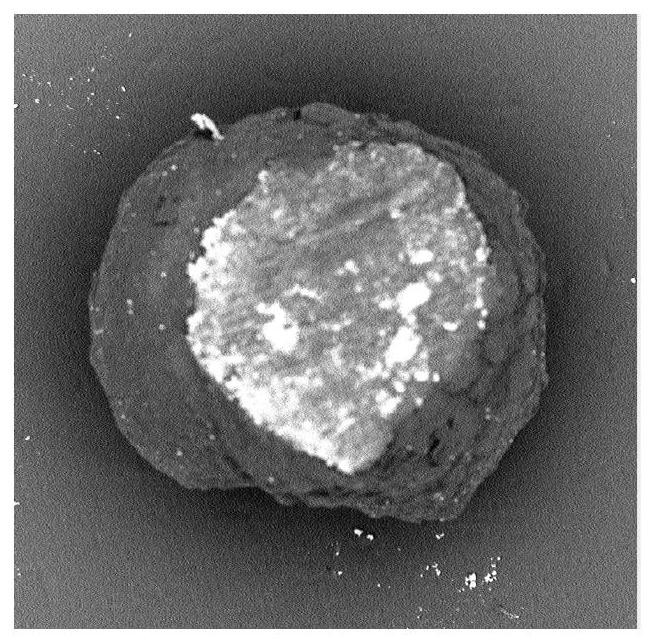

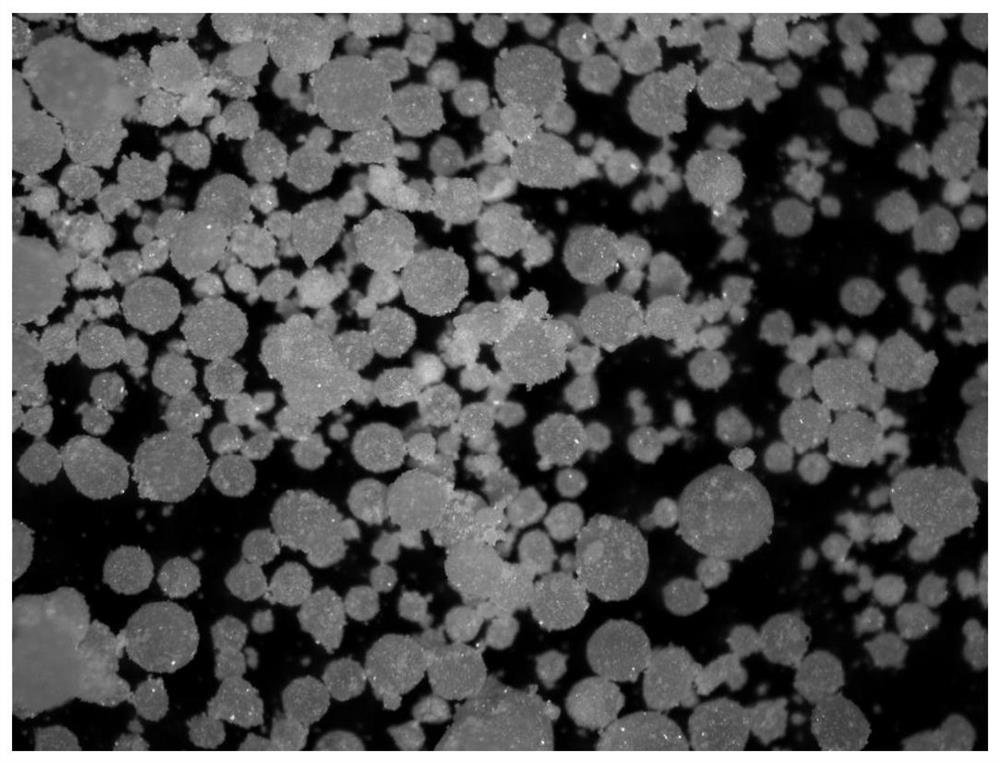

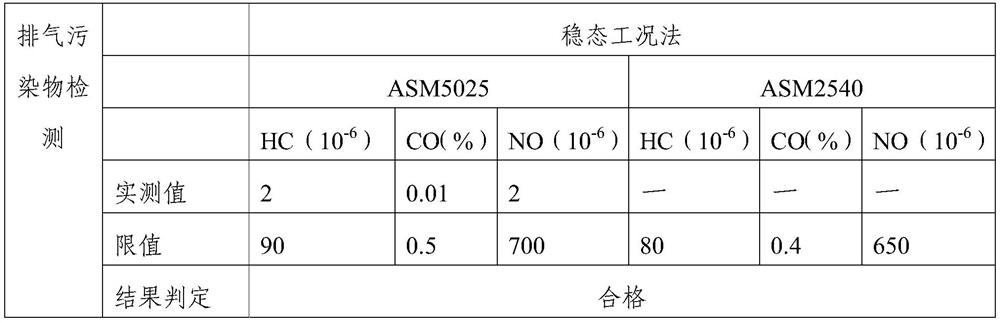

Cement paste temperature control self-repairing microcapsule and preparation method thereof

InactiveCN112645634AImprove safety performanceLow costMicroballoon preparationMicrocapsule preparationPolymer chemistryAlkane

The invention provides a cement paste temperature control self-repairing microcapsule which is of a spherical particle structure, the microcapsule comprises a capsule core and a capsule wall wrapping the capsule core, the capsule core and the capsule wall are bonded through an adhesive layer, the adhesive layer is made of epoxy resin, the capsule core is made of a paraffin and alkane mixture, and the capsule wall is made of calcium carbonate. The invention further provides a preparation method of the cement paste temperature control self-repairing microcapsule. The cement paste temperature control self-repairing microcapsule prepared by the invention is simple in preparation process, can be industrially produced in batches, and is high in cleanness and environmental friendliness in the production process.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Preparation of carboxymethyl chitosan quaternary ammonium p-toluenesulfonate

The invention relates to a preparation method of p-toluene sulfonic acid quaternary amine of carboxymethyl chitosan, which is characterized by comprising the following steps of: under the protection of nitrogen, adding potassium carbonate, acetonitrile and methyl p-toluene sulfonic acid, controlling the temperature of 15 DEG C+3 DEG C, dripping acetonitrile solution of carboxymethyl chitosan, carrying out mechanical stirring for 5 minutes under room temperature, rising temperature to 83 DEG C, and carrying out violently backflow reaction for about 22 hours. The preparation method has the following advantages of having lower price and easy obtaining for reaction materials, mild reaction, simple condition, stability, easy production on scale and novel synthesis method, avoiding the use of highly toxic reagent of methyl iodide and dimethyl sulfate and the like, cleanness, environmental protection and greatly reducing hazard and toxicity; and the products has obvious leap in the properties of absorption and regeneration.

Owner:STATE GRID CORP OF CHINA +1

Kitchen heavy oil stain high efficiency cleaning agent

InactiveCN107189875AClean and environmentally friendlyImprove permeabilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsFiberAmylase

The invention discloses a kitchen heavy oil stain high efficiency cleaning agent. The kitchen heavy oil stain high efficiency cleaning agent comprises, by weight, 1 to 5 parts of chamomile extracted liquid, 1.5 to 6.5 parts of sodium alkyl benzene sulfonate, 0.5 to 7.5 parts of an aliphatic alcohol amide, 1 to 6 parts of sodium carbonate, 2 to 6 parts of ethylene glycol monobutyl ether, 1.5 to 6.5 parts of triethanolamine, 2 to 9 parts of benzotriazole, 1.5 to 7.5 parts of alkylphenol polyoxyethylene, 0.1 to 2.5 parts of sodium monomaleate, 1 to 5 parts of a anionic surfactant, 1.5 to 6.5 parts of bamboo fiber powder, 1 to 5 parts of ginkgo extracted liquid, 5 to 15 parts of Chinese honeylocust fruit extracted lilquid, 0.5 to 3.5 parts of a penetrant, 0.5 to 2.5 parts of amylase, and the balance purified water. The kitchen heavy oil stain high efficiency cleaning agent can be used for cleaning, is friendly to the environment, is excellent in permeability, is nontoxic and harmless, is phosphorus-free, and is high in cleaning efficiency; and corrosion of kitchen equipment and skin damage are not caused in cleaning process.

Owner:SUZHOU LOTTE CHEM TECH

Method for preparing lignin in use of corncob residues as raw materials

The invention provides a method for preparing lignin in use of corncob residues as raw materials; corncob residues of leftovers in xylose production are adopted as the raw materials and subjected to the processes such as alkaline liquid soaking reaction, nanofiltration and concentration, spray drying or acidification filtration to prepare alkaline lignin products or acidic lignin products; the production process is simple and the product quality is stable. The preparation method solves the problems such as low utilization rate of xylose resources, single products and high production cost existing in the xylose industry and satisfies the requirements of changing the economic growth mode advocated in China, reducing production cost and protecting the environment.

Owner:FUTASTE PHARM CO LTD

Universal methanol fuel for vehicles and preparation method thereof

InactiveCN112251264AImprove powerRich sourcesLiquid carbonaceous fuelsFuel additivesMethanol fuelGasoline

The invention discloses a universal methanol fuel for vehicles and a preparation method thereof, and relates to the technical field of fuels. The fuel comprises the following raw materials by weight:40-60 parts of methanol, 20-30 parts of C5 raw materials, 6-8 parts of MTBE, 9-14 parts of aromatic hydrocarbon, 8-12 parts of petroleum ether, 0.005-0.015 part of a preservative, 1-3 parts of an additive, and 1-3 parts of a catalytic synthesis agent. Compared with an existing gasoline product, the universal methanol fuel for the vehicle has the advantages that under the conditions of the same vehicle model and the same fuel ratio, the dynamic property and mileage of the universal methanol fuel are superior to those of gasoline, tail gas emission is far lower than that of the gasoline, the universal methanol fuel can completely replace the gasoline, and the problems of petrochemical energy shortage, environmental pollution and the like can be solved.

Owner:邵金平

Flower pot

InactiveCN103125297AReal-time detection of humidityEliminates manual watering stepsSelf-acting watering devicesReceptacle cultivationEngineeringElectric control

The invention relates to a flower pot which comprises a flower pot body (1), an external water pipe (6), a control module (2), a humidity sensor (3), an electric control valve (4) and a power supply (5), wherein the humidity sensor (3), the electric control valve (4) and the power supply are respectively connected with the control module (2). The power supply (5) supplies power to the devices through the control module (2), the electric control valve (4) is arranged on a water outlet of the external water pipe (6) and is arranged above the flower pot body (1), the humidity sensor (3) is arranged in the flower pot body (1) to detect humidity in the flower pot body (1) in real time and sends a detecting result to the control module (2), and the control module (2) controls work of the electric control valve (4) in real time according to a monitoring result. According to the flower pot, humidity situation of soil in the pot can be detected in real time, plants in the flower pot can be automatically flowered according to the detecting result, and steps of manual flowering are omitted.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com