Method for quickly dyeing polyester textiles

A rapid dyeing and textile technology, applied in the field of textile printing and dyeing, can solve the problems of high equipment requirements, frequent temperature changes, large water consumption, etc., achieve the effects of short process, fast dyeing speed, and reduced discharge of waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for fast dyeing of polyester textiles, said method comprising the following steps:

[0037] Step 1: Preparation of dyeing paste

[0038] Mix disperse dyes, penetrants, dispersants and swelling agents in alcoholic organic solvents in proportion, stir mechanically, and slowly add polyvinyl butyral during stirring until the polyvinyl butyral is fully dissolved to obtain dyeing paste ;

[0039] Step 2: Dyeing Polyester Textiles

[0040] Placing the polyester textile in the dyeing paste prepared in step 1;

[0041] Step 3: Shaping of Polyester Textiles

[0042] The polyester textile dyed in step 2 is placed in a water bath to form a film and then baked at a high temperature;

[0043]Step 4: Postprocessing

[0044] Washing the polyester textiles shaped in step 3 in an alcoholic organic solvent until the polyvinyl butyral film on the surface of the polyester textiles is dissolved to obtain a finished dyed product.

[0045] In the above-mentioned embodiment, the ...

Embodiment 2-9

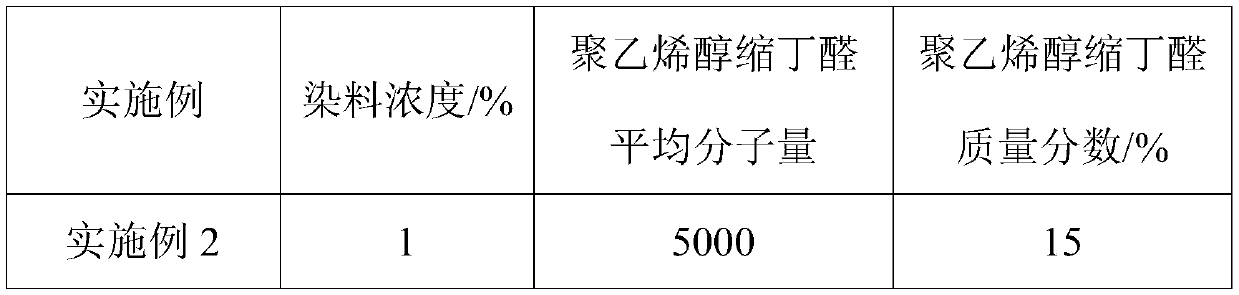

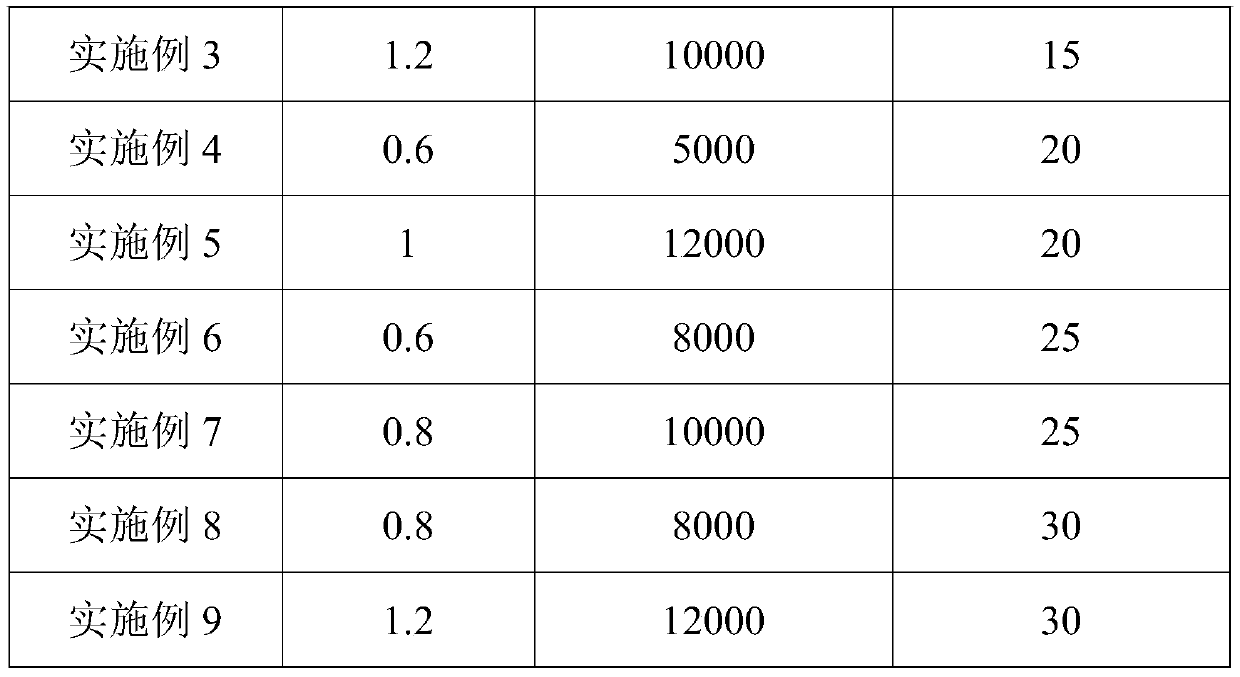

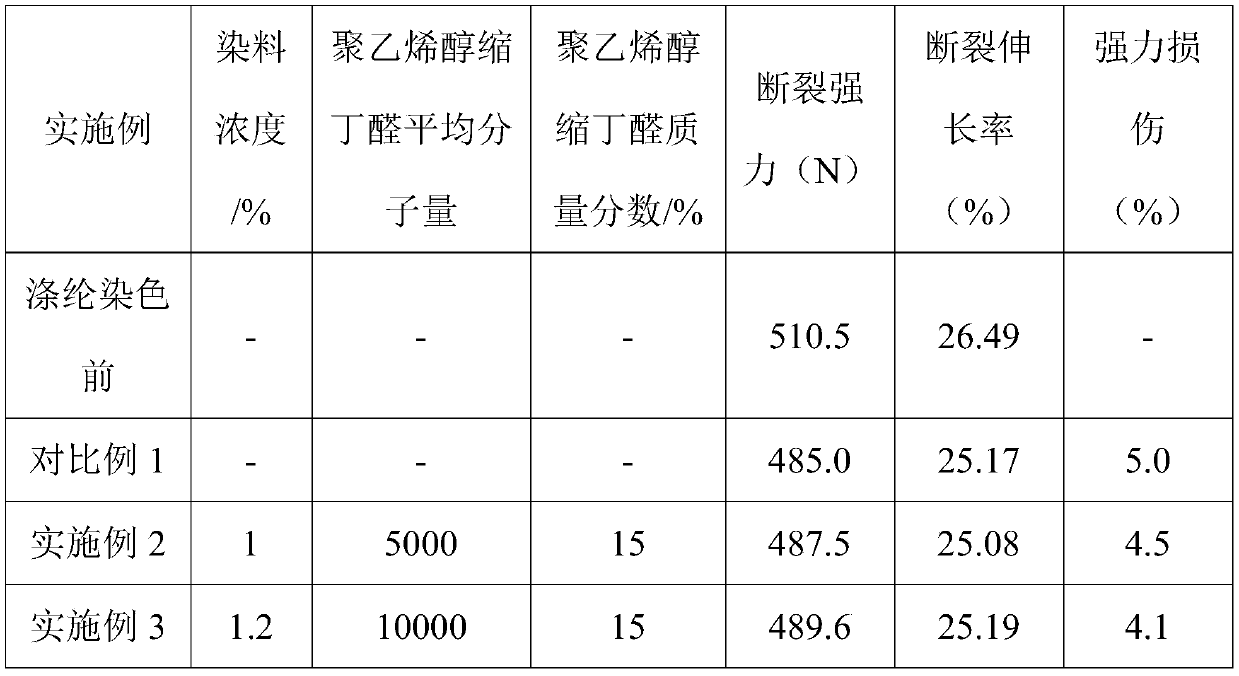

[0067] A kind of method for fast dyeing of polyester textiles provided by embodiment 2-9, wherein said dyestuff concentration and the molecular weight of polyvinyl butyral carrier and the mass fraction of polyvinyl butyral are as shown in Table 1, all the other and Embodiment 1 is consistent. The results of the polyester fiber breaking strength, elongation at break and strength damage after dyeing are shown in Table 2.

[0068] Table 1 Mass fraction and average molecular weight of different dye concentrations and carrier vinyl butyral PVB

[0069]

[0070]

Embodiment 10-17

[0078] A method for rapid dyeing of polyester textiles provided in Examples 10-17, wherein the concentration of the penetrating agent, the concentration of the dispersant, and the concentration of the swelling agent are shown in Table 3, and the rest are consistent with Example 1. The results of the polyester fiber breaking strength, elongation at break and strength damage after dyeing are shown in Table 4.

[0079] Table 3 Different penetrant concentration, dispersant concentration and expansion agent concentration

[0080] Example Penetrant (%) Dispersant(%) Expansion agent (%) Example 10 0.3 0.08 0.10 Example 11 0.3 0.09 0.15 Example 12 0.4 0.09 0.20 Example 13 0.4 0.1 0.15 Example 14 0.5 0.1 0.10 Example 15 0.5 0.08 0.20 Example 16 0.6 0.11 0.05 Example 17 0.6 0.11 0.05

[0081] As can be seen from Table 4, with the method for fast dyeing of a kind of polyester textile of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com