Thermal performance detection device of heat exchanger

A detection device and heat exchanger technology, applied in the direction of measurement device, air heater, fluid heater, etc., can solve the problems of high energy consumption, ineffective utilization of air waste heat, imperfect performance and evaluation methods, etc., and achieve economical The effect of durable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

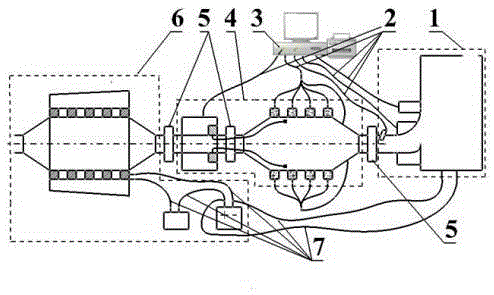

[0026] Such as Figure 1 to Figure 7 As shown, the heat exchanger thermal performance detection device includes heat flow generator assembly 1, signal harness 2, computer controller 3, heat exchanger test bench assembly 4, nozzle connector 5, waste heat recovery assembly 6 and power cord7. The nozzle connector 5 is a device that can adjust the size of the pipe diameter at both ends, and is used for the connection between the heat flow generator assembly 1, the heat exchanger test bench assembly 4 and the waste heat recovery device assembly 6; The heat flow generator assembly 1 and the heat exchanger test bench assembly 4 transmit signals with the computer controller 3 through the signal wire harness 2 .

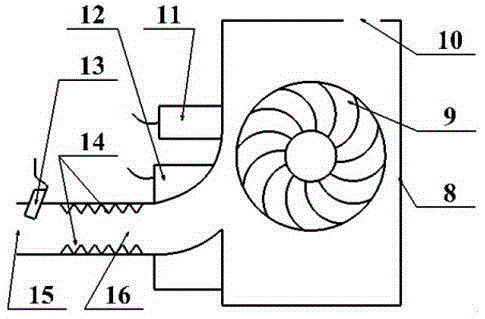

[0027]The heat flow generator assembly 1 is located at the front end of the thermal performance detection device of the heat exchanger, including a heat flow generator box 8, a blower turbofan 9, an air inlet 10, a blower turbofan speed controller 11, a fluid temperature con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com