Tungsten alloy micro-needle electrode capable of limiting piercing depth, preparation method thereof, and blood glucose monitoring device

A microneedle and electrode technology, applied in the field of biochemical analysis, can solve the problems of skin wound allergy, slender needle body, infection, etc., and achieve the effect of shortening the etching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

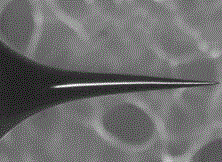

[0032] This embodiment provides a microneedle electrode with limited penetration depth, such as figure 1 and Figure 5 , including a microneedle body, the microneedle body includes a needle tip area 1 arranged at the front end of the micro needle body, and a boss area 2 arranged at the rear end of the needle tip area with a radius greater than that of the needle tip area.

[0033] Further, a transition area 3 is also provided between the boss area and the needle tip area; the radius of the transition area gradually increases from one end of the needle tip area to one end of the boss area.

[0034] Further, the microneedle body is made of tungsten copper alloy.

[0035] Further, the surfaces of the tip area and the transition area are covered with a sensitive layer; the sensitive layer is an electrode active material sensitive to glucose.

Embodiment 2

[0037] This embodiment provides a microneedle electrode with a limited penetration depth, including a microneedle body, the microneedle body includes a needle tip area disposed at the front end of the microneedle body, and further includes a boss disposed at the rear end of the needle tip area with a radius larger than the needle tip area Area.

[0038] Further, a transition area is also provided between the boss area and the needle tip area; the radius of the transition area gradually increases from one end of the needle tip area to one end of the boss area.

[0039] Further, the microneedle body is made of copper material.

[0040] Further, the surfaces of the tip area and the transition area are covered with a sensitive layer; the sensitive layer is an electrode active material sensitive to alcohol.

Embodiment 3

[0042] This embodiment provides a microneedle electrode with a limited penetration depth, including a microneedle body, the microneedle body includes a needle tip area disposed at the front end of the microneedle body, and further includes a boss disposed at the rear end of the needle tip area with a radius larger than the needle tip area Area.

[0043] Further, a transition area is also provided between the boss area and the needle tip area; the radius of the transition area gradually increases from one end of the needle tip area to one end of the boss area.

[0044] Further, the microneedle body is made of any one of platinum, silver, gold, copper, and tungsten.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com