Method for preparing freeze-dried excipient preparation in any shape and product of method

A technology of freeze-drying shape forming and arbitrary shape, which is applied in the direction of freeze-drying transportation, medical preparations of non-active ingredients, pharmaceutical formulas, etc., and can solve problems such as difficult multi-layer structure, single shape of preparation, single structure of preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] (a) add bilberry extract: pullulan = 5:1, add water to prepare a solution, centrifuge and degas, and obtain the stock solution 1 of the freeze-dried excipient;

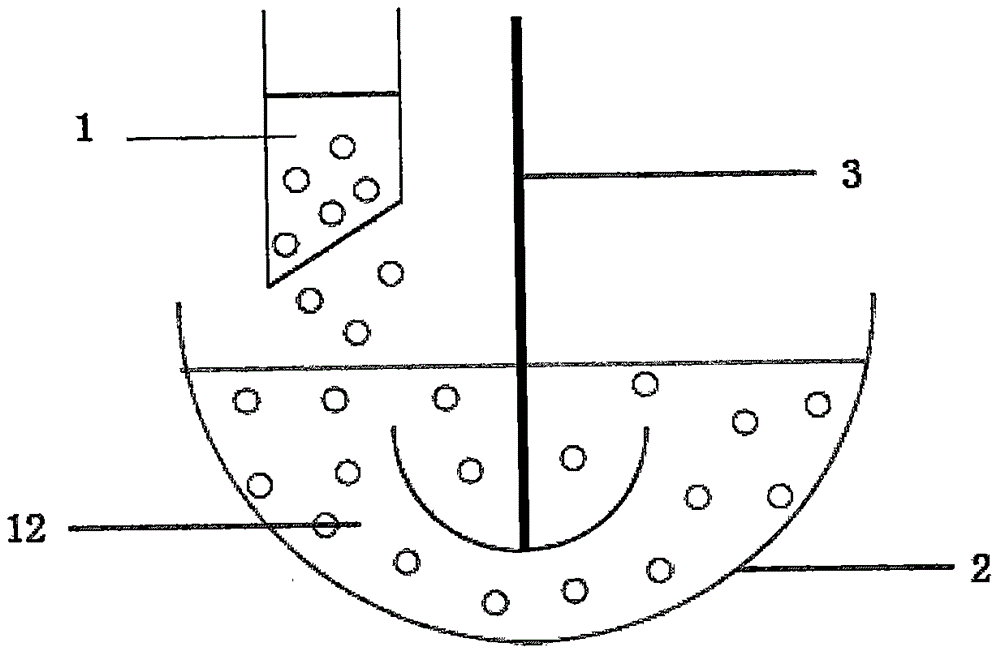

[0071] (b) Put the lyophilized excipient stock solution 1 into the container 2 to freeze, and cooperate with the agitator 3 to fully stir it into a smoothie-like lyophilized excipient stock solution 12;

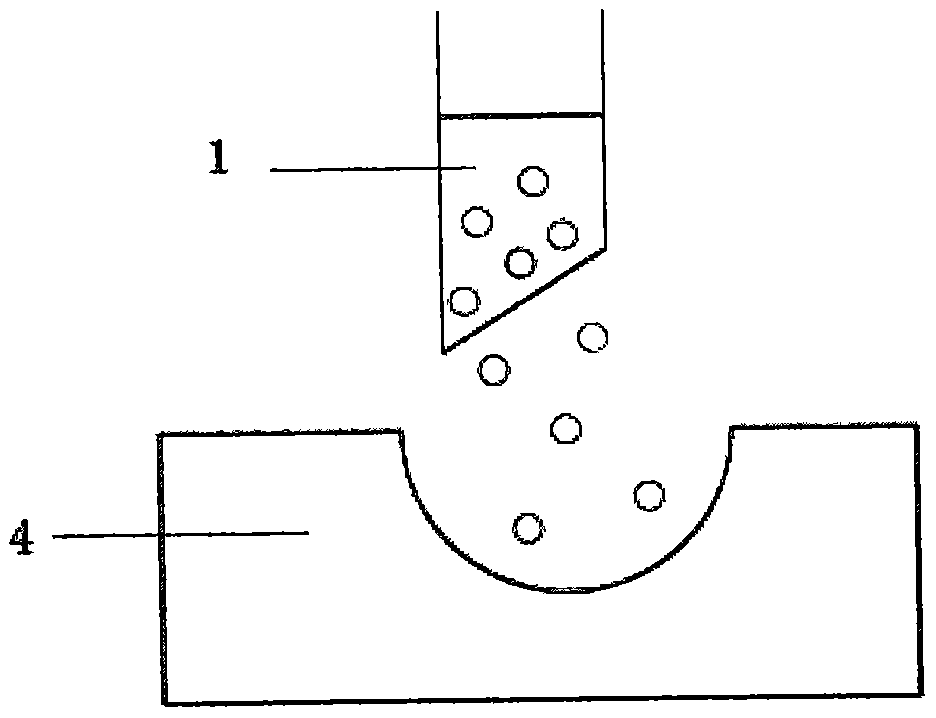

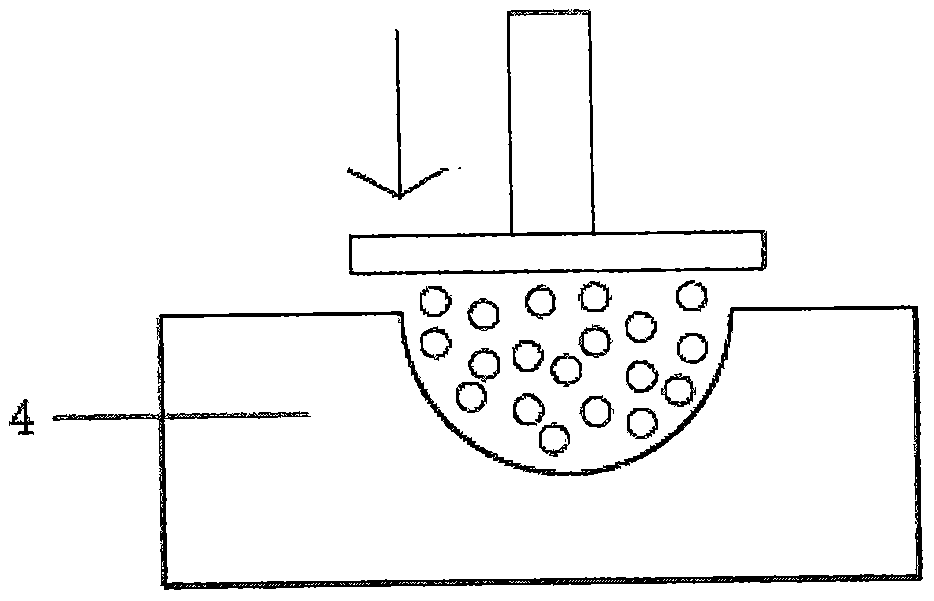

[0072] (c) Use a filling pump to fill the smoothie-like freeze-dried excipient stock solution 12 into the one-way release sheet mold 4, and apply a certain pressure to completely fill it in the mold 4 to form a mold with a diameter of 2.5 cm and a thickness of 2.5 cm. The shape of a tablet of 0.5 cm;

[0073] (d) Freeze-drying the mold and the smoothie therein, removing the solvent, to obtain a freeze-dried excipient;

[0074] (f) carry out internal packing, namely obtain cranberry solid instant drink.

Embodiment 2

[0076] (a) stirring rose extract: trehalose = 1:10 to form a solution, and vacuum degassing to obtain a stock solution of a freeze-dried excipient;

[0077] (b) Put the lyophilized excipient stock solution 1 into the container 2 to freeze, and cooperate with the agitator 3 to fully stir it into a smoothie-like lyophilized excipient stock solution 12;

[0078] (c) Use a filling pump to pack the smoothie-like freeze-dried excipient stock solution 12 into a spherical mold 4 consisting of two molds and two-way demoulding, and apply a certain pressure to completely fill it in the mold 4, so that Form the shape of a spherical pellet with a diameter of 3 cm;

[0079] (d) Freeze-drying the mold and the smoothie therein, removing the solvent, to obtain a freeze-dried excipient;

[0080] (e) Carry out internal packaging, and mix with water when using, promptly obtain the ready-to-mix type rose essence skin care product.

Embodiment 3

[0082] (a) Take pullulan: ginseng extract = 3: 1 solution as component one, take PC: Tween 80 = 5: 1 to prepare component two;

[0083] (b) Stirring and preparing solutions 1 and 2 respectively, and centrifugally degassing them to obtain stock solutions 101 and 102 of freeze-dried excipient preparations;

[0084] (c) Put the freeze-dried excipient stock solution 101 into a container 201 to freeze, and fully stir it with the agitator 3 to form a smoothie-like freeze-dried excipient stock solution 121; put the freeze-dried excipient stock solution 102 into the container 202 Freeze, and fully stir with the agitator 3 to form a smoothie-like freeze-dried excipient stock solution 122;

[0085] (d) Using a pipette pump, put the stock solutions 121 and 122 of the smoothie-like freeze-dried excipient preparation into the spherical mold 4 composed of two molds and bidirectional demoulding, and apply a certain external force to connect the two molds, Compress so that it forms the shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com