Method for preventing fiber breaking at root of hollow fiber ultrafiltration membrane

An ultrafiltration membrane and fiber technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problems of easy breakage of membrane filaments, decline in mechanical properties, and decrease in tensile strength of membrane filaments against breakage. The effect of wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

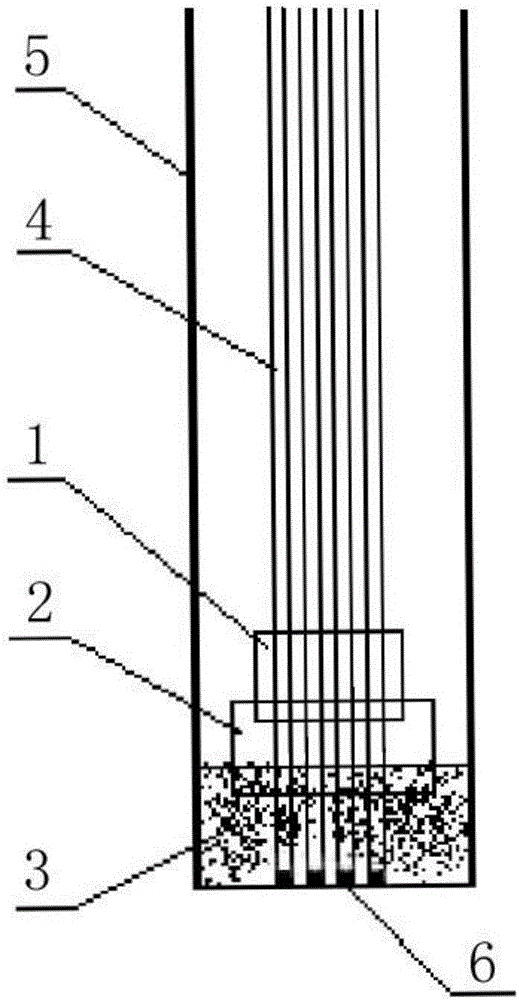

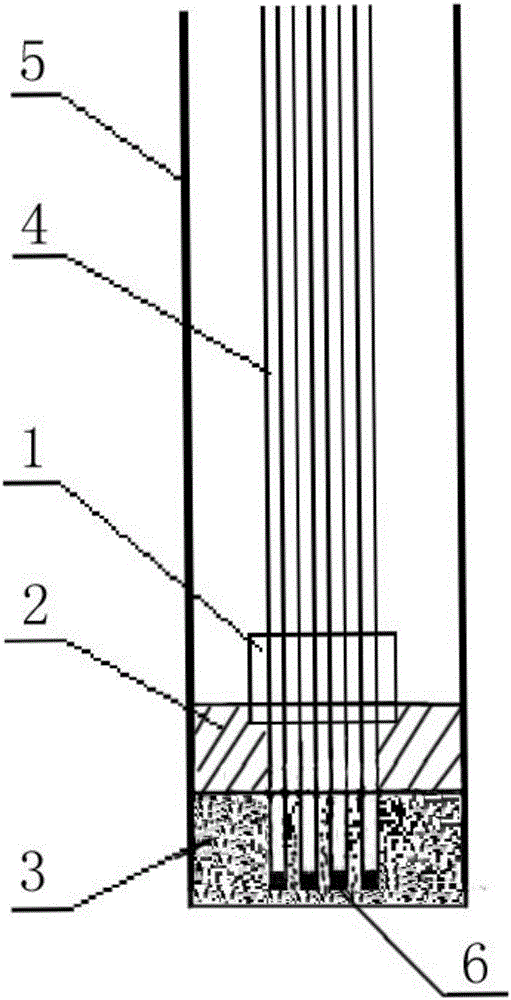

[0020] Cut the bottom of the root of the film tow with a circumference of about 20cm to be cast flat, plug the hole for 1-2mm with a known conventional method, and wrap a piece of self-adhesive coil with a diameter of 25cm*5cm*3.5mm and a Shore hardness of 90 tightly at a distance At 6cm from the end face of the plugging hole of the membrane tow, wrap another piece of self-adhesive coiled material of the same size on the membrane tow so that it is 3cm away from the end of the plugging hole of the membrane tow, overlapping with the aforementioned self-adhesive coil by 2cm, and then wrap the membrane tow Put it into the membrane module cylinder, put it into the suitable mold together, add epoxy resin adhesive to submerge the second layer of protection 2cm, remove the mold after the epoxy resin is cured, and spread the excess sealing material along the module cylinder resection.

Embodiment 2

[0022] Cut the bottom of the membrane tow with a circumference of about 20 cm to be cast flat, plug the hole for 1 to 2 mm by a known conventional method, and take a piece made of silica gel, polyethylene, polyvinyl chloride, polyurethane, polystyrene, etc. The viscoelastic plastic is coated with self-adhesive on one side, the size specification is 25cm*10cm*3.5mm, the Shore hardness is 20, the anti-adhesive release paper of the self-adhesive is torn off, and tightly wound on the distance Wrap another piece of viscous elastic plastic of the same size on the membrane tow at 10 cm from the end face of the membrane tow plugging hole so that it is 3 cm away from the end of the membrane tow plugging hole, and overlap with the aforementioned self-adhesive coil by 4 cm, and then wrap the membrane tow Put the membrane component cylinder into the suitable mold together, add epoxy resin adhesive to submerge the second protective layer by 1cm, remove the mold after the epoxy resin is cure...

Embodiment 3

[0024] Cut the membrane tow with a circumference of about 20cm to be cast flat, and plug the hole 1-2mm with a known method, and tightly wind a piece of 25cm*5cm*2mm self-adhesive coiled material at a distance of 6cm from the end of the membrane tow to plug the hole. Put the membrane filaments into the membrane module cylinder, put them into the suitable mold together, add polyurethane adhesive to 2cm beyond the end face of the membrane module cylinder, take off the mold after the epoxy glue is cured, and remove the excess along the membrane module cylinder. Remove the sealing material, and then add soft epoxy resin glue to the membrane module cylinder to submerge the protective layer by 2cm, until the epoxy resin glue is cured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com